Antibacterial nano-silver composite polyurethane material and preparation method thereof

A composite polyurethane and nano-silver technology, which is applied in the field of food antibacterial packaging, can solve the problems of harmfulness to the human body, poor thermal stability, and poor durability, and achieve the effects of saving raw materials, facilitating operation, and simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

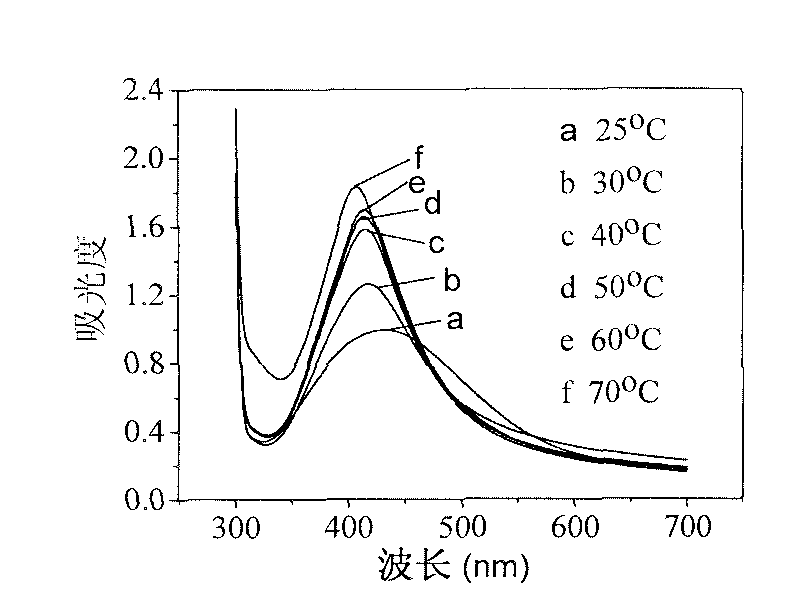

[0022] Embodiment 1: add 22mL concentration and be the N of 11% polyurethane in the there-necked flask, N-dimethylformamide-tetrahydrofuran (volume ratio is 4: 1) solution, slowly add 0.5% silver nitrate (relative to In polyurethane) N,N-dimethylformamide solution 4mL. Stir at room temperature for 0.5-1 hour. Gradually raise the temperature to 70°C, and continue to stir for 16 hours, and a golden yellow silver sol is seen to be formed. After the reaction solution is cooled, let it stand for 24 hours, bottle it and seal it or spin it into fibers. Wherein the silver nanoparticles have an average diameter of 10-100nm. ( figure 1 (UV-Vis absorption diagram)

Embodiment 2

[0023] Example 2: Take 20 mL of polyurethane N, N-dimethylformamide solution with a concentration of 8%, slowly add 0.5% silver nitrate (relative to polyurethane) N, N-dimethylformamide solution 3 mL under stirring. Stir at room temperature for 0.5-1 hour. Gradually raise the temperature to 60°C, and continue to stir for 16 hours, and a golden yellow silver sol is seen to be formed. After the reaction solution is cooled, let it stand for 24 hours, bottle it and seal it or spin it into fibers. Wherein the silver nanoparticles have an average diameter of 10-100nm.

example 3

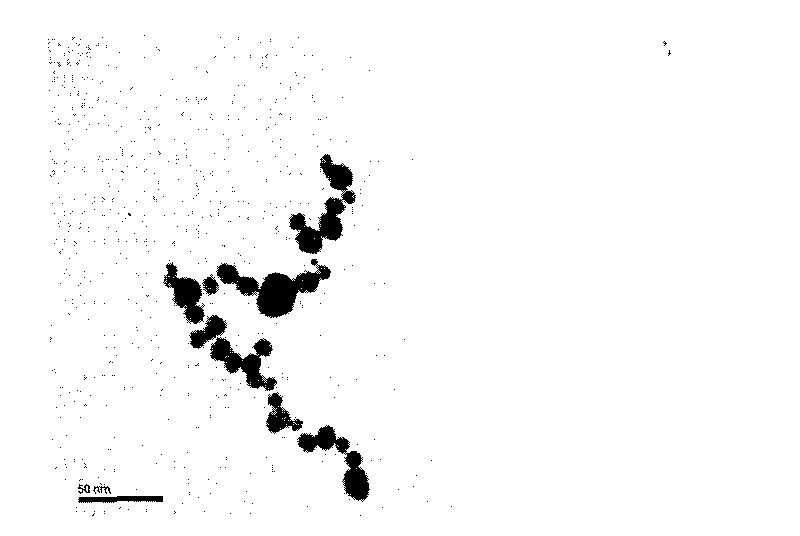

[0024] Example 3: Take 21.75 mL of 5% polyurethane N,N-dimethylformamide solution, slowly add 0.05% silver nitrate (relative to polyurethane) N,N-dimethylformamide solution 1 mL under stirring. Stir at room temperature for 0.5-1 hour. Gradually raise the temperature to 60°C, and continue to stir for 16 hours, and a golden yellow silver sol is seen to be formed. After the reaction solution is cooled, let it stand for 24 hours, bottle it and seal it or spin it into fibers. Wherein the silver nanoparticles have an average diameter of 10-100nm. ( figure 2 for transmission electron microscope)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com