Method for testing melamine in raw milk and dairy products and preprocessing device

A technology for melamine and sample pretreatment, which is applied to measurement devices, material separation, and analysis of materials, etc., can solve problems such as inability to adapt to melamine detection pressure and low reliability, and achieve the effects of saving manpower and material resources, easy operation, and improving extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

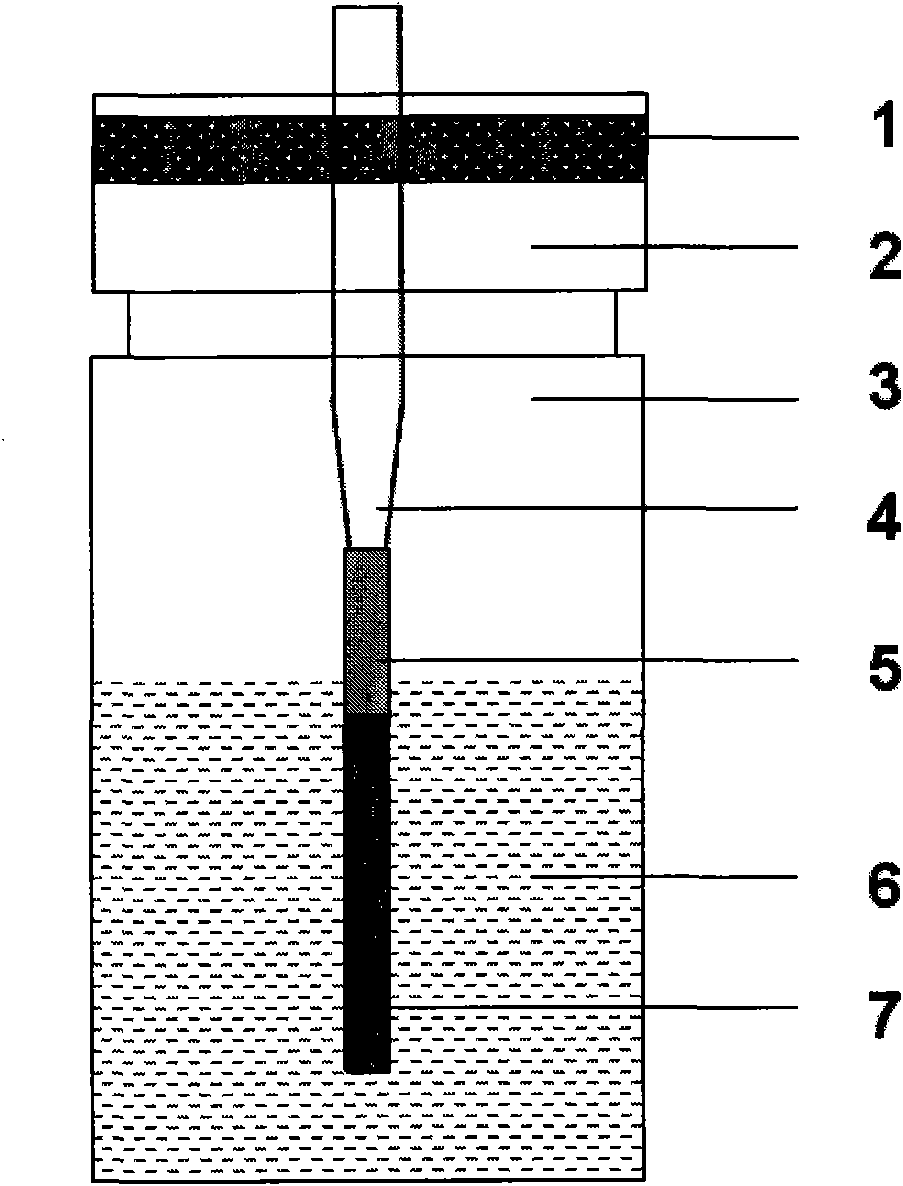

[0053] Preparation of sample pretreatment device:

[0054] Cut the hollow fiber membrane into 2.8 cm long sections, the material of the hollow fiber membrane is polyvinylidene fluoride fiber membrane, the wall thickness is 200 μm, the inner diameter is 1.2 mm, and the pore diameter is 0.2 μm; take a pipette tip of 5-10 μL as a plastic suction Cut off the thick end of the suction head, keep the pointed end, and cut it into 2.7 cm long sections. Soak the cut membrane and the suction head 4 in acetone for 20 minutes for ultrasonication, take it out and dry it; then glue the hollow fiber membrane and the tip of the suction head 4 tightly with glue, and close the other end of the hollow fiber membrane with flat tweezers until A transparent mark appears on the membrane, and the extraction tube is made;

[0055] Immerse the extraction tube in n-octanol (organic phase), and take it out after ultrasonication for 10 seconds, so that n-octanol is filled in the pore wall of the hollow fi...

