Gallate luminous material and preparation method thereof

A technology of light-emitting material and gallate, applied in the field of light-emitting materials, can solve the problems of limited application in lighting and display fields, low light-emitting efficiency, etc., and achieve the effects of improved light-emitting efficiency, fewer process steps, and good light-emitting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 sol-gel method prepares La 0.995 GaO 3 :Tm 0.005 , Ag 0.0001

[0031] Weigh 6.4610g La(NO 3 ) 3 ·6H 2 O and 6.4556g Ga(NO 3 ) 3 ·XH 2 O (Ga content 16.2%) was placed in the container, and then 50 mL of a mixed solution of ethanol and water with a volume ratio of 4:1 was added, and 0.75 mL of Tm with a concentration of 0.1 mol / L was added under the condition of stirring in a water bath at 80 °C. 3+ solution, 0.15 mL of AgNO with a concentration of 0.01 mol / l 3 Solution, 8.6463g citric acid and 2.5g polyethylene glycol were stirred for 2 hours to obtain a uniform and transparent precursor sol.

[0032] Dry the precursor sol at 70°C for 20 hours to evaporate the solvent to obtain a xerogel, then grind the obtained xerogel into powder, put it into a high-temperature box furnace and raise the temperature to 800°C at a rate of 60°C / h, at this temperature Calcined at a constant temperature for 8 hours to obtain the blue-emitting La 0.995 GaO 3 :Tm 0....

Embodiment 2

[0033] Embodiment 2 sol-gel method prepares La 0.99 GaO 3 :Tm 0.01 , Ag 0.0005

[0034] Weigh 0.8064g La 2 o 3 and 0.4686g Ga 2 o 3 , heat and dissolve 1.1mL concentrated nitric acid and 1mL deionized water in the container, add 50mL mixed solution of ethanol and water with a volume ratio of 3:1 after cooling, add 0.5mL concentration of 0.1mol / L's Tm 3+ solution, 2.5 mL of Ag nanomicelle solution with a concentration of 0.001 mol / L, 4.8035 g of citric acid and 5 g of polyethylene glycol, and stirred for 4 hours to obtain a uniform and transparent precursor sol.

[0035] Dry the precursor sol at 150°C for 6 hours to evaporate the solvent to obtain a xerogel, then grind the obtained xerogel into powder, put it into a high-temperature box furnace and raise the temperature to 1100°C at a rate of 500°C / h, at this temperature Calcined at constant temperature for 4h to obtain blue-emitting La 0.99 GaO 3 :Tm 0.01 , Ag 0.0005 Gallate luminescent material.

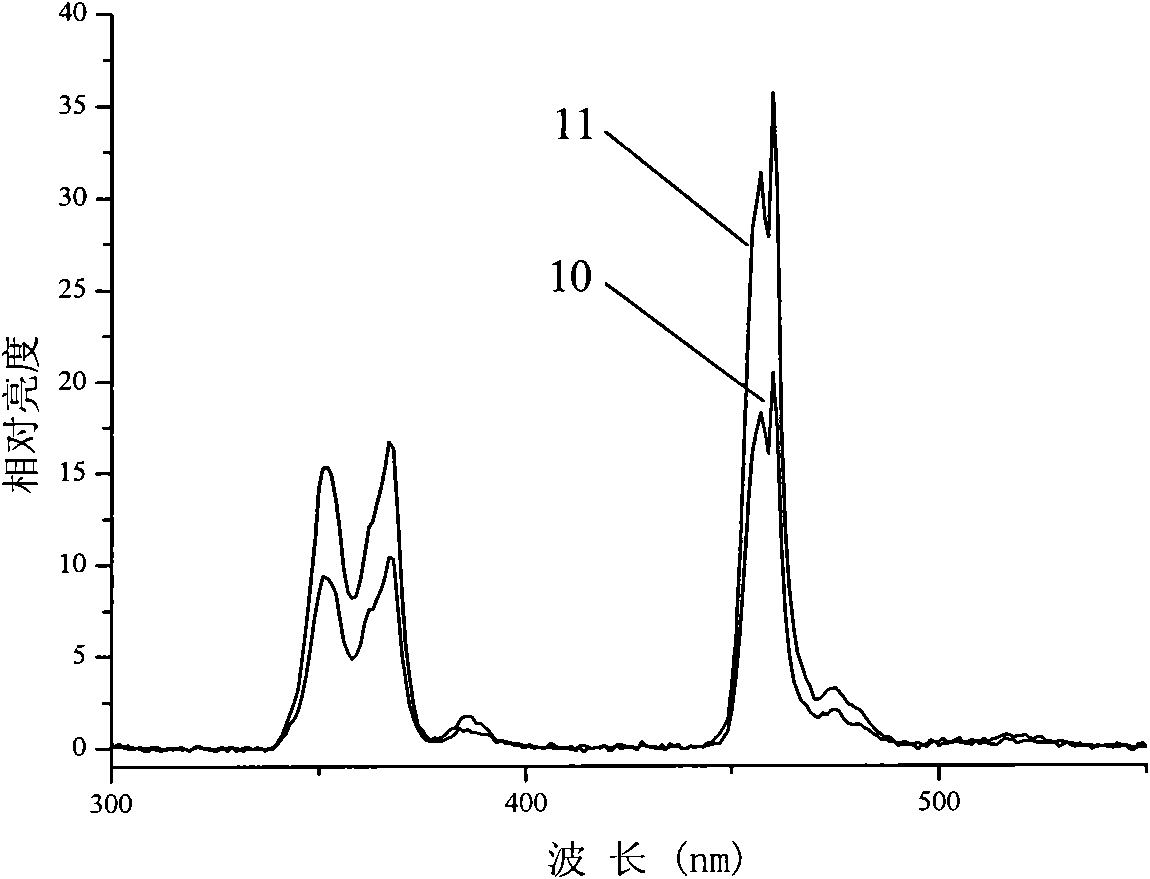

[0036] figur...

Embodiment 3

[0037] Embodiment 3 sol-gel method prepares La 0.995 GaO 3 :Tb 0.005 , Ag 0.00005

[0038] Weigh 2.1537g La(NO 3 ) 3 ·6H 2 O and 2.1519g Ga(NO 3 ) 3 ·XH 2 O (Ga content 16.2%) was placed in the container, and then 50 mL of a mixed solution of ethanol and water with a volume ratio of 8:1 was added, and 0.25 mL of Tb with a concentration of 0.1 mol / L was added under the condition of stirring in a water bath at 70 ° C. 3+ solution, 0.25mL of Ag nanomicelle solution with a concentration of 0.001mol / L, 9.605g of citric acid and 5g of polyethylene glycol, and stirred for 4 hours to obtain a uniform and transparent precursor sol.

[0039] Dry the precursor sol at 120°C for 8 hours to evaporate the solvent to obtain a xerogel, then grind the obtained xerogel into powder, put it into a high-temperature box furnace and raise the temperature to 1350°C at a rate of 300°C / h, at this temperature Calcined at a constant temperature for 2 hours to obtain La which emits blue-white lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com