Grain warehouse electrical automation control system

A control system and electrical automation technology, applied in electrical program control, comprehensive factory control, fruit suspension devices, etc., can solve the problems of waste of resources, long distance between the machine room and the warehouse, and great danger, and achieve the reduction of labor intensity, scientific and efficient. The effect of supervision and management, remote operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

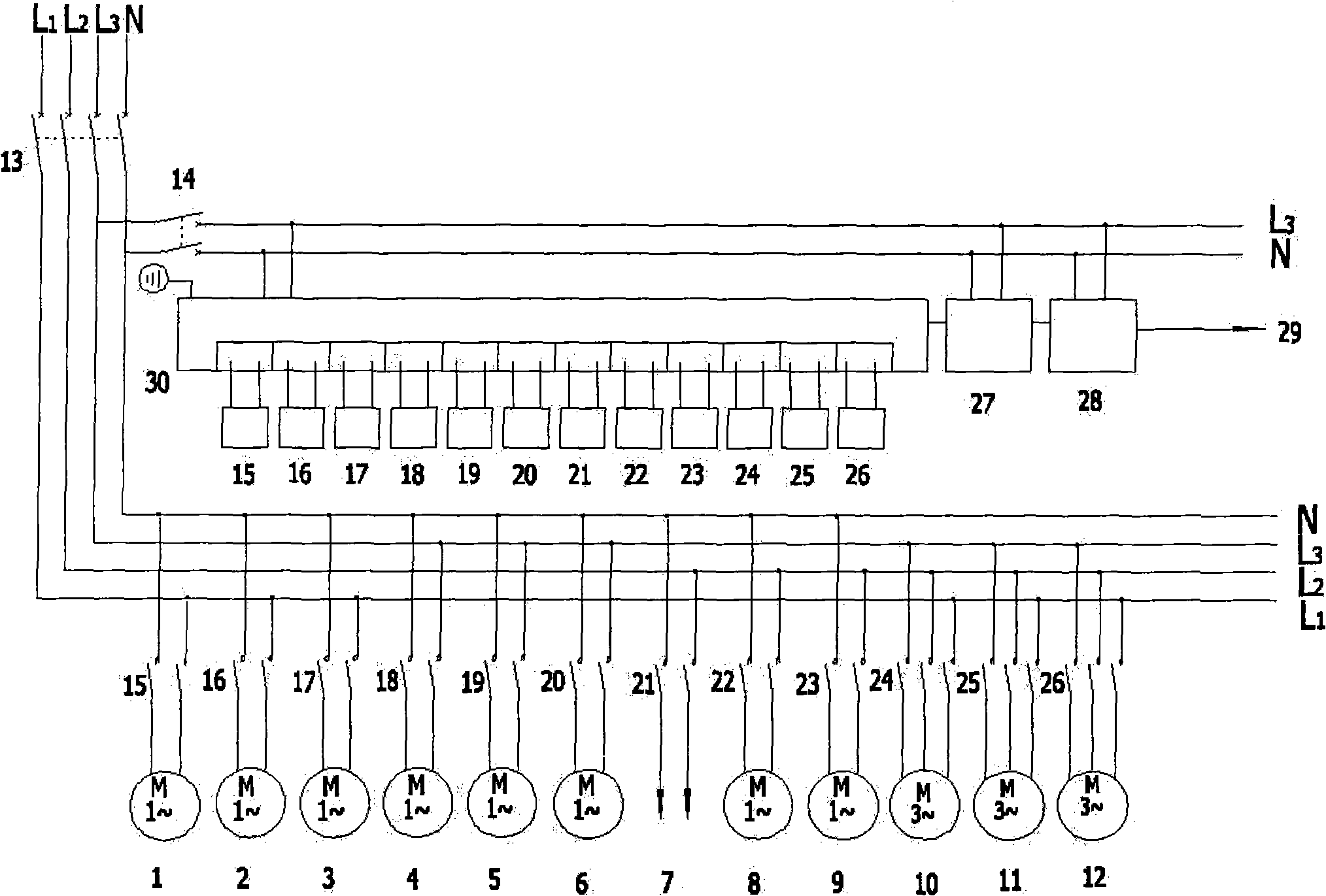

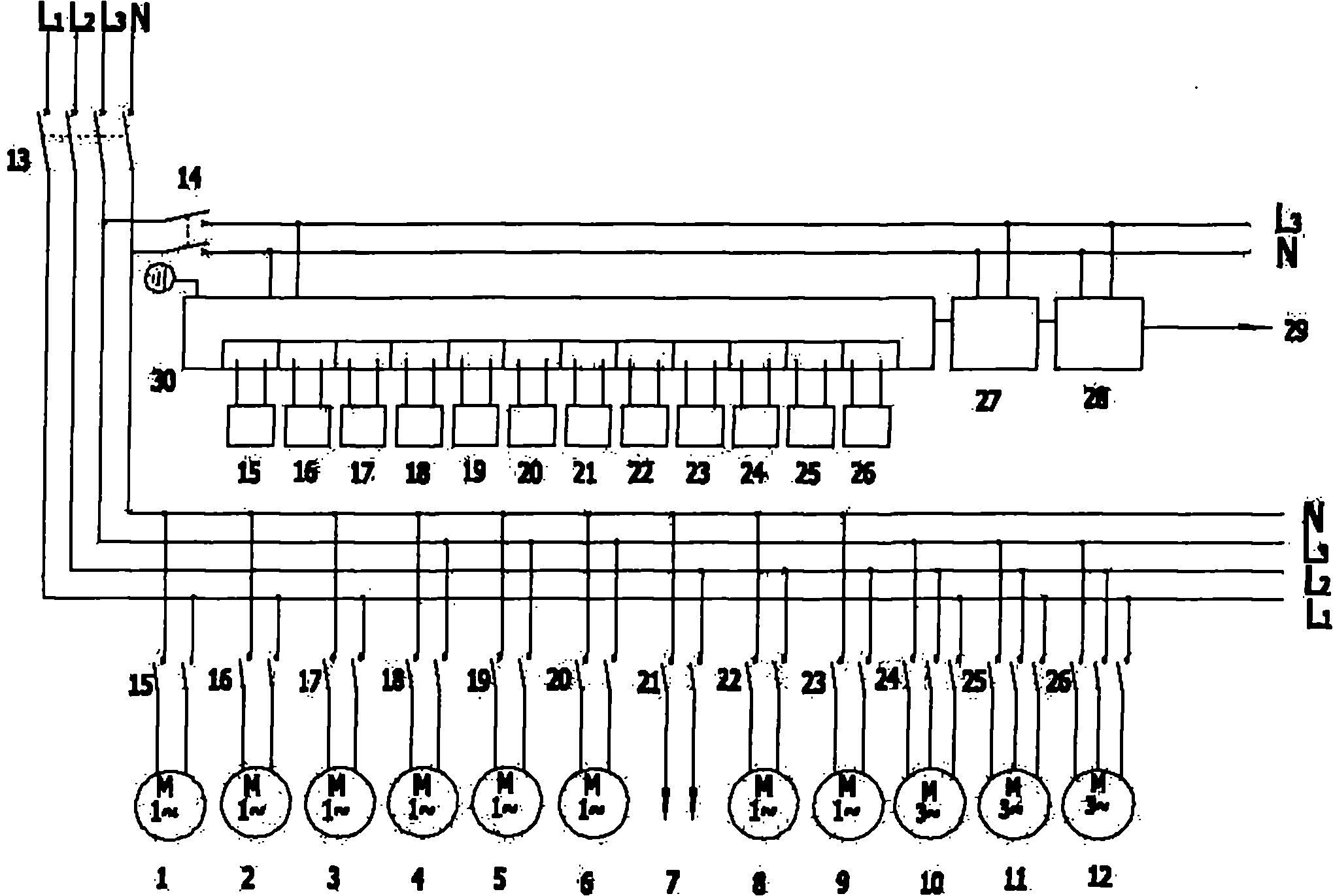

[0011] The following is a further detailed description of the electrical automation control system of the granary room in conjunction with the attached drawings:

[0012] With reference to the accompanying drawings, the electrical automation control system of the granary room of the present invention uses a computer (29) network system to automatically control the intelligent power distributor (30) in the box through an independent electrical appliance outside each granary to inflate the granary's nitrogen The electrical equipment related to the operation system of the operation system, gas circulation in the warehouse, grain condition detection and monitoring, and granary ventilation are remotely and automatically controlled.

[0013] Nitrogen gas filling operation system: the nitrogen generated from the machine room reaches each granary through the conveying pipe network. The air inlet valve (1) installed in the electrical automation control system of the granary room of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com