Tegafur/layered duplex metal hydroxide nanometer hybrid and preparation method thereof

A layered bimetallic and nano-hybrid technology is applied in the direction of pharmaceutical formulations, drug combinations, and medical preparations containing active ingredients. release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step a: 5.95g (0.020mol) Zn(NO 3 ) 2 ·6H 2 O and 3.75g (0.010mol) Al(NO 3 ) 3 9H 2 O was dissolved in 60ml of water and heated to 30°C.

[0041] Step b: Dissolve 0.50 g (0.0025 mol) of solid Tegafur in the mixed salt solution of step a.

[0042] Step c: Prepare a NaOH solution with a concentration of 2 mol / L.

[0043] Step d: Add the solution of step c to the solution of step b, keep stirring and control the pH to 9.7, the reaction temperature is 30°C, the stirring reaction time is 2 hours, then the obtained slurry is aged at 30°C for 18 hours, filtered, and washed with water until Neutral, peptized at 80°C for 24 hours to obtain Tegafur / LDHs nano-hybrids; dry to obtain powder products.

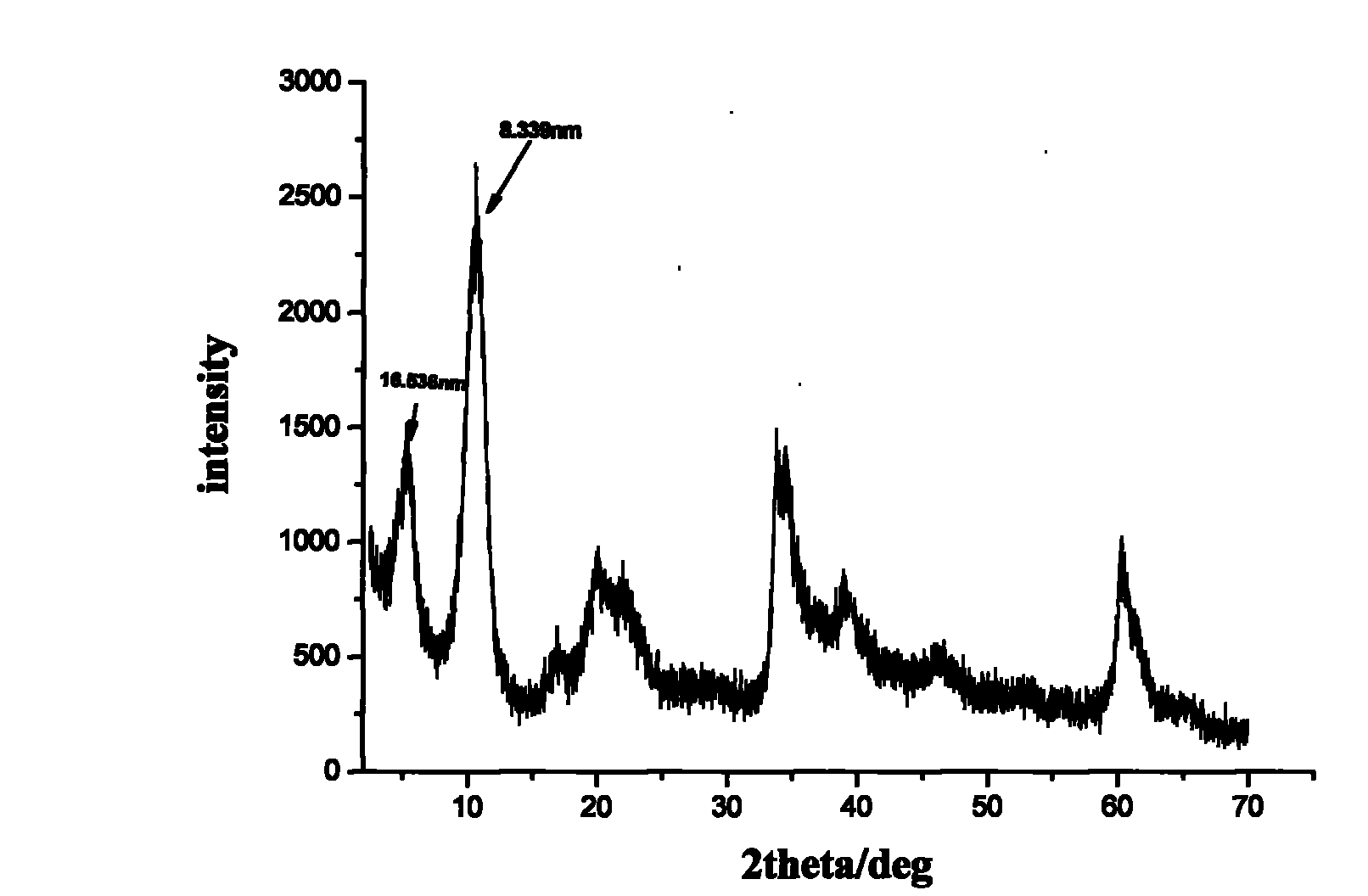

[0044] By XRD spectrum ( figure 1 ) shows that the Tegafur / LDHs nano-hybrid has a layered structure, and the interlayer spacing (d 003 ) shows that tegafur has been intercalated.

[0045] The sample was analyzed by ultraviolet spectrophotometry, and the content of tegafur was...

Embodiment 2

[0047] Step a: 1.59g (0.0053mol) Zn(NO 3 ) 2 ·6H 2 O and 1.00g (0.0026mol) Al(NO 3 ) 3 9H 2 O was dissolved in 20ml of water and heated to 60°C.

[0048] Step b: 0.66 g (0.0033 mol) of solid Tegafur was dissolved in the mixed salt solution of step a.

