Method for biologically improving oilseed residue

A technology of oil cakes and cakes, which is applied in the field of feed processing and microbial fermentation, can solve the problems of high loss of nutrients and dry matter, strict requirements on the fermentation environment, complex processing technology, etc., to achieve stable product quality and reduce equipment The effect of simple input and fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

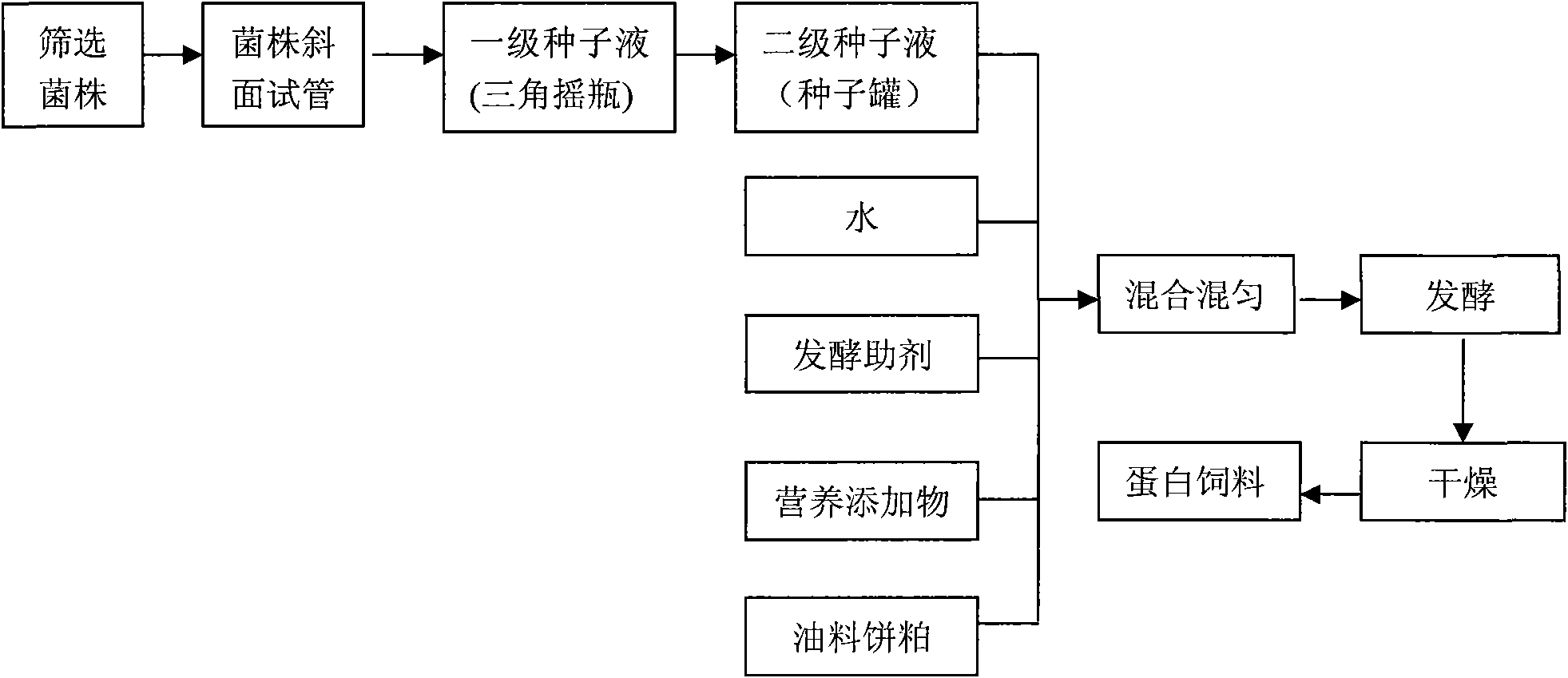

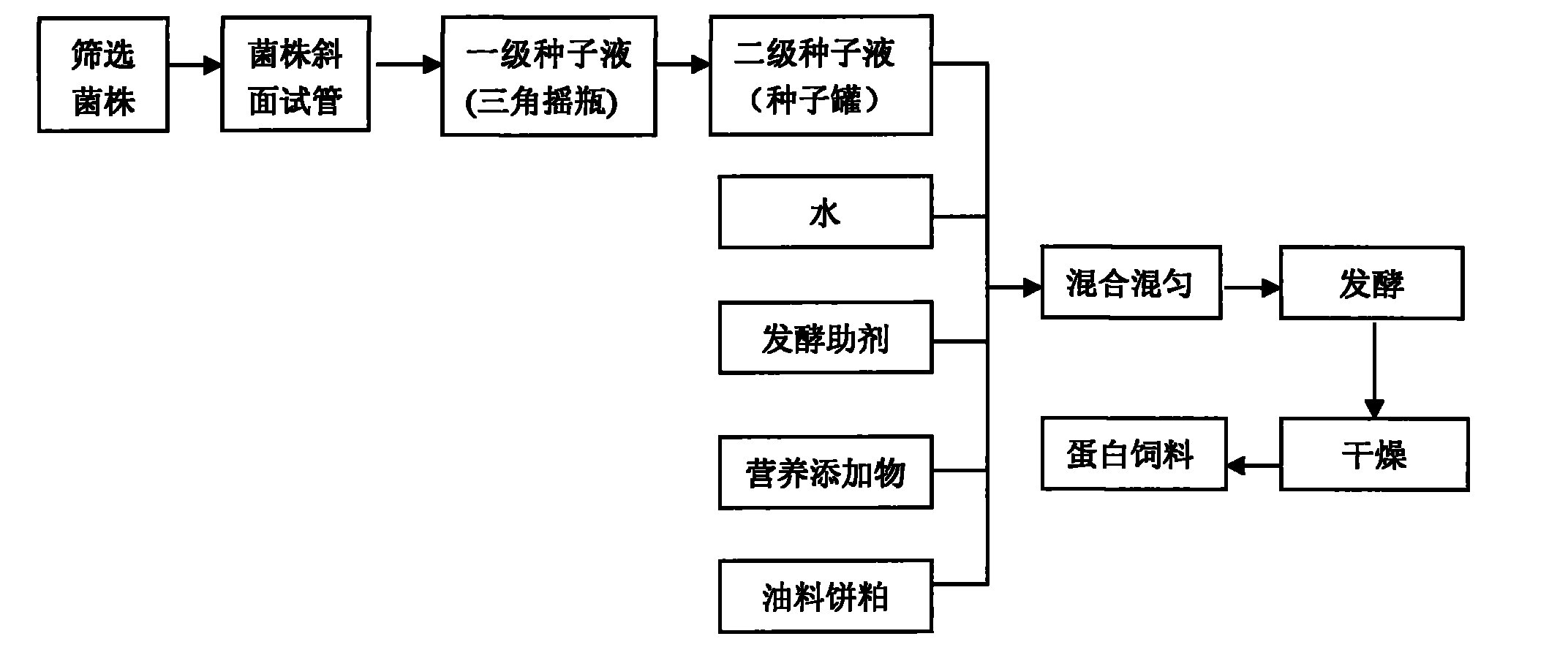

Method used

Image

Examples

Embodiment 1

[0027] Get rapeseed cake as main ingredient; Bacillus subtilis is passed through expansion cultivation, makes seed liquid, joins tap water by the inoculation amount of 1% of rapeseed cake weight, and the weight ratio of water and rapeseed cake is 2: 3. Based on the weight of the rapeseed cake, add 0.05% Aspergillus niger fermented product, 0.01% compound enzyme preparation, 0.15% nutrient, and then transfer the above mixture to a mixer to mix evenly with the rapeseed cake, The mixed base material is put into a fermentation tank at 25-35° C. for static fermentation for 72 hours, and the fermented base material is dried at 50° C. to obtain a protein feed product. The product has a strong fermented aroma. After measuring the contents of various anti-nutritional factors and nutritional components, it was found that the total content of isothiocyanate (OZT) and oxazolidinethione (ITC) was 1.92mg / g, crude The increase rate of protein content was 4.72%.

Embodiment 2

