Carborundum ceramics manufacturing method based on novel nanometer four-component sintering additives

A technology of silicon carbide ceramics and sintering aids, which is applied in the field of silicon carbide ceramics manufacturing, can solve the problems of increasing the diffusion coefficient of silicon carbide atoms, reducing the sintering temperature, complex and low efficiency, etc. grain growth and avoid the effect of ball milling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

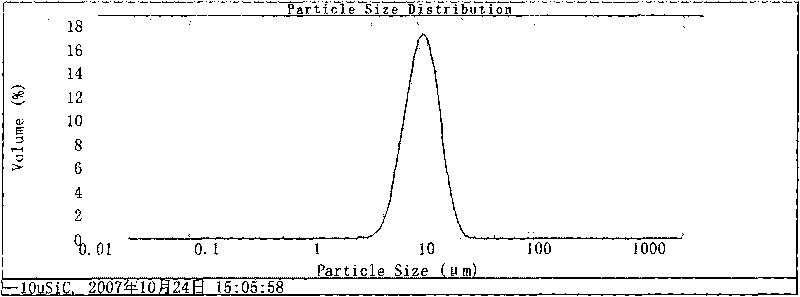

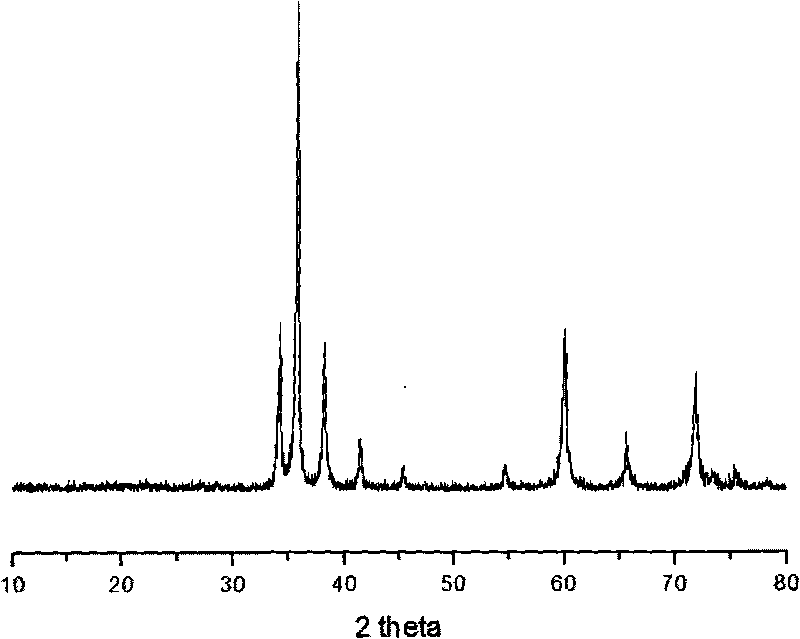

Embodiment 1

[0022] Embodiment 1: get nanometer MgO: nanometer La 2 o 3 : Nano Al 2 o 3 : Nano Y 2 o 3 Mass ratio=0.15:0.15:0.3:0.4 mixture (accounting for 10% of the total mass of the precursor powder) mixed with 88wt% silicon carbide powder, 2wt% phenolic resin, and the same weight of water at room temperature to form a suspension, after electric stirring After stirring for 5 minutes, a 1000W high-power ultrasonic transducer was inserted into the suspension, and the position of the ultrasonic probe was 3 cm below the liquid surface. Start the ultrasonic generator, a pulse period is 3 seconds, the working time is 2 seconds, the idle time is 1 second, and the working time is 20 minutes. The obtained suspension was filtered, dried at 80°C for 2 hours, crushed and sieved, put into a cylindrical mold and left to stand at 230Mpa for 5 minutes to obtain a green body. The green body was heat treated at 250°C for 20 minutes to remove the binder. Place the biscuit in a vacuum carbon tube fu...