[0049] Step c: Prepare a NaOH solution with a concentration of 0.5 mol / L.

[0050] Step d: Add the solution of step c to the solution of step b, keep stirring and control the pH to 11.70, the reaction temperature is 60°C, the stirring reaction time is 1.5 hours, then the obtained slurry is aged at 60°C for 3 hours, filtered, and washed with water until Neutral, peptized at 80°C for 24 hours to obtain Tegafur / LDHs nano-hybrids; dry to obtain powder products.

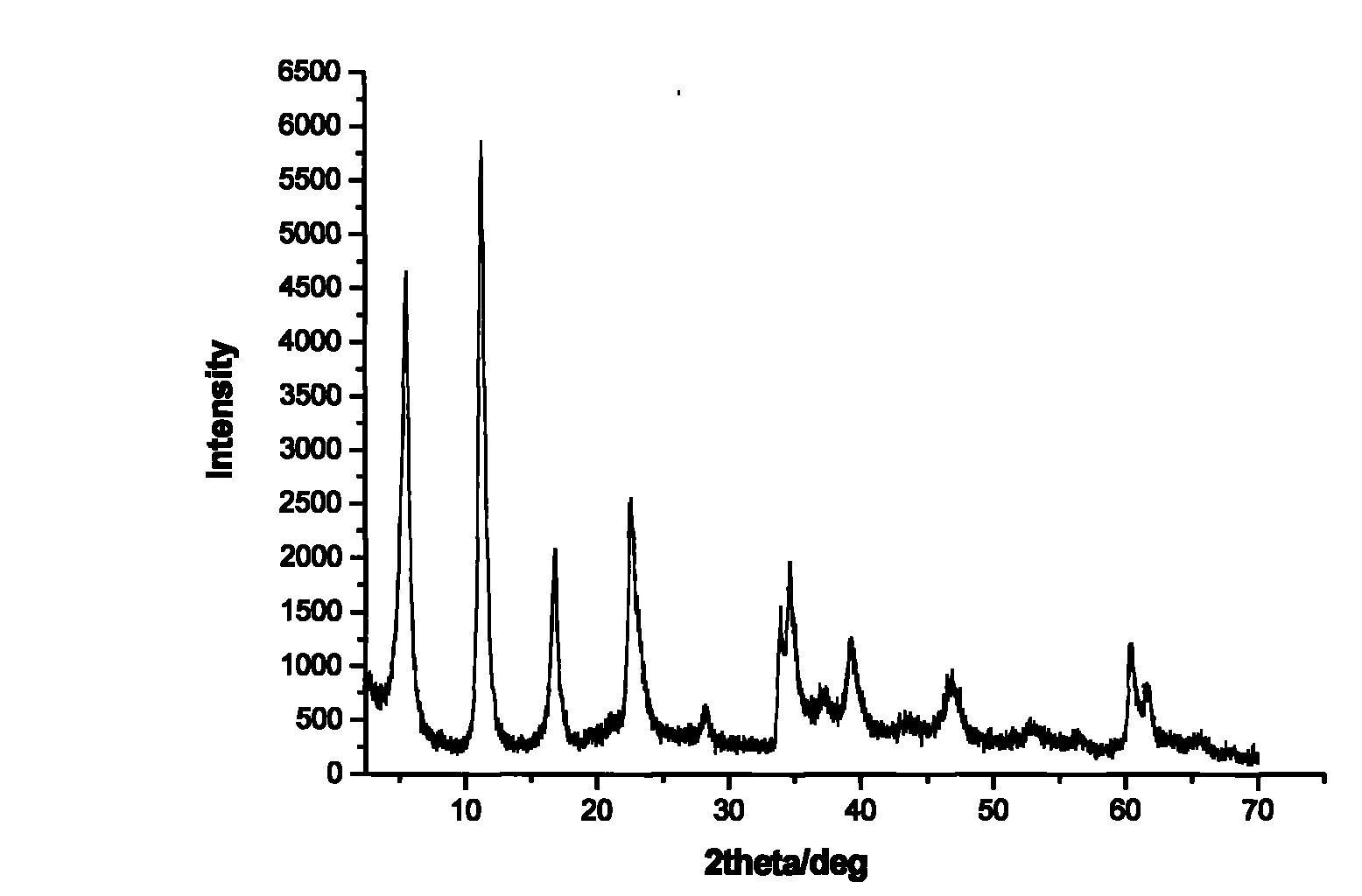

[0051] By XRD spectrum ( figure 2 ) shows that the Tegafur / LDHs nano-hybrid has a layered structure, and the interlayer distance d 003 It can be seen that tegafur has been intercalated.

[0052] The sample was analyzed by ultraviolet spectrophotometry, and the co...

Embodiment 3

[0054] Step a: 0.030mol of Ni(NO 3 ) 2 ·6H 2 O and 0.010mol of Al(NO 3 ) 3 9H 2 O was dissolved in 40ml of water and heated to 30°C.

[0055] Step b: Dissolve 0.50 g (0.010 mol) of solid Tegafur in the mixed salt solution of step a.

[0056] Step c: Prepare NH with a concentration of 1.0mol / L 4 OH solution.

[0057] Step d: Add the solution of step c to the solution of step b, keep stirring and control the pH to 10.06, the reaction temperature is 30°C, the stirring reaction time is 2 hours, then the obtained slurry is aged at 30°C for 15 hours, filtered, and washed with water until Neutral, peptized at 80°C for 24 hours to obtain Tegafur / LDHs nano-hybrids; dry to obtain powder products.

[0058] The sample was analyzed by ultraviolet spectrophotometry, and the content of tegafur was determined to be 10.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com