[0029] Rapeseed cake is taken as the main ingredient; Bacillus subtilis, Bacillus natto, and Saccharomyces cerevisiae are expanded and cultivated to make seed liquid, and the inoculation ratio of 1:1:1 by weight is 0.5% by weight of rapeseed cake. The amount of inoculum added to tap water, the weight ratio of water and rapeseed cake is 2:3, and based on the weight of rapeseed cake, add 0.05% Aspergillus niger fermentation product, 0.05% cellulase, 0.2% Nutrients, and then transfer the above mixture to a mixer to mix evenly with rapeseed cake, and put the mixed base material into a fermentation tank at 25-35°C for 72 hours of static fermentation. The fermented base material is dried at 50° C. to obtain a protein feed product. The product has a strong fermented aroma. After measuring the content of its various anti-nutritional factors and nutritional components, it was found that the total content of isothiocyanate (OZT) and oxazolidinethione (ITC) was 1.57 mg / g, and the increa...

Embodiment 3

[0031] Take dehulled cold-pressed rapeseed meal as the main material; Bacillus subtilis, Bacillus natto, Saccharomyces cerevisiae, and lactic acid bacteria are expanded and cultivated to make seed liquids respectively, and the weight ratio is 1:1:1:1. The inoculation amount of 1% of rapeseed meal weight is added to tap water, the weight ratio of water and dehulled cold-pressed rapeseed meal is 2: 3, and based on the weight of dehulled cold-pressed rapeseed meal, add 0.05% Aspergillus niger fermentation product, 0.01% plant Acid enzyme, 0.2% nutrient, and then the above mixture is transferred to a mixer and mixed evenly with dehulled cold-pressed rapeseed meal, and the mixed base material is put into a fermentation tank at 35-45 ° C for 72 hours of static fermentation. The fermented base material is dried at 50° C. to obtain a protein feed product. The product has a strong fermented aroma. After measuring the content of its various anti-nutritional factors and nutritional comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com