Production process of high-purity nerchinskite

A production process, kaolin technology, applied in the direction of aluminum silicate, silicate, etc., can solve the problems of halloysite purification and production process that have not been reported, and achieve the effect of low production cost, simple process flow and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

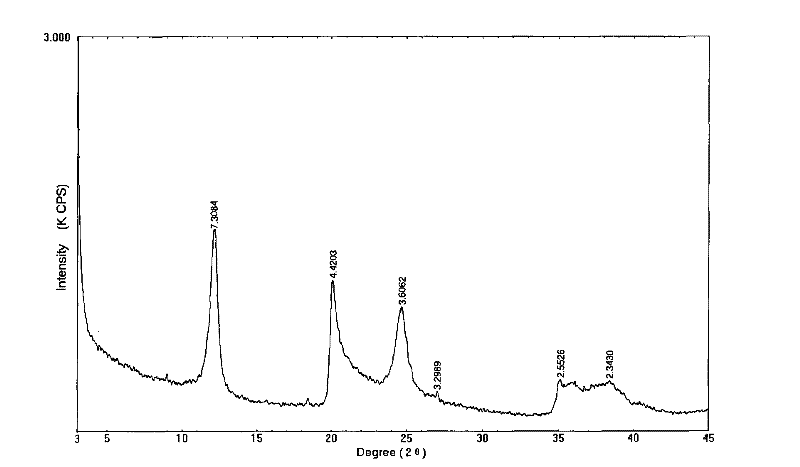

Embodiment 1

[0025] A production process of high-purity halloysite, it comprises the steps:

[0026] 1) Pounding: Use a high-pressure water gun to wash the raw ore of kaolin into the mashing pool, and the mashing pool is stirred by a biaxial agitator to obtain a kaolin slurry with a mass percentage of kaolin content of 25%; the mass percentage of halloysite in the kaolin raw ore is Content greater than 30%;

[0027] 2) Primary classification: Use a sand pump to pump the kaolin slurry obtained in step 1) to a cone classifier for primary classification to remove large particles of impurities such as feldspar and quartz. There are three groups of cone classifiers, and the three groups of cone classifiers are arranged in series , the underflow of the cone classifier is discharged as tailings, and the overflow of the last cone classifier passes through a 200-mesh vibrating screen and enters the first slurry storage tank to concentrate to obtain the pulp A. The mass percentage of kaolin in the p...

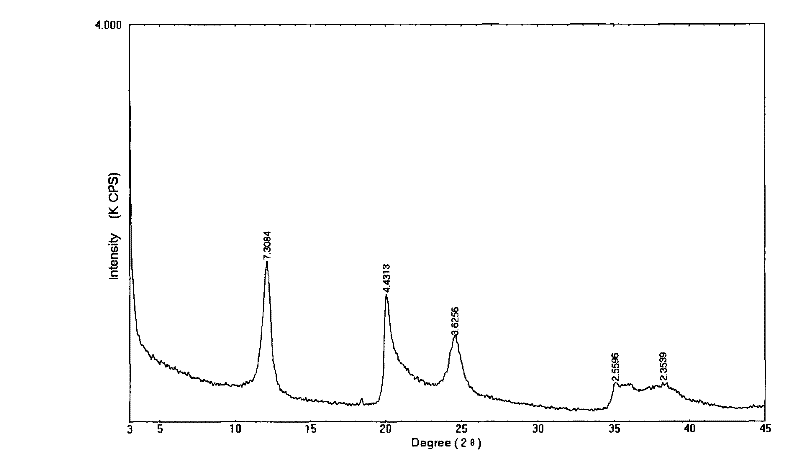

Embodiment 2

[0034] A production process of high-purity halloysite, it comprises the steps:

[0035] 1) Pounding: Use a high-pressure water gun to wash the raw ore of kaolin into the mashing tank, and the mashing tank is stirred by a biaxial agitator to obtain a kaolin slurry with a mass percentage of kaolin content of 28%; the mass percentage of halloysite in the kaolin raw ore is Content greater than 30%;

[0036] 2) Primary classification: Use a sand pump to pump the kaolin slurry obtained in step 1) to a cone classifier for primary classification to remove large particles of impurities such as feldspar and quartz. There are three groups of cone classifiers, and the three groups of cone classifiers are arranged in series , the underflow of the cone classifier is discharged as tailings, and the overflow of the last cone classifier passes through a 200-mesh vibrating screen and then enters the first slurry storage tank to concentrate to obtain the pulp A. The mass percentage of kaolin in ...

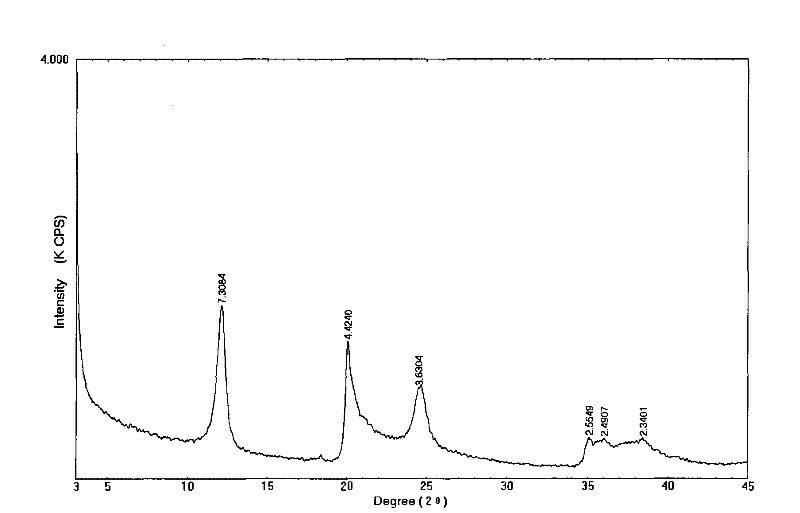

Embodiment 3

[0043] A production process of high-purity halloysite, it comprises the steps:

[0044] 1) Pounding: Use a high-pressure water gun to wash the raw ore of kaolin into the mashing pool, and the mashing pool is stirred by a biaxial agitator to obtain a kaolin slurry with a mass percentage of kaolin content of 30%; the mass percentage of halloysite in the kaolin raw ore is Content greater than 30%;

[0045] 2) Primary classification: Use a sand pump to pump the kaolin slurry obtained in step 1) to a cone classifier for primary classification to remove large particles of impurities such as feldspar and quartz. There are three groups of cone classifiers, and the three groups of cone classifiers are arranged in series , the underflow of the cone classifier is discharged as tailings, and the overflow of the last cone classifier passes through a 200-mesh vibrating screen and then enters the first slurry storage tank to concentrate to obtain the pulp A. The mass percentage of kaolin in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com