Embodiment 2

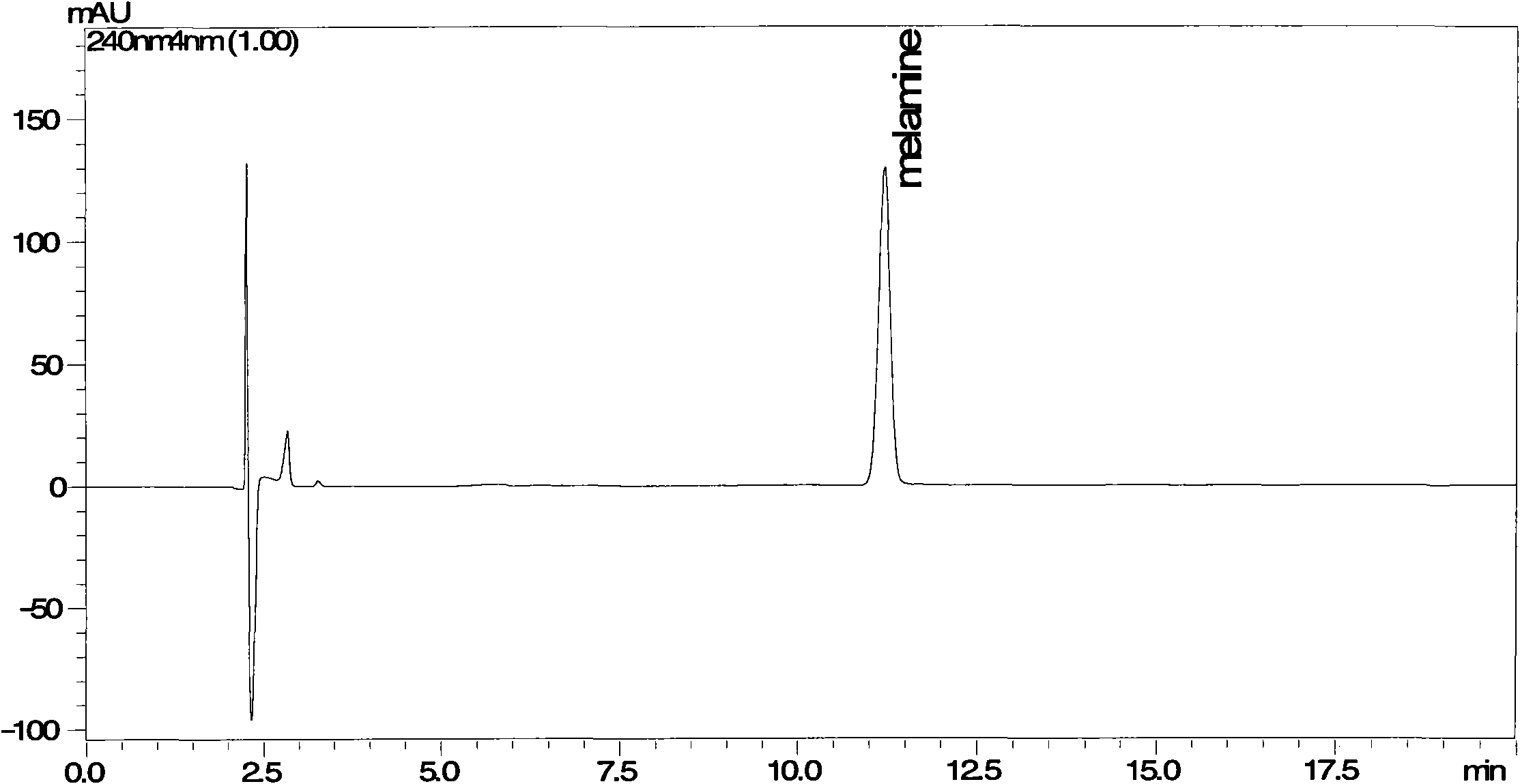

[0060] Blank test and standard recovery test of the detection method:

[0061] Prepare 1mg / mL melamine standard solution. Accurately measure 8 mL of liquid milk samples, add 8 μL of melamine standard solution (that is, the addition level is 1 μg / mL) to the spiked group, and not to the blank group, and process three samples in parallel in each group. Immerse the extraction tube in n-octanol and sonicate for 10 seconds, take it out and absorb the excess n-octanol with lens tissue. Insert the extraction tube into the sample bottle, draw 20 μL of distilled water (receiving phase) into the film with a micro-injector, and seal the tube opening with a parafilm. Put the extraction device into a shaker, shake and extract at a speed of 600r / min for 90min at room temperature. After extraction, absorb all the receiving phase, transfer to the sample injection vial, and wait for HPLC detection. Weigh 1.01g of sodium heptanesulfonate and 1.05g of citric acid, dissolve in water and set the...

