Resin for high-flame-retardant phenol formaldehyde foam and production method thereof

A technology of phenolic foam and production method, which is applied in the directions of earthwork drilling, dust prevention and fire prevention, etc., can solve the problems of unsatisfactory flame retardancy of foam and easy precipitation of additives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

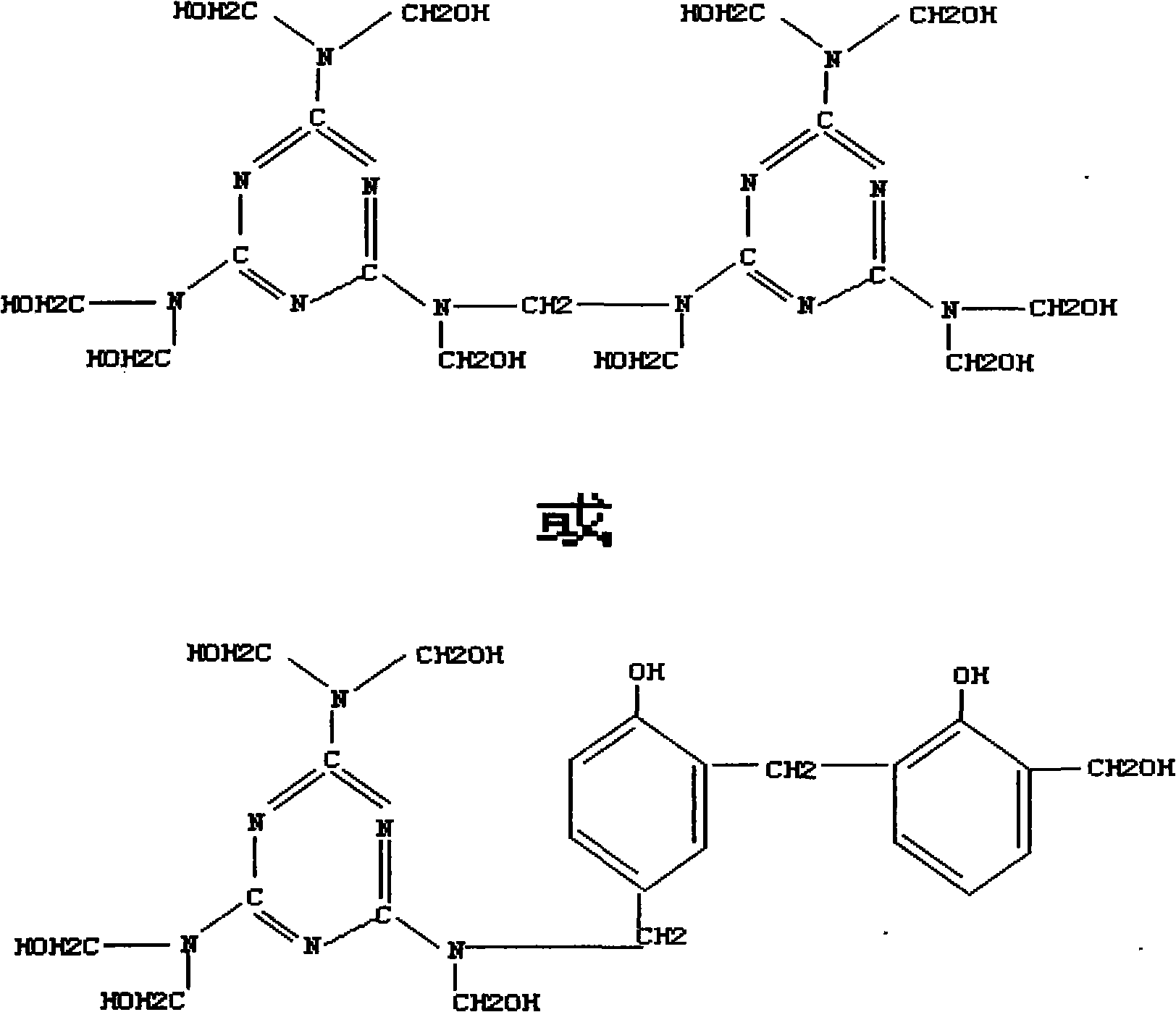

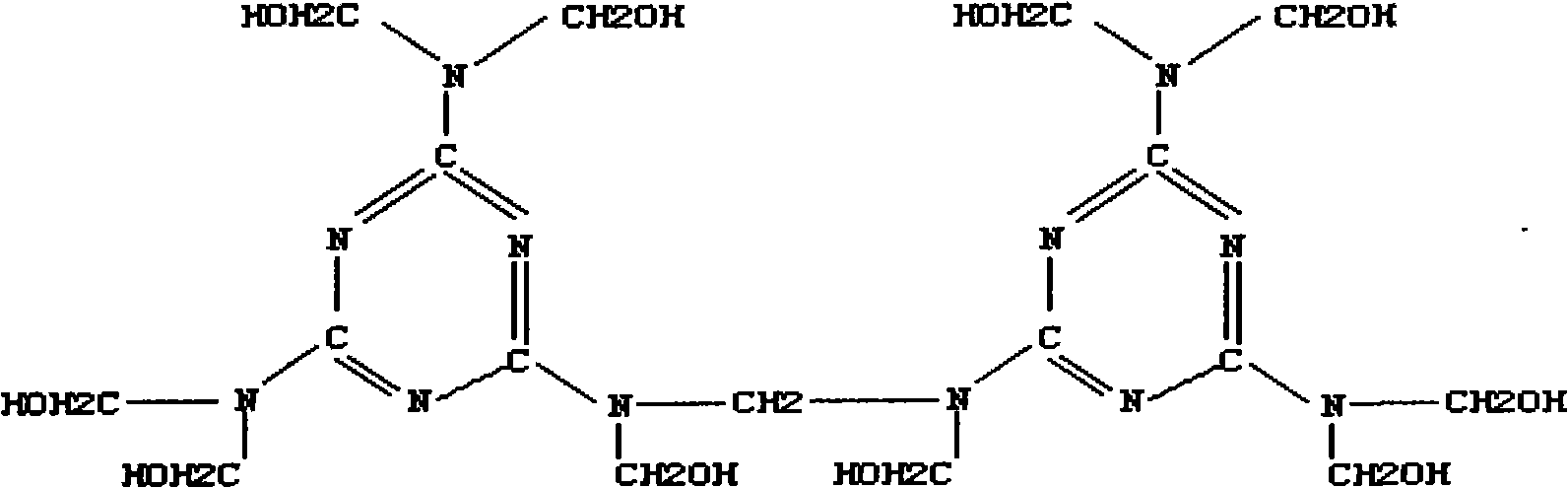

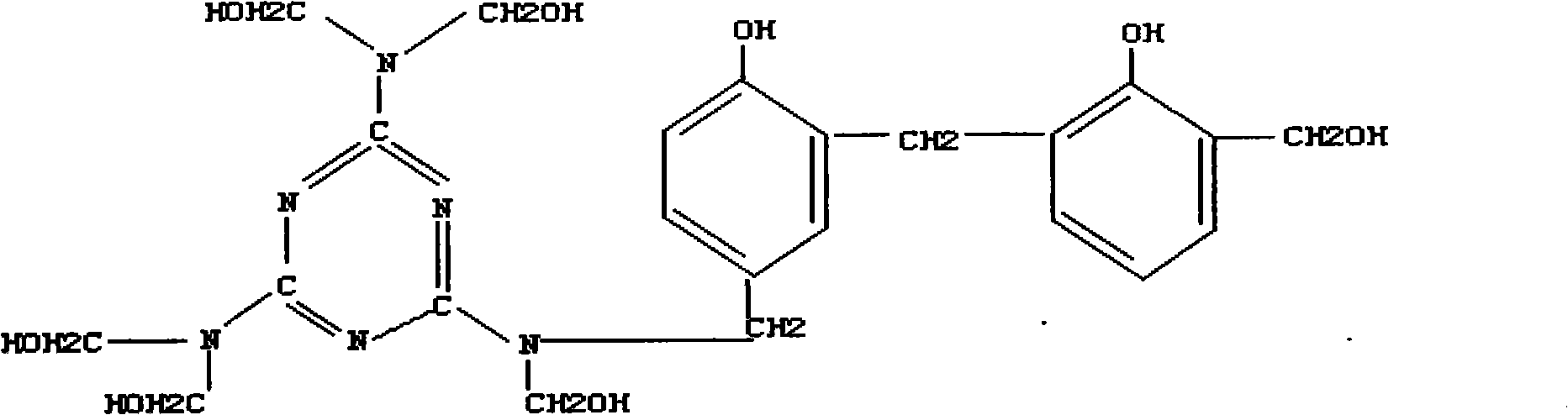

Method used

Image

Examples

example 1

[0045] Example 1 (continuous method)

[0046] Step 1: Take phenol: 282g (3mol), formaldehyde with a concentration of 37%: 292g (3.6mol), adjust the pH to 9.7-10.0 with 20% sodium hydroxide solution, heat up to 67°C-70°C for 4 hours , lower the temperature below 60°C, and generate ordinary phenolic foam resin.

[0047] The second step: add melamine: 2.25g, heat up to 92°C-95°C and react until the viscosity is 14.5 seconds-15 seconds (T-4 Tu 4 viscometer).

[0048] The third step: adjust the pH value to 6.0 to 8.5 with phosphoric acid, dehydrate 142g with a vacuum greater than -0.07Mpa, add polyethylene glycol: 9g, Tween 80: 6.75g, mix evenly, and finally obtain the present invention About 450g of high flame retardant phenolic foam resin.

example 2

[0049] Example two (continuous method)

