Gallate luminous material and preparation method thereof

A luminescent material and gallate technology, applied in the field of luminescent materials, can solve the problems of limited application in the field of lighting and display, low luminous efficiency, etc., and achieve the effects of improved luminous efficiency, fewer process steps, and good luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 sol-gel method prepares La 0.995 GaO 3 :Tm 0.005 , Ag 0.0001

[0031] Weigh 6.4610g La(NO 3 ) 3 ·6H 2 O and 6.4556g Ga(NO 3 ) 3 ·XH 2 O (Ga content 16.2%) was placed in the container, and then 50 mL of a mixed solution of ethanol and water with a volume ratio of 4:1 was added, and 0.75 mL of Tm with a concentration of 0.1 mol / L was added under the condition of stirring in a water bath at 80 °C. 3+ solution, 0.15 mL of AgNO with a concentration of 0.01 mol / l 3 Solution, 8.6463g citric acid and 2.5g polyethylene glycol were stirred for 2 hours to obtain a uniform and transparent precursor sol.

[0032] Dry the precursor sol at 70°C for 20 hours to evaporate the solvent to obtain a xerogel, then grind the obtained xerogel into powder, put it into a high-temperature box furnace and raise the temperature to 800°C at a rate of 60°C / h, at this temperature Calcined at a constant temperature for 8 hours to obtain the blue-emitting La 0.995 GaO 3 :Tm 0....

Embodiment 2

[0033] Embodiment 2 sol-gel method prepares La 0.99 GaO 3 :Tm 0.01 , Ag 0.0005

[0034] Weigh 0.8064g La 2 o 3 and 0.4686g Ga 2 o 3 , heat and dissolve 1.1mL concentrated nitric acid and 1mL deionized water in the container, add 50mL mixed solution of ethanol and water with a volume ratio of 3:1 after cooling, add 0.5mL concentration of 0.1mol / L's Tm 3+ solution, 2.5 mL of Ag nanomicelle solution with a concentration of 0.001 mol / L, 4.8035 g of citric acid and 5 g of polyethylene glycol, and stirred for 4 hours to obtain a uniform and transparent precursor sol.

[0035] Dry the precursor sol at 150°C for 6 hours to evaporate the solvent to obtain a xerogel, then grind the obtained xerogel into powder, put it into a high-temperature box furnace and raise the temperature to 1100°C at a rate of 500°C / h, at this temperature Calcined at constant temperature for 4h to obtain blue-emitting La 0.99 GaO 3 :Tm 0.01 , Ag 0.0005 Gallate luminescent material.

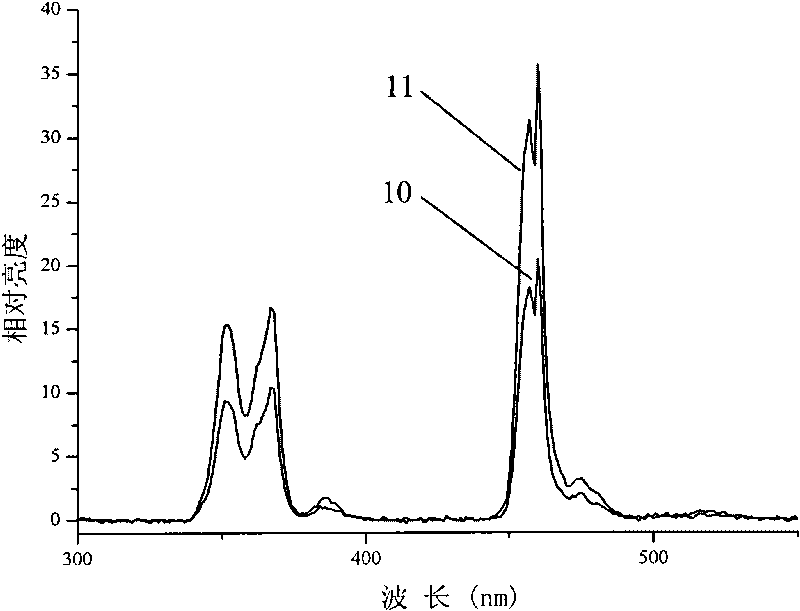

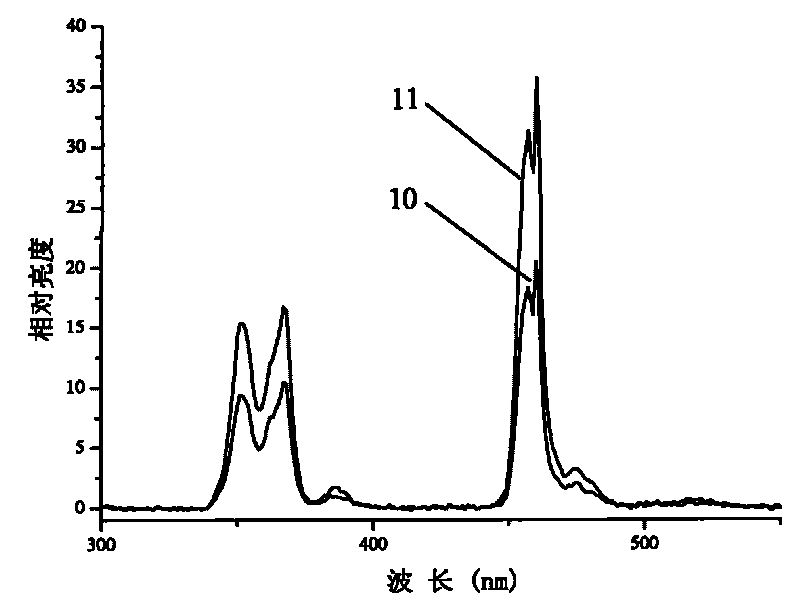

[0036] figur...

Embodiment 3

[0037] Embodiment 3 sol-gel method prepares La 0.995 GaO 3 :Tb 0.005 , Ag 0.00005

[0038] Weigh 2.1537g La(NO 3 ) 3 ·6H 2 O and 2.1519g Ga(NO 3 ) 3 ·XH 2 O (Ga content 16.2%) was placed in the container, and then 50 mL of a mixed solution of ethanol and water with a volume ratio of 8:1 was added, and 0.25 mL of Tb with a concentration of 0.1 mol / L was added under the condition of stirring in a water bath at 70 ° C. 3+ solution, 0.25mL of Ag nanomicelle solution with a concentration of 0.001mol / L, 9.605g of citric acid and 5g of polyethylene glycol, and stirred for 4 hours to obtain a uniform and transparent precursor sol.

[0039] Dry the precursor sol at 120°C for 8 hours to evaporate the solvent to obtain a xerogel, then grind the obtained xerogel into powder, put it into a high-temperature box furnace and raise the temperature to 1350°C at a rate of 300°C / h, at this temperature Calcined at a constant temperature for 2 hours to obtain La which emits blue-white lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com