Embodiment 3

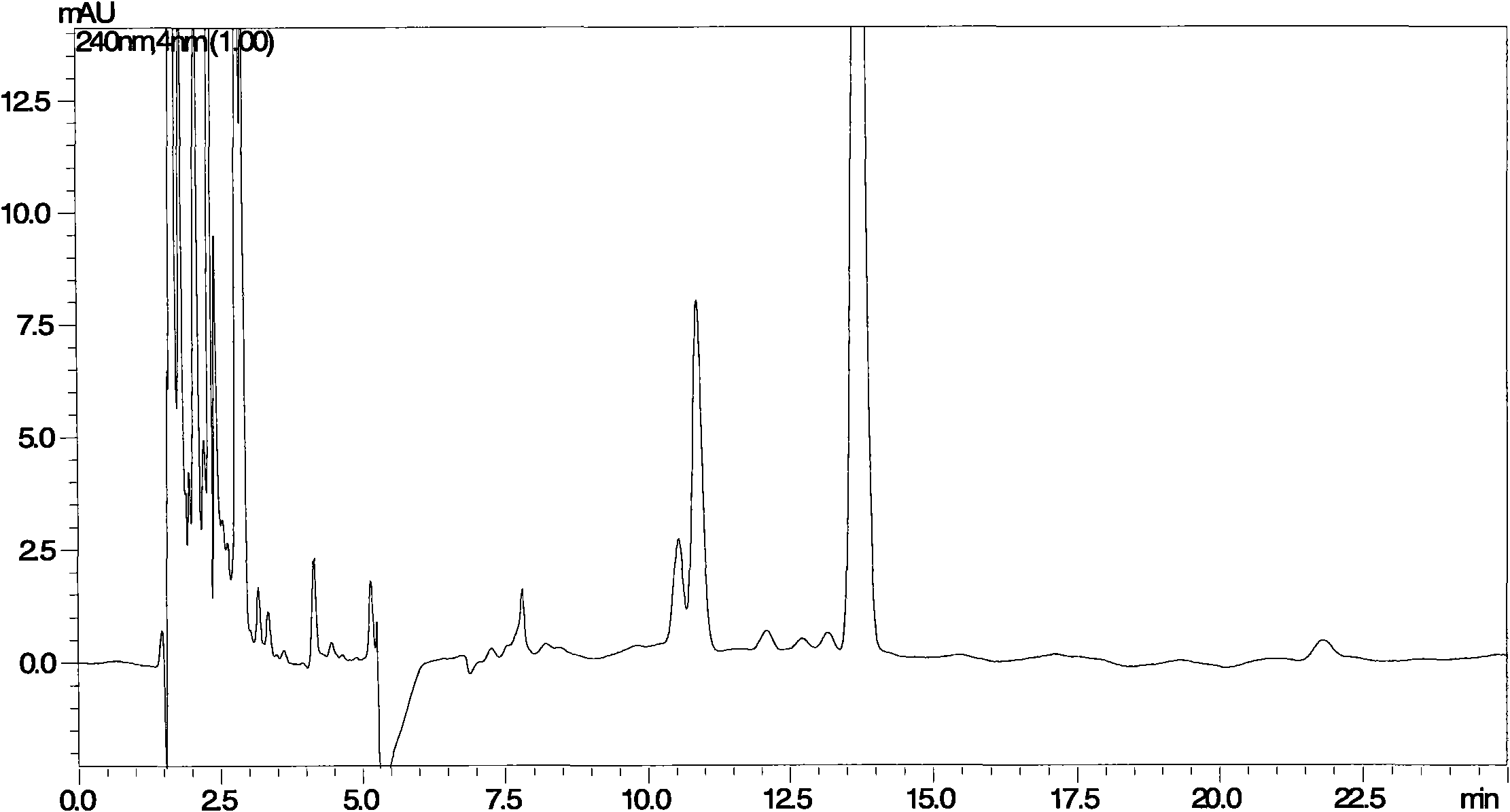

[0069] Test milk powder samples:

[0070] Prepare 1mg / mL melamine standard solution. A small packet (25g) of commercially available milk powder was dissolved in 200mL of warm water, and ultrasonicated for 5 minutes to prepare a milk sample. Accurately measure 8 mL of milk samples, add 16 μL of melamine standard solution (that is, the addition level is 2 μg / mL) to the spiked group, and not to the blank group, and process six samples in parallel in each group. Immerse the extraction tube in n-octanol and sonicate for 10 seconds, take it out and absorb the excess n-octanol with lens tissue. Insert the extraction tube into the sample bottle, draw 20 μL of distilled water (receiving phase) into the film with a micro-injector, and seal the tube opening with a parafilm. Put the extraction device into a shaker, shake and extract at a speed of 600r / min for 90min at room temperature. After extraction, absorb all the receiving phase, transfer to the sample injection vial, and wait for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com