Polymer lithium ion battery

A lithium-ion battery and polymer technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as weak market competitiveness, lower cost performance of lithium-ion batteries, and increased battery manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

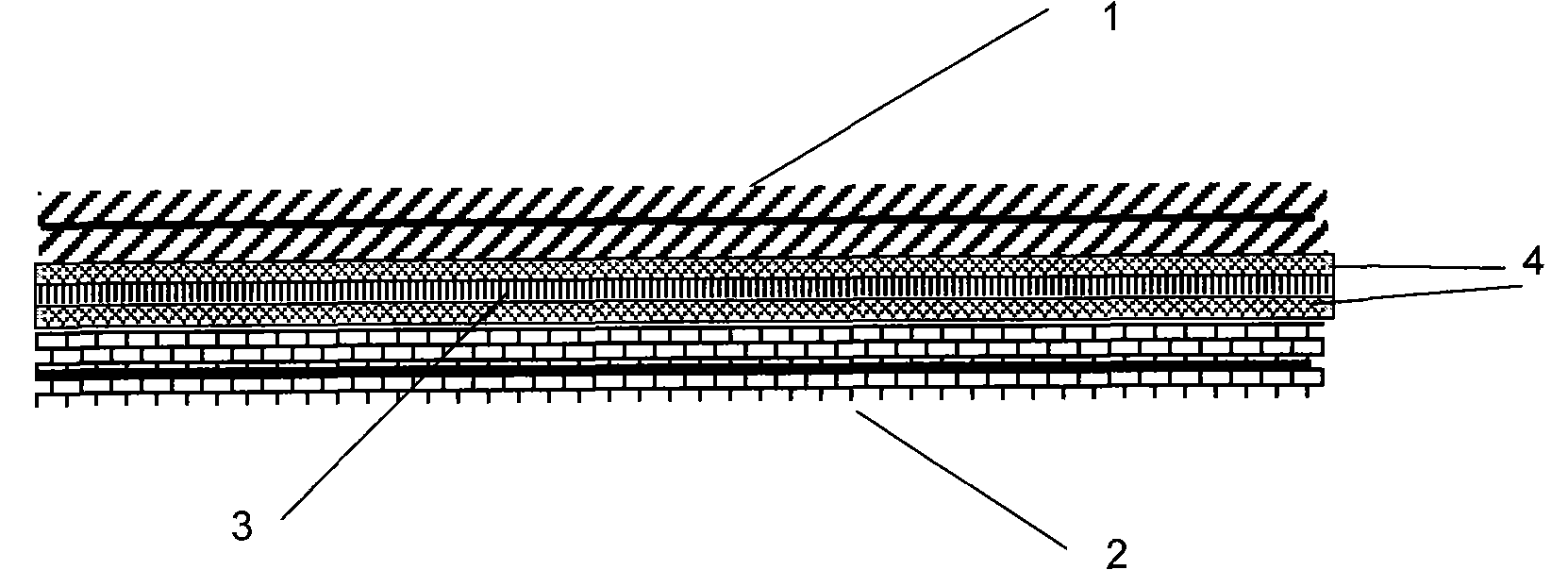

[0030] Such as figure 1 As shown, the first embodiment of the present invention includes a positive electrode 1 and a negative electrode 2, a separator 3 is arranged between the positive electrode 1 and the negative electrode 2, and there is a gel between the separator 3 and the positive electrode 1 and the negative electrode 2. Electrolyte layer 4.

[0031] Preferably, the negative electrode 2 is composed of a carbon material or a material capable of intercalating / deintercalating lithium as an active material, a current collector, a binder, a conductive agent, and the like.

[0032] Preferably, the positive electrode 1 is made of a transition zone metal oxide that contains lithium and can be used as a secondary lithium ion cathode active material as a basic raw material, and its chemical formula is: Li z m x N a C b o y , wherein M is a transition zone metal element, such as cobalt (Co), manganese (Mn), nickel (Ni) or other transition zone metal elements. N and C are me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com