Extraction of lysozyme in egg white and comprehensive utilization of egg white protein

A technology of egg white lysozyme and egg white protein, which is applied in animal protein processing, enzymes, enzymes, etc., can solve problems such as unfavorable preparations, long drying time, and protein damage, and achieve the goals of reducing production costs, ensuring product quality, and high product vitality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

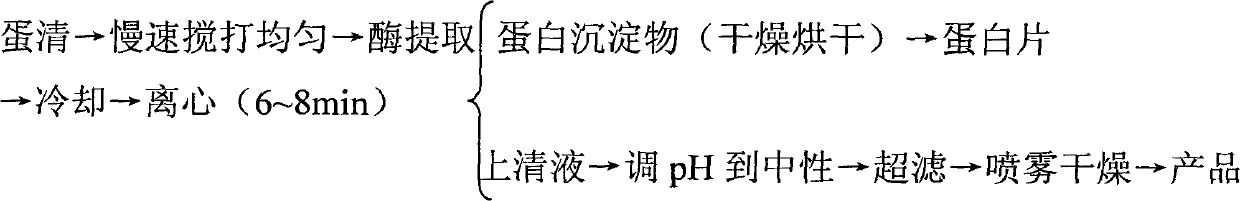

Method used

Image

Examples

example 1

[0028] (1) Extraction of lysozyme

[0029] Use a poultry egg (egg, duck or goose egg) separator to separate the egg yolk from the egg white, and beat the egg white mechanically until it is uniform and does not foam. Dissolve 2% food-grade hydrochloric acid or 6% lactic acid and 4% potassium chloride in purified water equal to the volume of egg whites, and then mix them evenly with egg whites at 75°C. The whole mixing process is controlled and completed within 10 minutes. After mixing the above mixture, keep it warm for 10 minutes, and then quickly cool it down to below 25°C. Centrifuge at 4000r / min for 7min. The supernatant was adjusted to neutral pH with food-grade NaOH. A hollow fiber ultrafiltration membrane with a cut-off of 11,000 is used, and the nitrogen pressure is controlled at 0.20MPa for ultrafiltration desalination and concentration. When concentrated to 1 / 8 of the original volume, it can still maintain 12.0L / min·m 2 Ultrafiltration speed and 89% desalination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com