Biomass gasification method and biomass gasification furnace

A technology of biomass and gasification furnace, which is applied in fixed bed gasification, manufacture of combustible gas, petroleum industry, etc. It can solve the problem of high tar content in combustible gas, achieve the effects of reducing tar content, lowering temperature and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

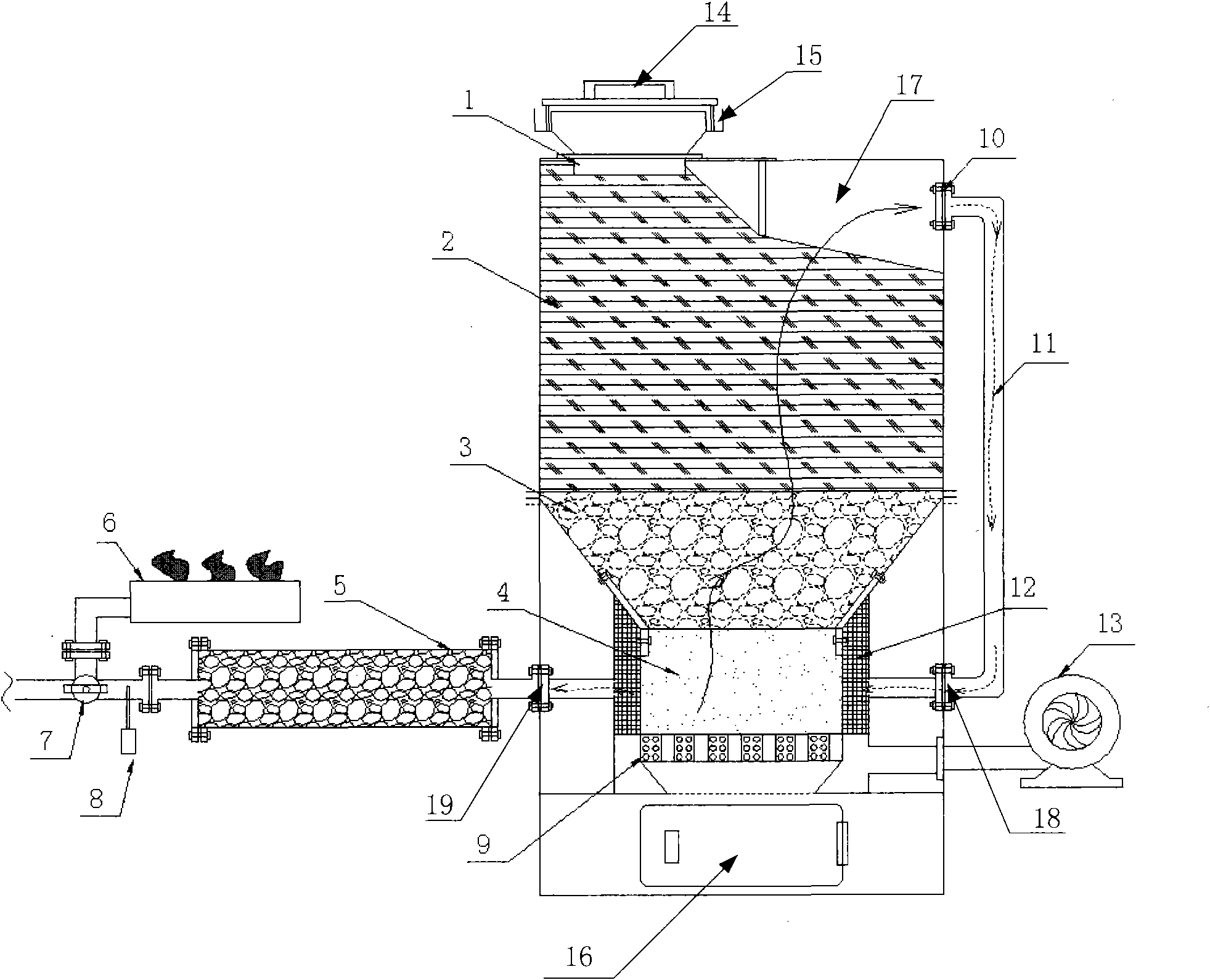

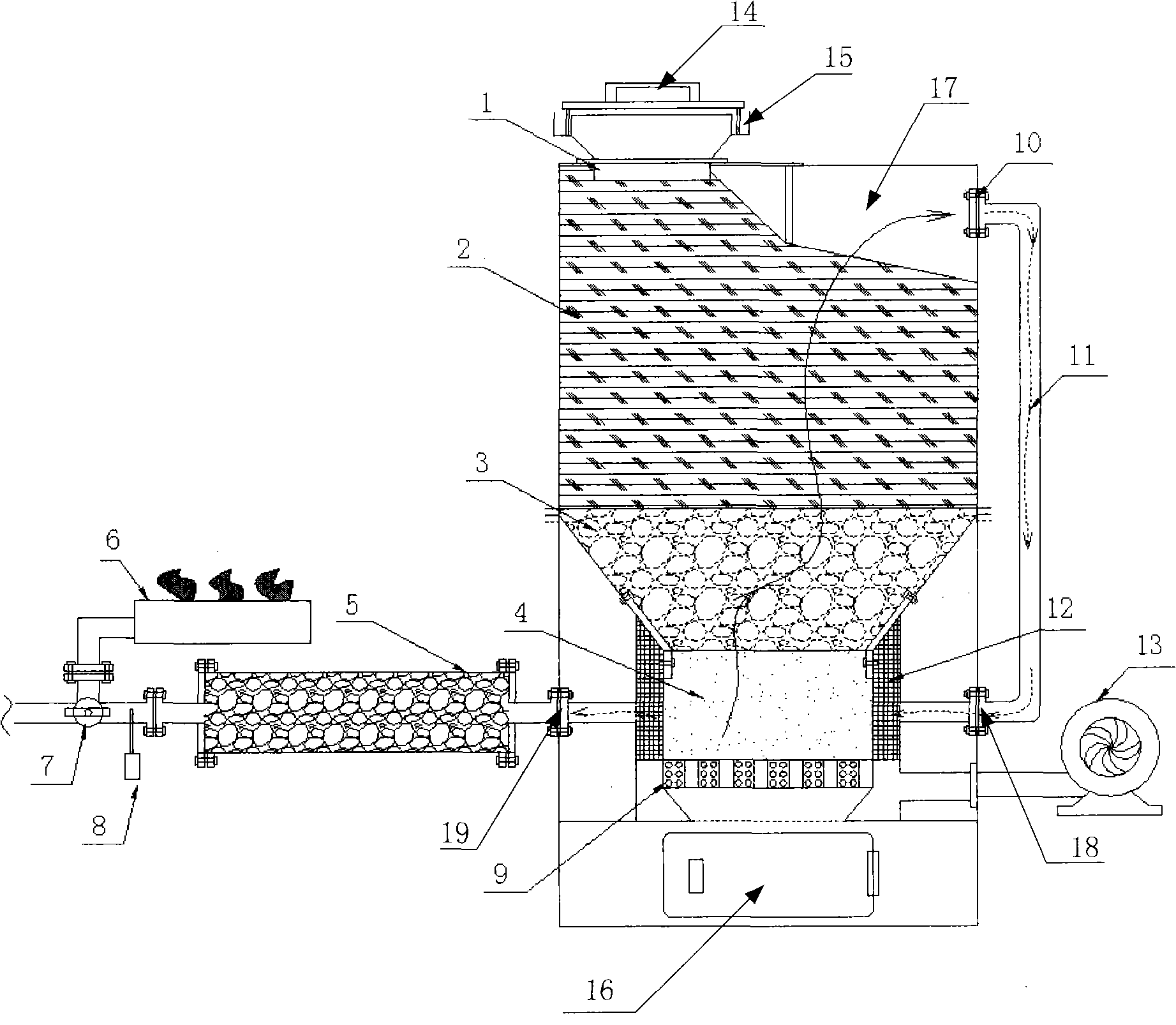

Image

Examples

Embodiment Construction

[0039] The invention provides a biomass gasification method, comprising:

[0040] Mix sea salt and limestone into the biomass to get a mixed feed;

[0041] Combusting the mixed material in an oxygen-deficient state to obtain a mixed gas;

[0042] Using limestone and sea salt as catalysts, the mixed gas is heated to 850°C-950°C to obtain combustible gas.

[0043] In the invention, biomass is used as raw material, limestone and sea salt are used as catalysts, and combustible gas is obtained by cracking under anoxic state.

[0044] According to the present invention, sea salt and limestone are firstly mixed into the biomass to obtain a mixed material. The present invention has no special limitation on the biomass, including but not limited to crop stalks, branches, dried weed husks, sawdust, and residues from pharmaceutical factories and sugar factories. The present invention preferably processes said biomass to a biomass having a length of less than 20 cm. The present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com