Method for producing anti-pilling acrylic fiber

A technology of anti-pilling acrylic fiber and a manufacturing method, applied in the field of acrylic fiber manufacturing, can solve the problems that fibers cannot maintain physical properties, difficult to obtain anti-pilling acrylic fiber products, and high porosity of primary fibers, and achieve the effect of excellent physical performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0022] Manufacture the anti-pilling acrylic fiber that specification is 1.67dtex * 40mm according to the following steps:

[0023] 1) The spinning stock solution from the polymerization section passes through the spinneret assembly and the coagulation bath to form nascent fibers, the concentration of the spinning solvent sodium thiocyanate aqueous solution is 12wt%, and the total solid content of the spinning stock solution is 13wt%;

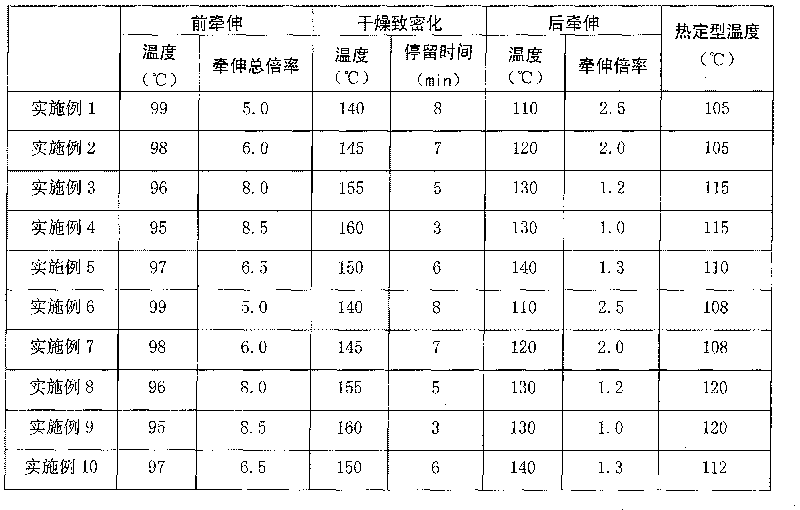

[0024] 2) As-spun fibers are subjected to graded heating and drawing (pre-drawing), and the drawing temperature and the total drawing ratio are shown in Table 1;

[0025] 3) The fibers are rinsed with hot water at a temperature of 65-75°C;

[0026] 4) The fiber is heated, dried and densified by hot air under tension, and the temperature of hot air and the residence time of drying and densification are shown in Table 1;

[0027] 5) After the fiber is heated and drawn (after drawn), the drawing temperature and the drawing ratio are shown in Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com