Dry-process integrating method for purifying smoke and system used therefor

A flue gas and dry process technology, applied in chemical instruments and methods, separation methods, electrostatic effect separation, etc., can solve the problems of increasing power consumption and raw material consumption, poor dust removal efficiency, and high dust specific resistance, reducing power consumption. The effect of consumption, desulfurization, denitration and mercury removal is close to the temperature, and the consumption of raw materials is less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Treatment 1 discharge volume is 20000m 3 / h of acid plant tail gas.

[0044] SO in acid gas 2 The concentration is 20560mg / m 3 , NO x 100mg / m 3 .

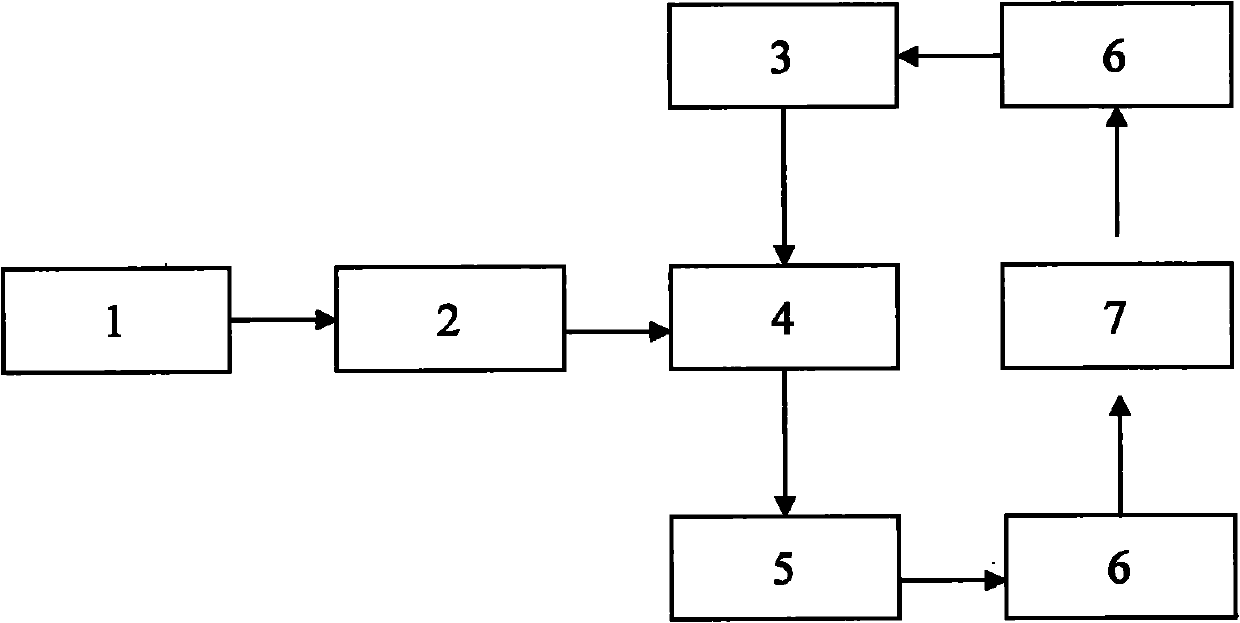

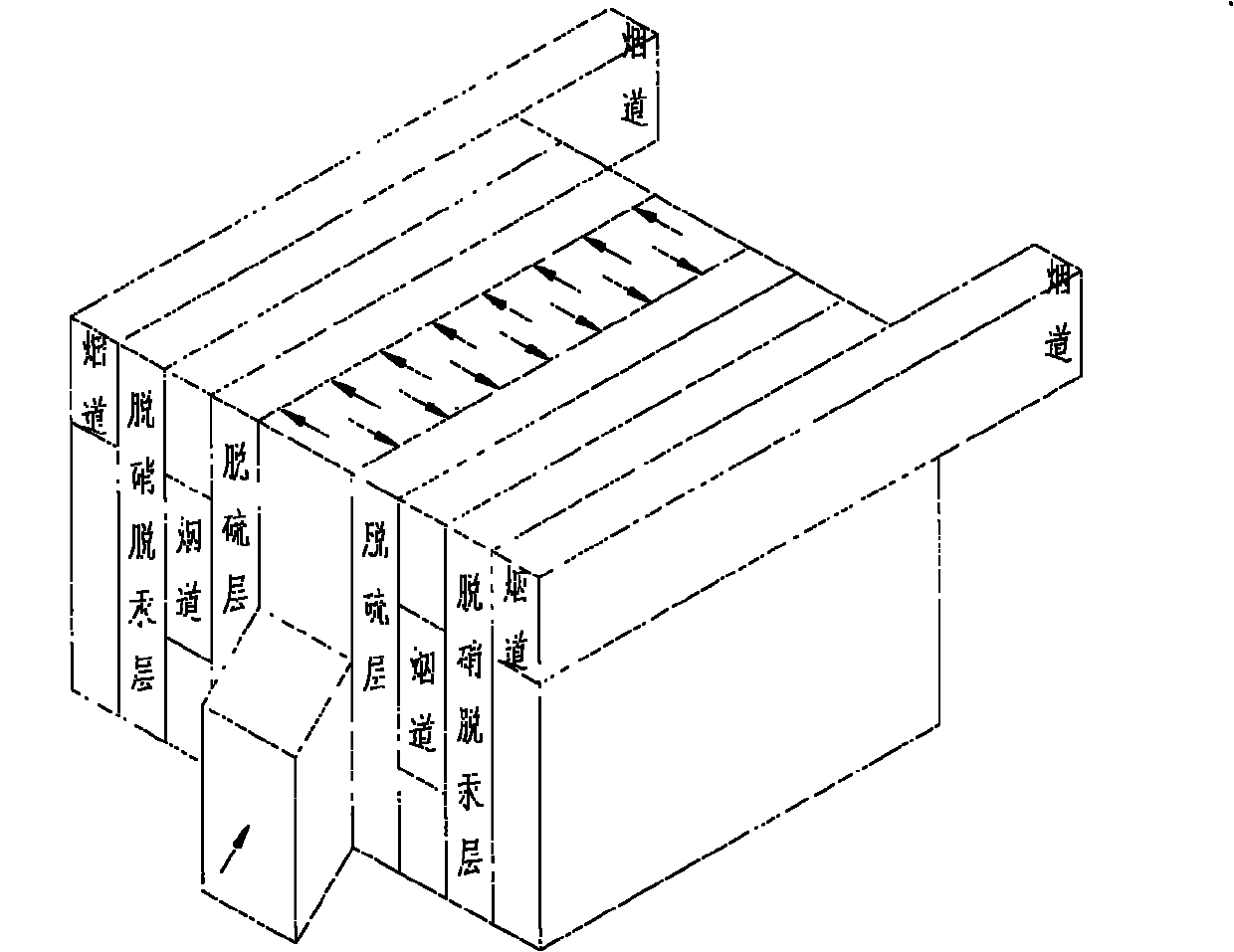

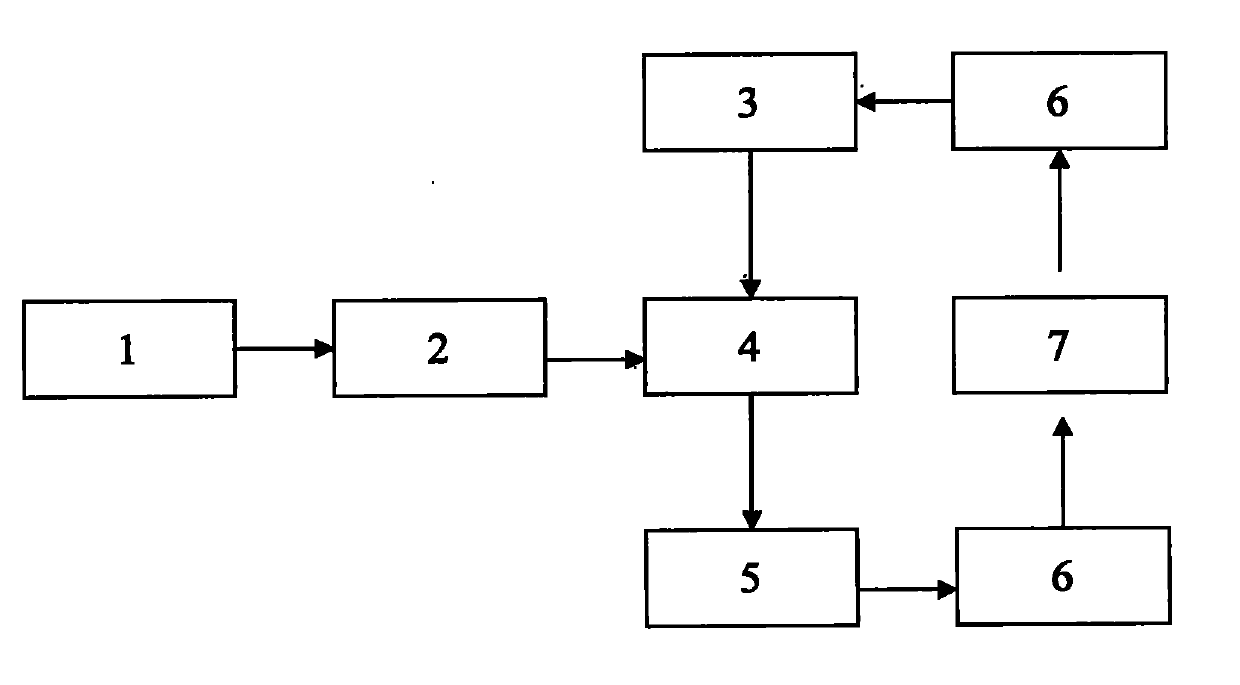

[0045] The sour gas first passes through the gas-gas heat exchange device 1 to exchange heat below 100°C, and then enters the low-temperature electrostatic precipitator 2 to remove 99.85% of the dust; The active coke under the bottom is in cross-flow contact, cleaned and emptied, and the deactivated active coke is discharged from the discharge device 5, and sent to the active coke regeneration device 7 through the conveying device 6 for regeneration.

[0046] Considering the high concentration of sulfur-containing gas in the sour gas, the space velocity is selected as 250h -1 , that is, the amount of active coke is 80m 3 . The moving speed of active coke in the cross-flow moving bed adsorption tower is 0.015m / s. The equipment has been in operation for 2 years, and it can meet the effective purification of acid gas, ...

Embodiment 2

[0048] Treatment of flue gas from a steam boiler. The flue gas emission is 8000m 3 / h.

[0049] SO in flue gas 2 The concentration is 2400mg / m 3 , NO x 500mg / m 3 .

[0050] The flue gas first passes through the gas-gas heat exchange device 1 to exchange heat below 100°C, and then enters the low-temperature electrostatic precipitator 2 to remove 99.85% of the dust; the flue gas after dust removal enters the cross-flow moving bed adsorption tower 4 and the top-down The active coke is cross-flow contacted, purified and then emptied, and the deactivated active coke is discharged from the discharge device 5, and sent to the active coke regeneration device 7 through the conveying device 6 for regeneration.

[0051] Considering that the content of harmful gases in the flue gas is low, the air speed is selected to be 800h -1 , that is, the amount of active coke is 10m 3 , the moving speed in the cross-flow moving bed adsorption tower is selected as 0.03m / s. The equipment has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com