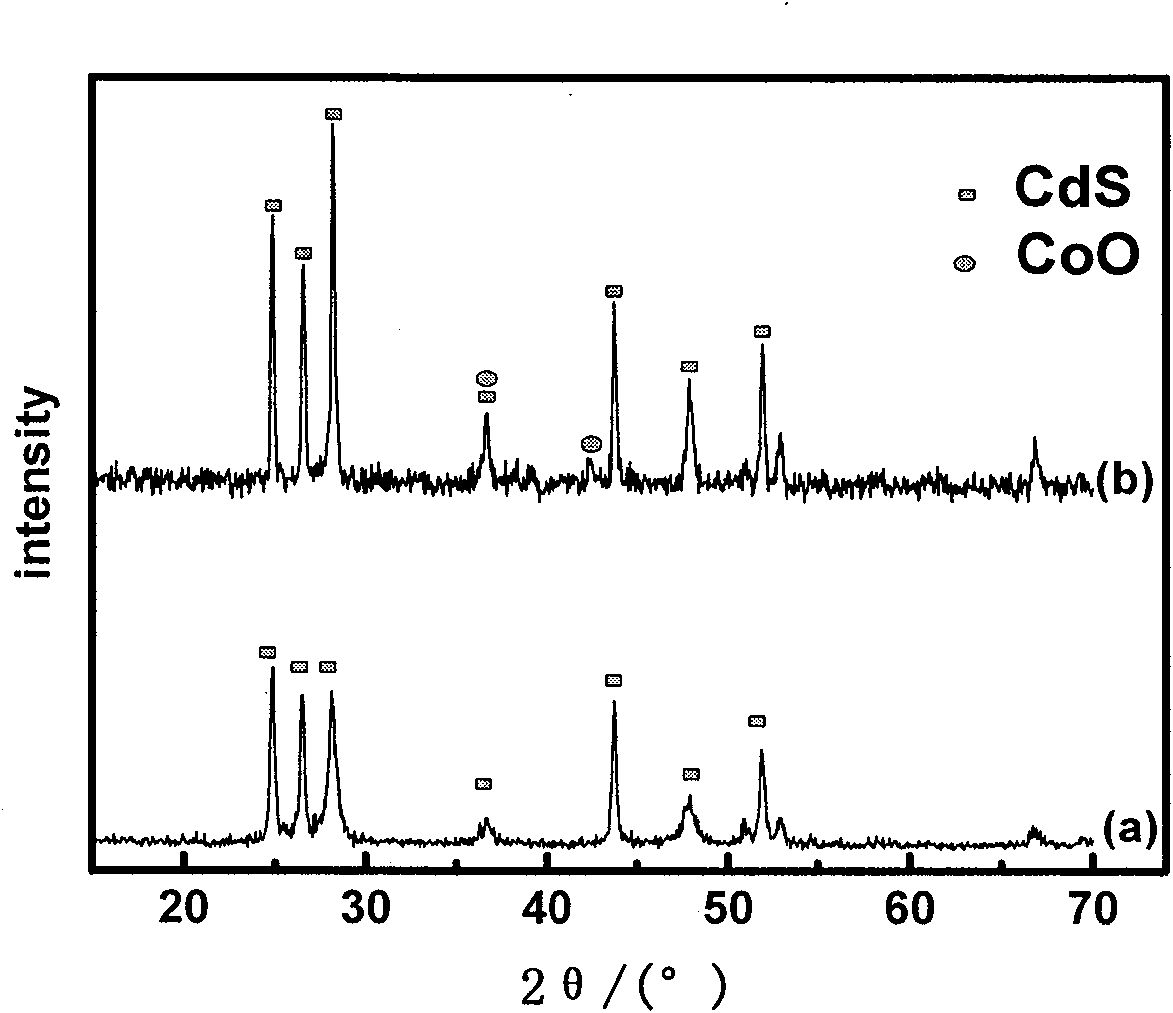

Method for preparing p-CoO/n-CdS compound semiconductor photocatalyst

A compound semiconductor and photocatalyst technology, applied in the field of photocatalytic materials, can solve problems that have not been reported in the literature, and achieve the effects of reducing photocorrosion, increasing specific surface area, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

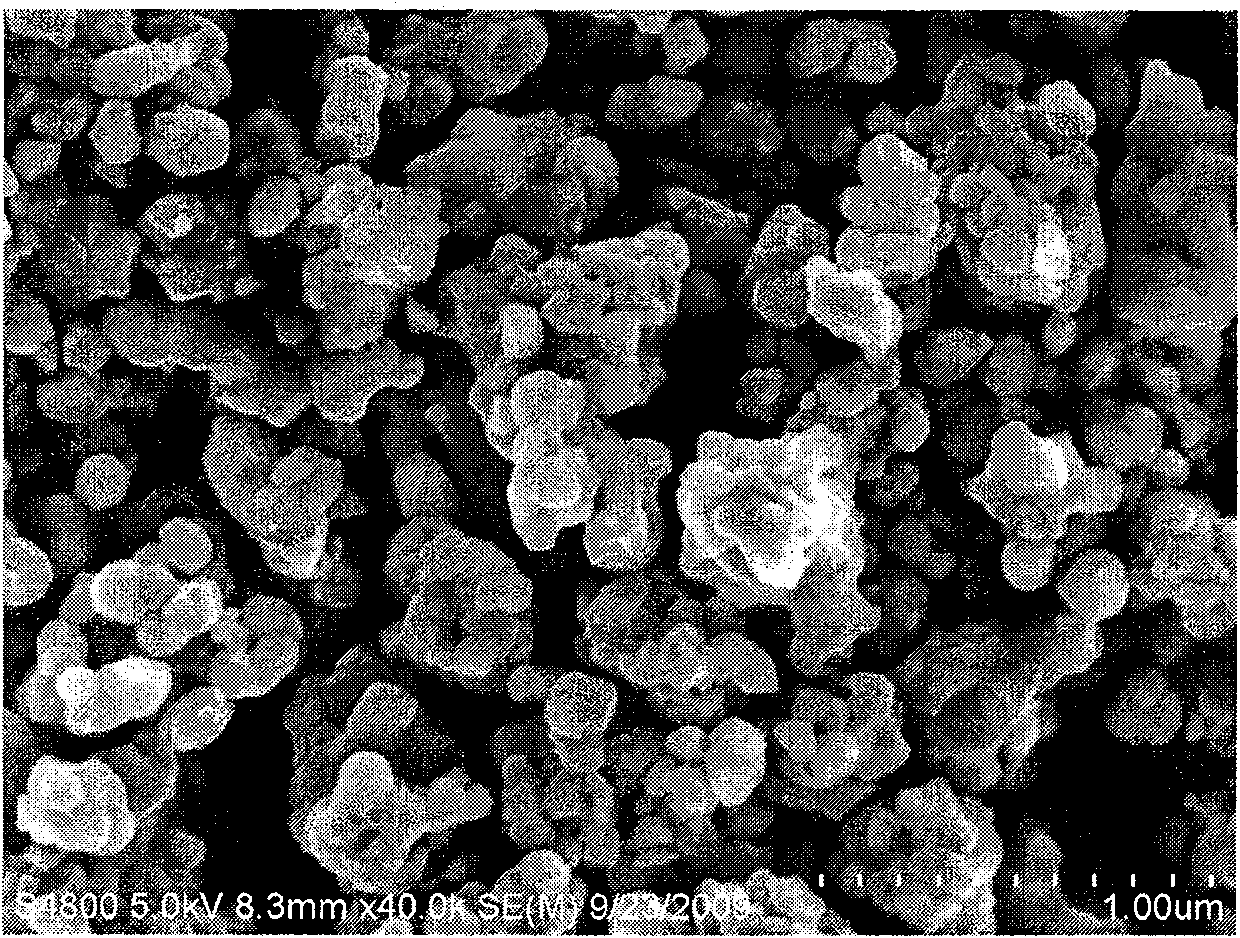

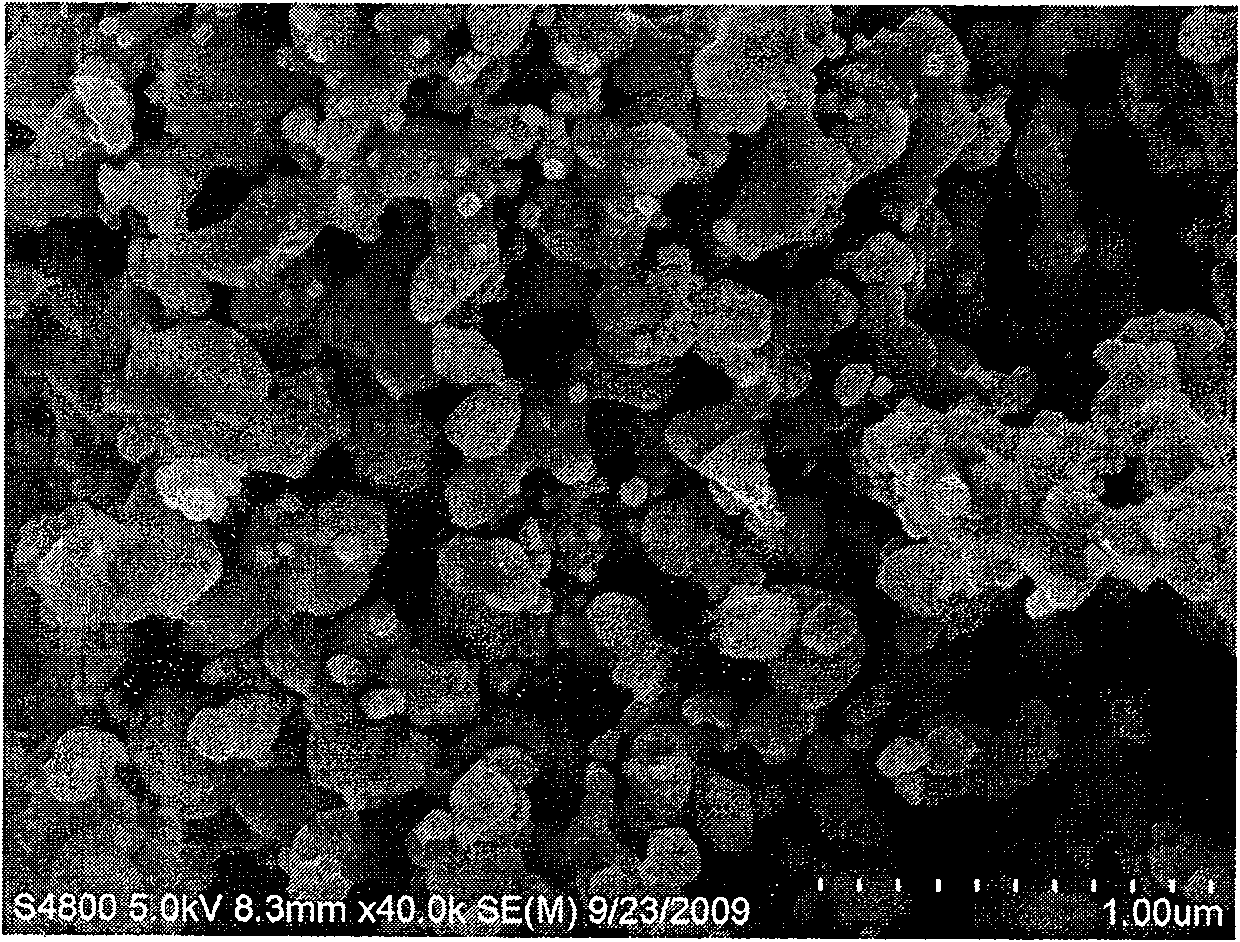

Method used

Image

Examples

Embodiment 1

[0035] Preparation of CdS solid powder product:

[0036] Anhydrous ammonium sulfate: 24%

[0037] Anhydrous cadmium sulfate: 11%

[0038] Thiourea: 5%

[0039] Deionized water: 60%

[0040] The preparation of CdS solid powder product is according to anhydrous ammonium sulfate: anhydrous cadmium sulfate: thiourea: the ratio by weight of deionized water is 24%: 11%: 5%: 60%, anhydrous ammonium sulfate, anhydrous sulfuric acid Mix cadmium, thiourea and deionized water, pre-react for 0.5h in a microwave reactor with a power of 500W, and then react at 80°C for 10h under ultrasonic dispersion with a frequency of 53KHZ and a power of 350W to obtain a reaction product; the reaction product After filtration, the yellow CdS primary solid powder cake was obtained; the CdS primary solid powder cake was added to deionized water 5 times its weight, washed with deionized water, ultrasonically dispersed for 1 hour and filtered, and the above operation was repeated three times to obtain the...

Embodiment 2

[0048] Preparation of CdS solid powder product:

[0049] Anhydrous Ammonium Chloride: 34.5%

[0050] Cadmium nitrate tetrahydrate: 15.4%

[0051] Thiourea: 7.1%

[0052] Deionized water: 50%

[0053] The preparation of CdS solid powder product is according to anhydrous ammonium chloride: cadmium nitrate tetrahydrate: thiourea: the ratio by weight of deionized water is 34.5%: 15.4%: 7.1%: 50%, anhydrous ammonium chloride, tetrahydrate Water cadmium nitrate, thiourea and deionized water are mixed, firstly reacted in a microwave reactor with a power of 300W for 1h, and then reacted at 90°C for 5h under ultrasonic dispersion with a frequency of 53KHZ and a power of 250W to obtain the reaction product; The product was filtered to obtain a yellow CdS primary solid powder cake; the CdS primary solid powder cake was added to deionized water 5 times its weight, washed with deionized water, ultrasonically dispersed for 1 hour and filtered, and the above operation was repeated three tim...

Embodiment 3

[0061] Preparation of CdS solid powder product:

[0062] Trimethylamine Sulfate: 12%

[0063] Anhydrous cadmium chloride: 12.8%

[0064] Thiourea: 10.2%

[0065] Deionized water: 65%

[0066] The preparation of CdS solid powder product is according to trimethylamine sulfate: anhydrous cadmium chloride: thiourea: the ratio by weight of deionized water is 12%: 12.8%: 10.2%: 65%, trimethylamine sulfate, anhydrous Mix cadmium chloride, thiourea and deionized water, pre-react in a microwave reactor with a power of 600W for 0.5h, and then react at 85°C for 4h under ultrasonic dispersion with a frequency of 53KHZ and a power of 200W to obtain a reaction product; The reaction product was filtered to obtain a yellow CdS primary solid powder cake; the CdS primary solid powder cake was added to deionized water 5 times its weight, washed with deionized water, ultrasonically dispersed for 1 hour and filtered, and the above operation was repeated three times to obtain a CdS secondary sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com