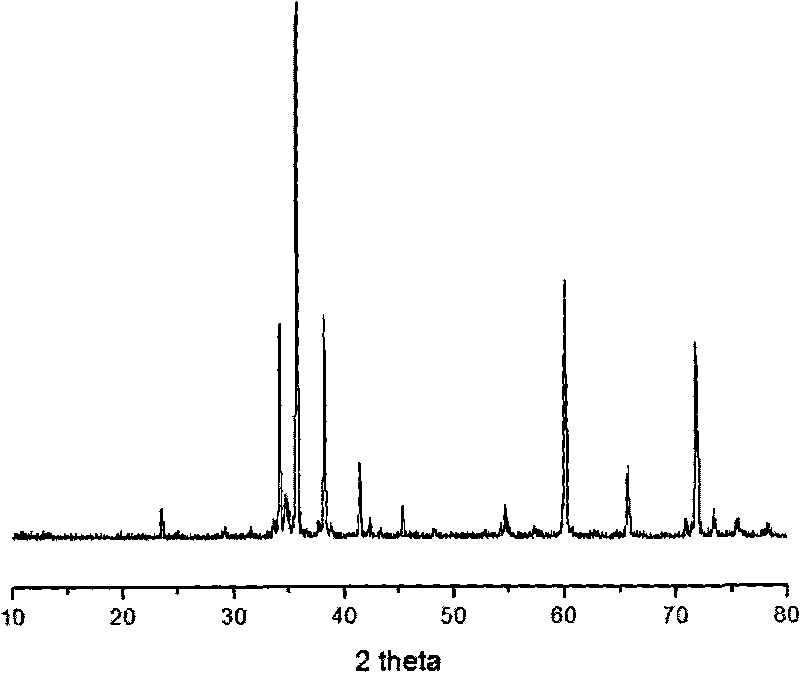

Embodiment 2

[0023] Embodiment 2: get nanometer CaO: nanometer Ce 2 o 3 : Nano Al 2 o 3 : Nano Y 2 o 3 Mass ratio=0.2:0.2:0.4:0.2 The mixture (accounting for 5% of the total mass of the precursor powder) is mixed with 90wt% silicon carbide powder, 5wt% phenolic resin, and the same weight of water at room temperature to form a suspension, which is stirred electrically After stirring for 5 minutes, a 1500W high-power ultrasonic transducer was inserted into the suspension, and the position of the ultrasonic probe was 3 cm below the liquid surface. Start the ultrasonic generator, a pulse period is 5 seconds, the working time is 2 seconds, the idle time is 3 seconds, and the working time is 20 minutes. The obtained suspension was filtered, dried at 80°C for 2 hours, crushed and sieved, put into a cylindrical mold and left to stand at 250Mpa for 5 minutes to obtain a green body. The green body was heat treated at 250°C for 20 minutes to remove the binder. Place the biscuit in a vacuum car...

Embodiment 3

[0024] Embodiment 3: get nanometer BaO: nanometer Lu 2 o 3 : Nano Al 2 o 3 : Nano Y 2 o 3 Mass ratio=0.3:0.3:0.2:0.2 The mixture (accounting for 15% of the total mass of the precursor powder) is mixed with 83wt% silicon carbide powder, 2wt% PVA, and the same weight of water at room temperature to form a suspension, which is passed through an electric stirrer After stirring for 5 minutes, a 2000W high-power ultrasonic transducer was inserted into the suspension, and the position of the ultrasonic probe was 3 cm below the liquid surface. Start the ultrasonic generator, a pulse period is 5 seconds, the working time is 2 seconds, the idle time is 3 seconds, and the working time is 20 minutes. The obtained suspension was filtered, dried at 80°C for 2 hours, crushed and sieved, put into a cylindrical mold and left to stand at 250Mpa for 5 minutes to obtain a green body. The green body was heat treated at 250°C for 20 minutes to remove the binder. Place the biscuit in a vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com