Material for preparing steel fiber brake pad

A technology for steel fibers and brake pads, applied in the field of materials for preparing steel fiber brake pads, can solve the problems of low stability of friction coefficient, high content of Mn and P, unfavorable friction pairs, etc., so as to avoid environmental pollution and human body. Effects of damage, stable friction coefficient, and high braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

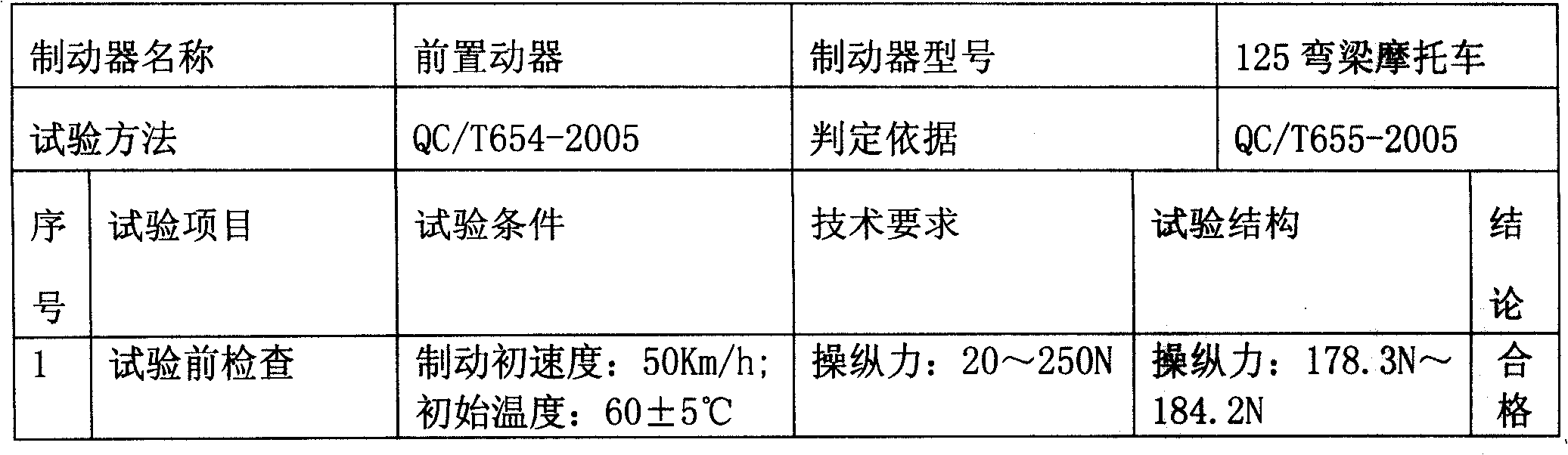

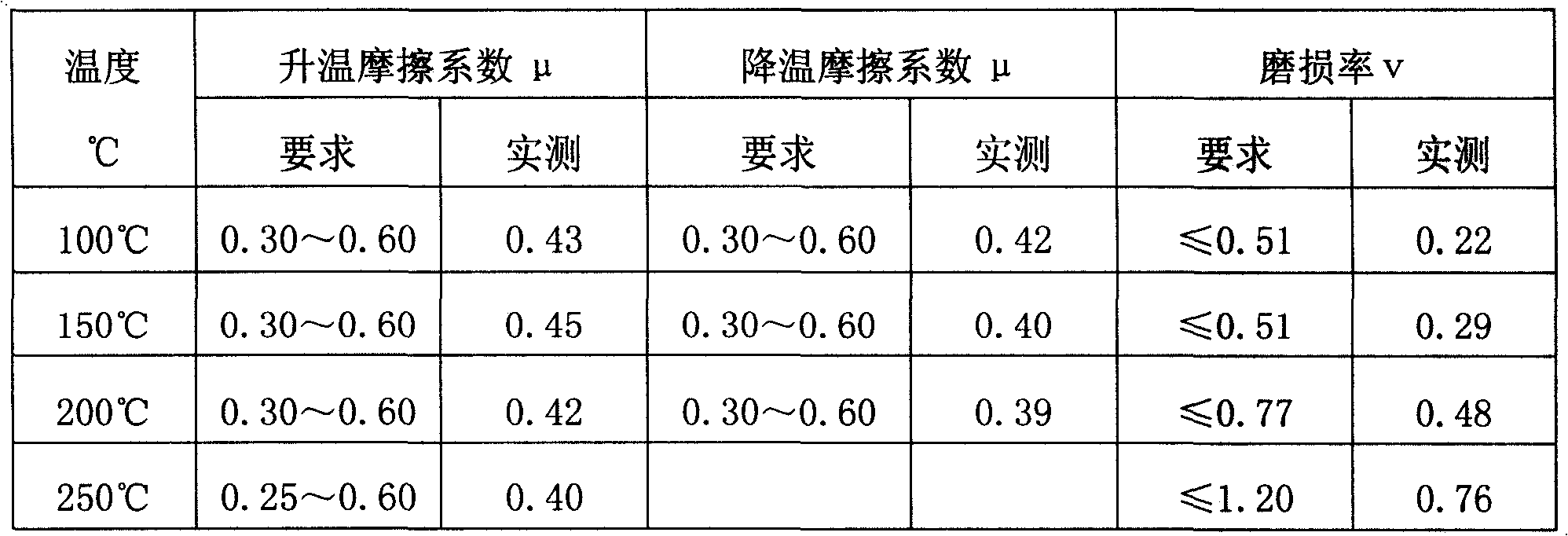

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are described in detail below:

[0035] Get the material of the present invention according to Table 1, and split the fibers in the bundled state into individual fibers with an open mill---ingredients---high-speed mixing---forming and pressing---cutting---grinding sheet--- -inspection---packing, and the non-asbestos steel fiber brake pad (brake pad) is obtained.

[0036] Table 1 (unit: gram)

[0037] sequence

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com