Aqueous double-component polyurethane rubber coating, preparation thereof and use thereof

A polyurethane rubber, water-based two-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of flammability, explosion, incompatibility, etc., and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

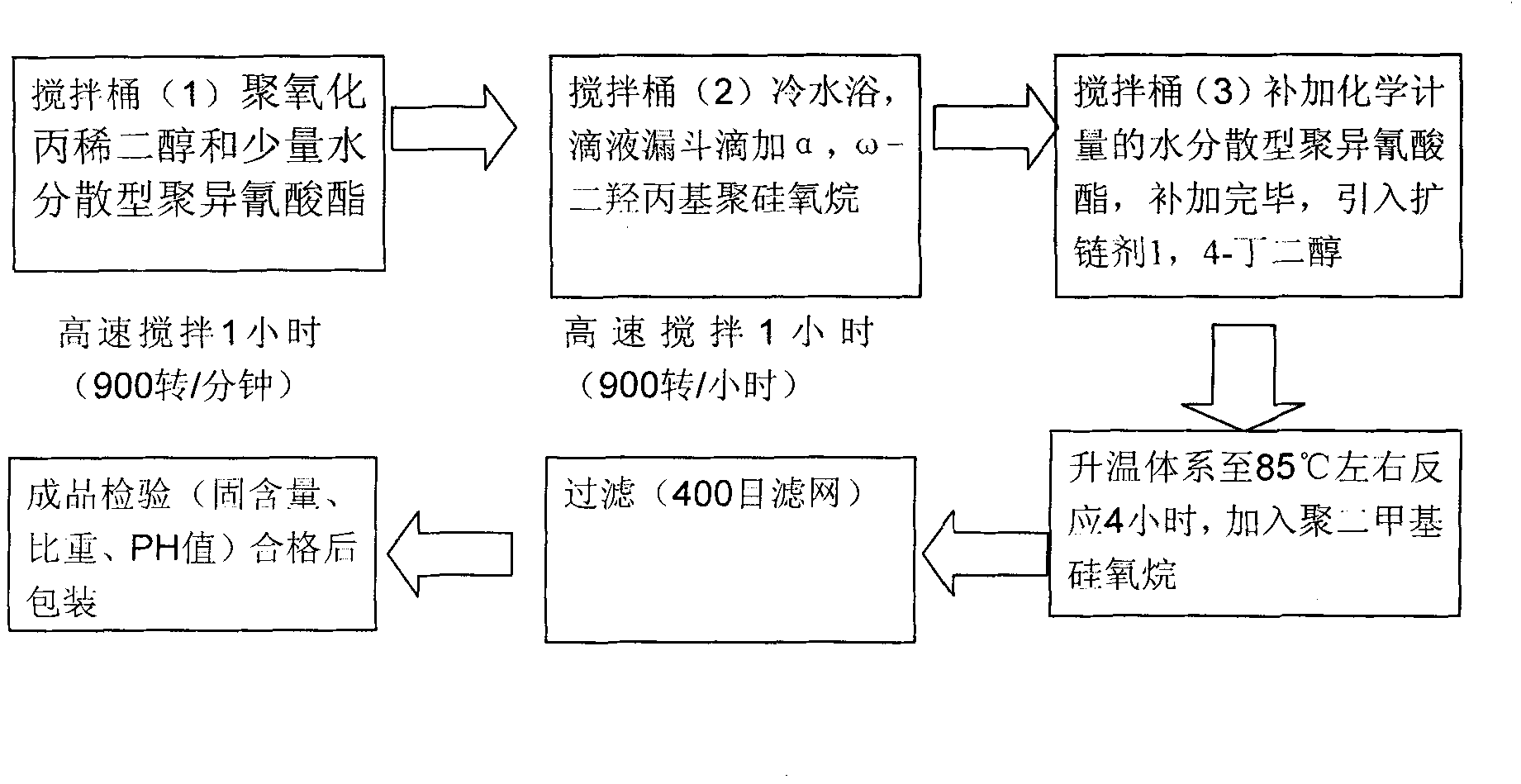

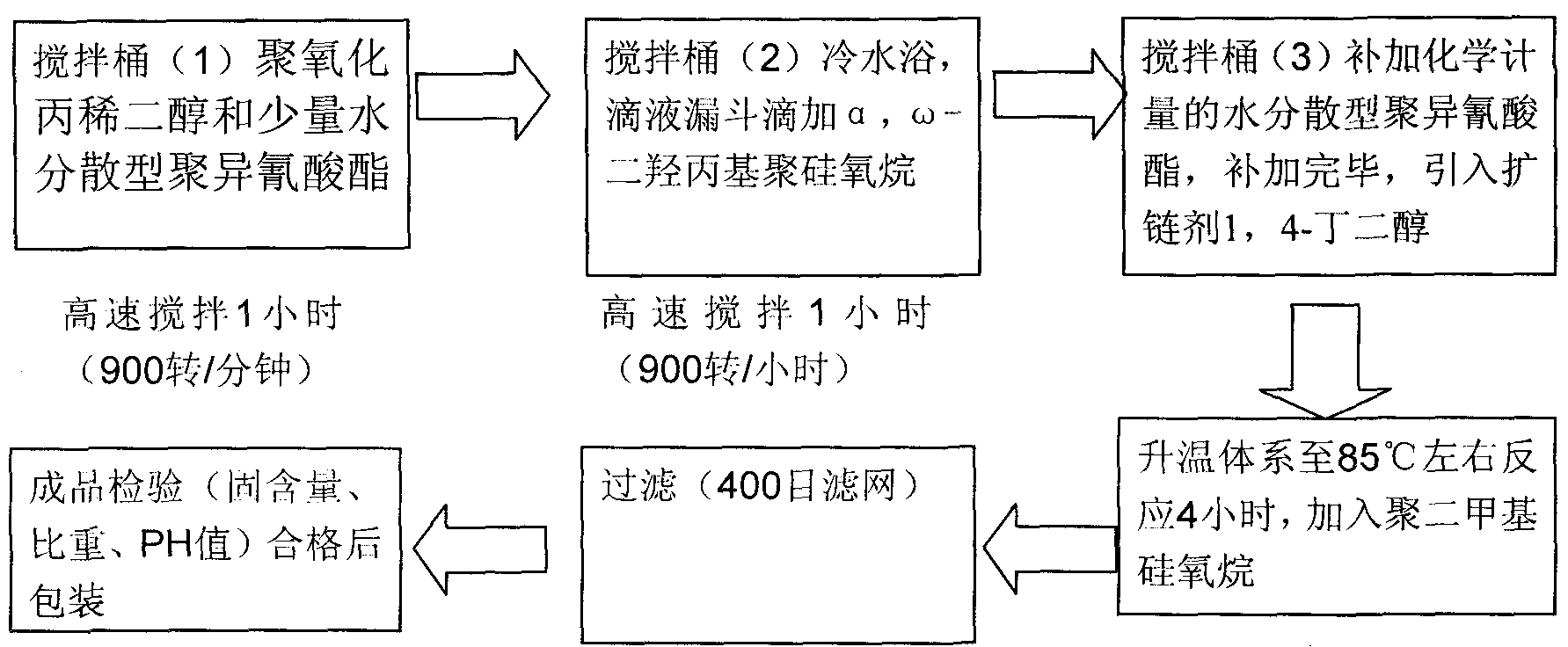

[0051] The preparation process of silicone copolymer modified polyurethane emulsion is as follows: figure 1 Shown:

[0052] 1) In a sealed reactor equipped with a high-speed disperser, high-purity nitrogen protection, and a thermometer, add 200 g of polyoxypropylene glycol and 40 g of water-dispersible polyisocyanate at -5 to 15°C, stir and mix evenly;

[0053] 2) Then under the condition of high-speed dispersion and stirring, 50g of α,ω-dihydroxypropyl polysiloxane was added dropwise through the dropping funnel, and the addition was completed in about 0.5h, and then 35g of chain extender 1,4-butyl was added. Diol, stir well;

[0054] 3) Add stoichiometric water-dispersed polyisocyanate to make n(NCO):n(OH)=2.5:1 (molar ratio) in the system;

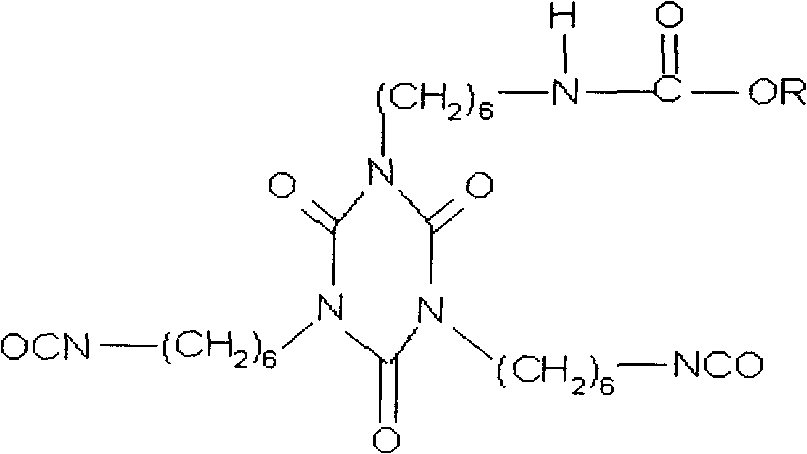

[0055] 4) Raise the system to 85~90℃ and react for 3~5 hours, add N-acyl methyl taurate sodium, alcohol ether sodium sulfate and Span-20 in weight ratio of 1:3:2 as the surface The active agent is uniformly mixed to prepare the organic silicon...

Embodiment 2

[0072] The modified waterborne polyurethane dispersion was prepared by the method of Example 1, except that the type of the surfactant was changed, and the other ratios and process conditions were the same. The appearance and film-forming stability of the coating were tested according to the GB9278-1988 and HG / T2458-1993 standards. The results are shown in Table 3:

[0073] Table 3 The effect of the types of surfactants on the coating film

[0074]

[0075]

Embodiment 3

[0077] The modified waterborne polyurethane dispersion was prepared by the method of Example 1, except that the content of the modified waterborne polyurethane dispersion in the first component was changed, and the other ratios and process conditions were the same. The appearance and film-forming stability of the coating were tested by GB9278-1988 and HG / T2458-1993 standards respectively. The results are shown in Table 4:

[0078] Table 4 The effect of modified waterborne polyurethane dispersion on the coating film

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of sliding friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap