Pine needle sectioning observation method

A technology of needles and pine trees, which is applied in the field of filming and observation of pine needles. It can solve the problems of high scraping operation requirements, difficulty in observing clearly, damage to leaf skin, etc., and achieves shortening filming time, clear display, and easy purchase. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The method for making sheets of the pine needle leaf epidermis of the present embodiment comprises the following steps

[0037] (1) Take off a piece of needle leaf, dip it in water and paste it on the surface of laundry soap, hold the laundry soap in your left hand or place it on the table, press the back of the needle leaf with your left thumb, and hold a single-sided blade in your right hand, after dipping in water , tilt the single-sided blade, and gently scrape off the upper part of the leaf along the leaf surface at an appropriate distance from the leaf tip (or the front end of the leaf segment). After scraping 1-3 times, re-wet the blade with water, and Remove the residue attached to the blade, and then continue to gently scrape off the upper part of the leaf with the blade, scrape off the upper epidermis and mesophyll cells of the leaf as much as possible, leaving only the lower epidermis of the leaf, laundry soap When the upper blade is gently scraped by the sin...

Embodiment 2

[0042] The method for making sheets of the pine needle leaf epidermis of the present embodiment (in order to observe the stomata profile) comprises the following steps

[0043] Step (1) and step (2) are the same as step (1) and step (2) in Example 1 for slicing and cleaning steps of the coniferous leaf epidermis;

[0044] (3) Transfer the washed leaf epidermis to a glass slide, and add dropwise a mixture of absolute ethanol and cedar oil (the volume ratio of absolute ethanol to cedar oil is 50:1), so that it completely covers the surface of the coniferous slices , use absorbent paper to absorb the white liquid that diffuses to the surroundings; when the mixed solution is almost volatilized, add the mixed solution of absolute ethanol and cedar oil dropwise, repeat 5 times; then add the mixed solution of absolute ethanol and cedar oil dropwise, and then Cover with a coverslip;

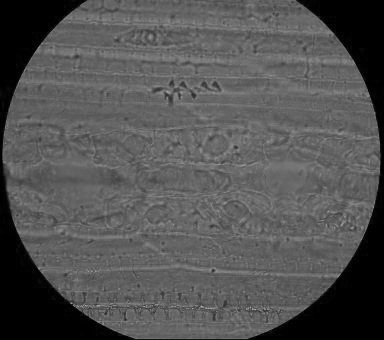

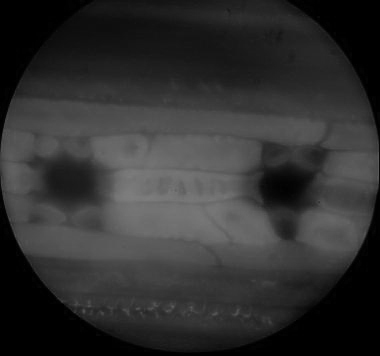

[0045] (4) Place the finished glass slide on the microscope stage, observe and take pictures under t...

Embodiment 3

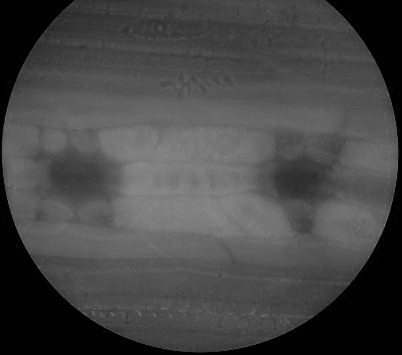

[0047] The sheet-making method of the pine needle leaf cross-section of the present embodiment comprises the following steps

[0048] (1) Pick off a piece of needle, put it on the surface of the laundry soap, put the laundry soap on the table, hold the single-sided blade in your right hand, and use the edge of the blade to cut the needle from the left side at the place where the needle needs to be cut To the right, cut a cross-cut slice;

[0049] (2) Use pointed tweezers to transfer it from the laundry soap to a petri dish filled with water, stir and clean it with a brush, and change the water for 3 times;

[0050] (3) Put the washed leaf cross section into 1% safranin aqueous solution and stain for 10 minutes; For a mixed solution of absolute ethanol and cedar oil (the volume ratio of absolute ethanol to cedar oil is 60:1), use absorbent paper to wipe off the white liquid that diffuses around; Cedar oil mixture, after repeating 6 times, add cedar oil dropwise on the leaf ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com