[0050] Step 1: Take phenol: 282g (3mol), formaldehyde with a concentration of 37%: 413g (5.1mol), adjust the pH to 8.5-8.9 with 20% sodium hydroxide solution, heat up to 85°C-88°C for 2 hours , lower the temperature below 60°C, and generate ordinary phenolic foam resin.

[0051] The second step: add melamine: 5g, heat up to 60°C-65°C and react until the viscosity is 13-13.5 seconds (T-4 coated with 4 viscometer).

[0052] The third step: use lactic acid to adjust the pH value to 6.0~8.5, dehydrate 265g with a vacuum greater than -0.07Mpa negative pressure, add ethylene glycol: 40g, Tween 80: 25g, mix evenly, and finally obtain the high About 500g of resin for flame retardant phenolic foam.

example 3

[0053] Example three (continuous method)

[0054] Step 1: Take phenol: 282g (3mol), formaldehyde with a concentration of 37%: 510g (6.3mol), adjust the pH to 7.8-8.2 with 30% sodium hydroxide solution, heat up to 85°C-88°C for 1 hour , lower the temperature below 60°C, and generate ordinary phenolic foam resin.

[0055] The second step: add melamine: 16.2g, heat up to 75°C-78°C and react until the viscosity is 12.5 seconds-13.0 seconds (T-4 Tu 4 viscometer).

[0056] The third step: use lactic acid to adjust the pH value to 6.0-8.5, dehydrate 312g with a vacuum greater than -0.07Mpa, add ethylene glycol: 27g, Tween 80: 16.2g, mix evenly, and finally obtain the present invention About 540g of resin for high flame retardant phenolic foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com