Compositions and methods for cell killing

A cellular, biocidal technology, applied in the directions of botanical equipment and methods, chemicals for biological control, biocides, etc., that can solve the problem of insufficient reduction of bacteria, loss of activity, and no teaching of selective killing of polymer structures. type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

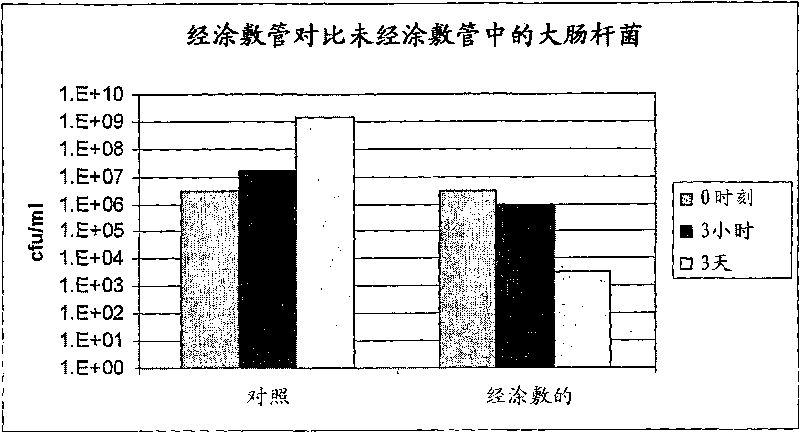

[0143] Comparison of Bacterial Production (E. coli) in TSB in NafionTM-Coated Vials vs. Uncoated Vials

[0144] Materials and methods

[0145] A 15 ml vial was coated with a commercial solution of Nafion™ (available from Du Pont) and allowed to dry. This resulted in the formation of a thin layer (approximately 50 microns) of polymerized Nafion™ on the inner surface of the vial.

[0146] Coated and uncoated vials were filled with 10 ml TSB and inoculated with E. coli (3×10 6 cfu / ml). The vials were then incubated statically at 30°C. At 0 hours, 3 hours and 3 days after inoculation, samples were taken from the bacterial broth and spread on TSA plates and incubated at 30°C for 24 hours for bacterial counts (cfu / ml).

[0147] result

[0148] figure 1 Represents the bacterial counts of E. coli in Nafion™-coated vs. uncoated vials; figure 2 A comparison of bacterial deposition in uncoated vials (left) and coated vials (right) is shown.

[0149] In uncoated controls, ba...

Embodiment 2

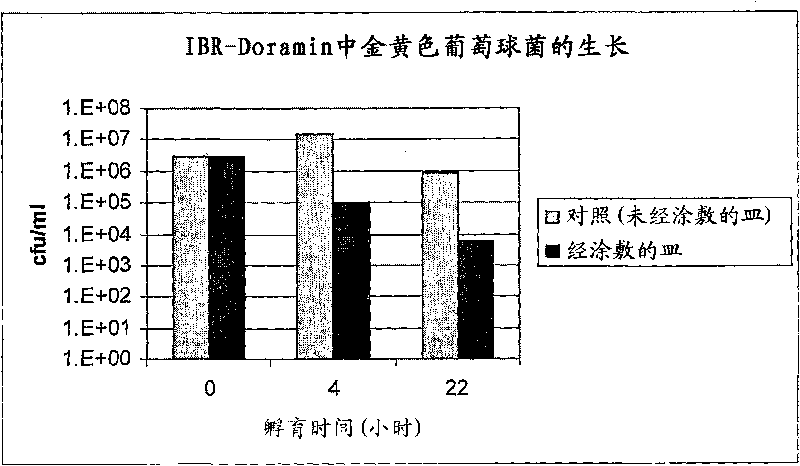

[0152] via Dormin TM Bacteria production in coated vs. uncoated vials

[0153] Dormenin, a natural extract from plants and plant organs in their dormant phase, slows cell proliferation, keeps the skin younger and healthier and provides the means for better skin protection. Dormantin is used by many cosmetic companies as an active ingredient in cosmetic creams and lotions. Dormenin is sensitive to bacterial and fungal contamination.

[0154] Materials and methods

[0155] In this test, 100 microliters of Staphylococcus aureus culture was mixed with 5.8×10 7 Concentration of cfu / ml added to 2ml preservative-free Dormin TM solution (from IBR, Rehovot, Israel). Dormin inoculated with Staphylococcus aureus TM The solution was placed in a Petri dish coated with a 50 micron thick layer of Nafion™. After 4 hours and 22 hours of incubation at 30°C, samples were plated on TSA plates and incubated at 30°C for 24 hours to monitor bacterial proliferation.

[0156] result

[01...

Embodiment 3

[0161] Bacterial Inhibition in Commercially Available Cosmetic Creams Without Parabens

[0162] Materials and methods

[0163] Commercially available paraben-free cosmetic cream samples were from IBR Ltd., Rehovot, Israel. The initial E. coli and Staphylococcus aureus cultures were grown on TSB at 30° C. for 4 hours and mixed with the cosmetic cream in a 1:1 ratio (8 ml of each culture mixed with 8 g of the cosmetic cream) and placed in In a dish coated with Nafion™. Bacterial production was monitored at 0, 24, 48, 72, 96, 144 and 168 hours of incubation at 30°C as described above.

[0164] result

[0165] Figure 5 Shows bacterial production in cosmetic creams in Nafion™ coated dishes; Image 6 Shows bacterial production in cosmetic creams in Nafion™ coated dishes.

[0166] Figure 5 with Image 6 It was shown that bacterial growth of cosmetic creams was strongly inhibited in Nafion™ coated dishes compared to uncoated dishes. In fact, E. coli and Staphylococcus a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com