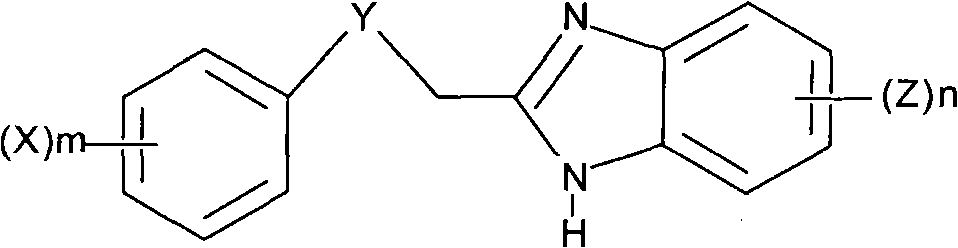

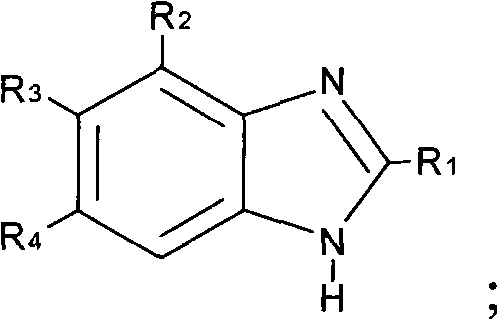

Imidazole derivative solution capable of being used as organic solderability preservative

A technology of imidazole derivatives and solder protection flux, which is applied in the field of organic solder protection, can solve problems such as the production process of printed circuit boards that cannot meet the excellence, and achieve the effect of excellent solderability and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

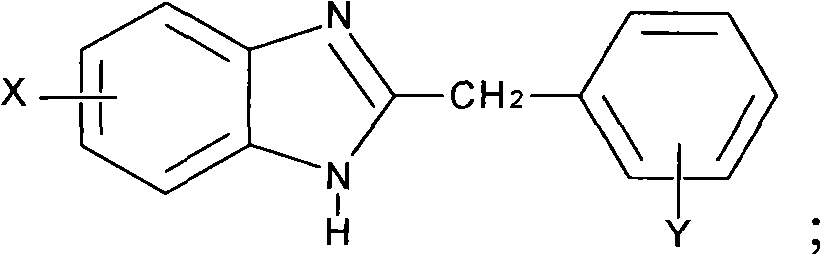

[0024] The present invention will be further described below in combination with specific embodiments.

[0025] The imidazole derivative solution that can be used as an organic soldering flux disclosed by the present invention is equipped with an organic soldering flux solution, which contains 5.0% [2-(4-chlorophenoxymethyl)]-1H-benzimidazole by weight, 20 % acetic acid, 0.2% heptanoic acid, 0.1% copper acetate. Adjust the temperature of the above-mentioned organic flux solution to 38° C., and adjust the pH value to 3.3.

[0026] A copper plate with a thickness of 0.3 mm and an area of 3 cm×7.5 cm was used as a test piece, and the test piece was treated with an organic solder preservation treatment with the above-mentioned organic flux solution, and then the test piece was subjected to solderability inspection.

[0027] The test piece must be polished, then acidic or alkaline cleaner to remove the surface oil, washed with sulfuric acid / hydrogen peroxide micro-etching soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com