Method for refining low-odor polyether polyol

A technology of polyether polyol and refining method, which is applied in the direction of preparation of ether, medical preparations of non-active ingredients, pharmaceutical formulas, etc., can solve the problems of substances that cannot be used on a large scale and cannot remove odors, and achieve odor reduction and effective obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0027] In the following examples, 1000g of various crude polyether polyols (as described below) were added to a 3L stainless steel reaction kettle, heated to 70°C, 10g of pure water and 10g of hydrated magnesium silicate were added, and stirred for 30 minutes. Filter through a funnel, re-add the polyether polyol obtained after filtration into the reaction kettle, add 10g of pure water and 10g of diatomaceous earth, stir for 30 minutes, carry out vacuum dehydration for 1 hour, keep the temperature at 105±2°C, and then use a cloth Filter through a funnel to obtain refined polyether polyols.

[0028] The present invention is shown in Table 1 and Table 2 to the removing effect of the impurity in the polyether polyol used. Analysis is performed by chromatographic analysis of the liquid phase gas.

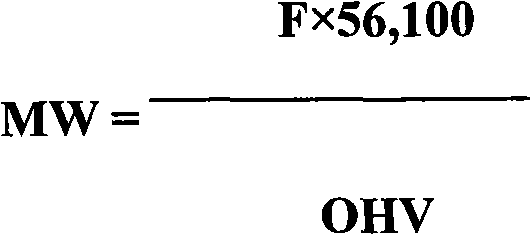

[0029] Polyether polyol 1: Ethylene oxide / propylene oxide polyether prepared from glycerol, which is branched, with an OH value of about 21, a molecular weight of 8000, KOH%=0.3%.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com