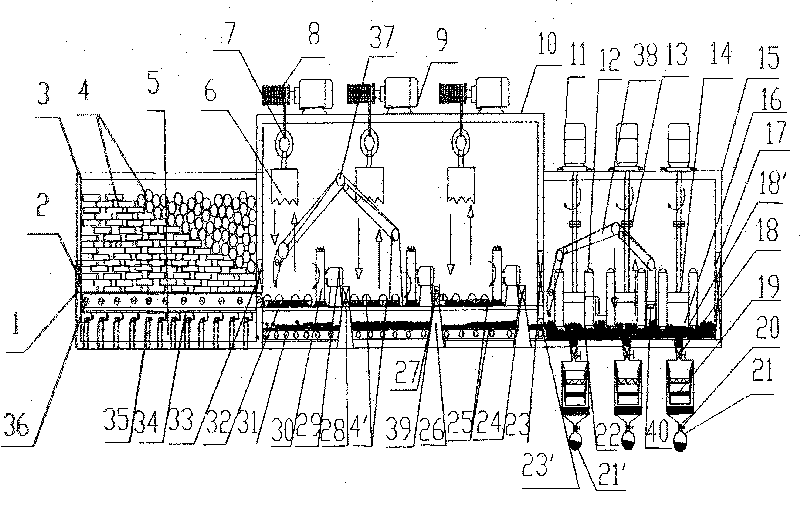

Production line for processing waste rubber and old tire into rubber powder and technology thereof

A process technology and waste rubber technology, applied in the field of processing waste rubber and old tires into rubber powder assembly line and process technology, can solve the problems of high energy consumption, small processing capacity, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0096] 2. Use 50% fine rubber powder containing waste rubber and old tires, polypropylene 14.25%, high-density polyethylene 14.25%, low-density polyethylene 11.11%, acetone 0.03%, sodium hydroxide 0.06%, glass fiber A mixture of 5.63%, 1.5% ammonium phosphate, 3.05% starch and 0.12% pigment, heated at 300°C for 3 minutes, can be molded into flat plates or paving stones. The material made by this method has good strength and smooth surface.

[0097] The application of equipment, process technology, and methods for processing waste rubber and old tires into rubber powder production line and process technology, after 300 days of long cycle, full load, safe, efficient, and environmentally friendly operation, will be able to deal with more than 13,000 Tons of waste rubber and old tires are processed, and more than 10,000 tons of rubber powder and thousands of tons of waste steel are obtained, which brings considerable economic and social benefits to technology, enterprises, and societ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com