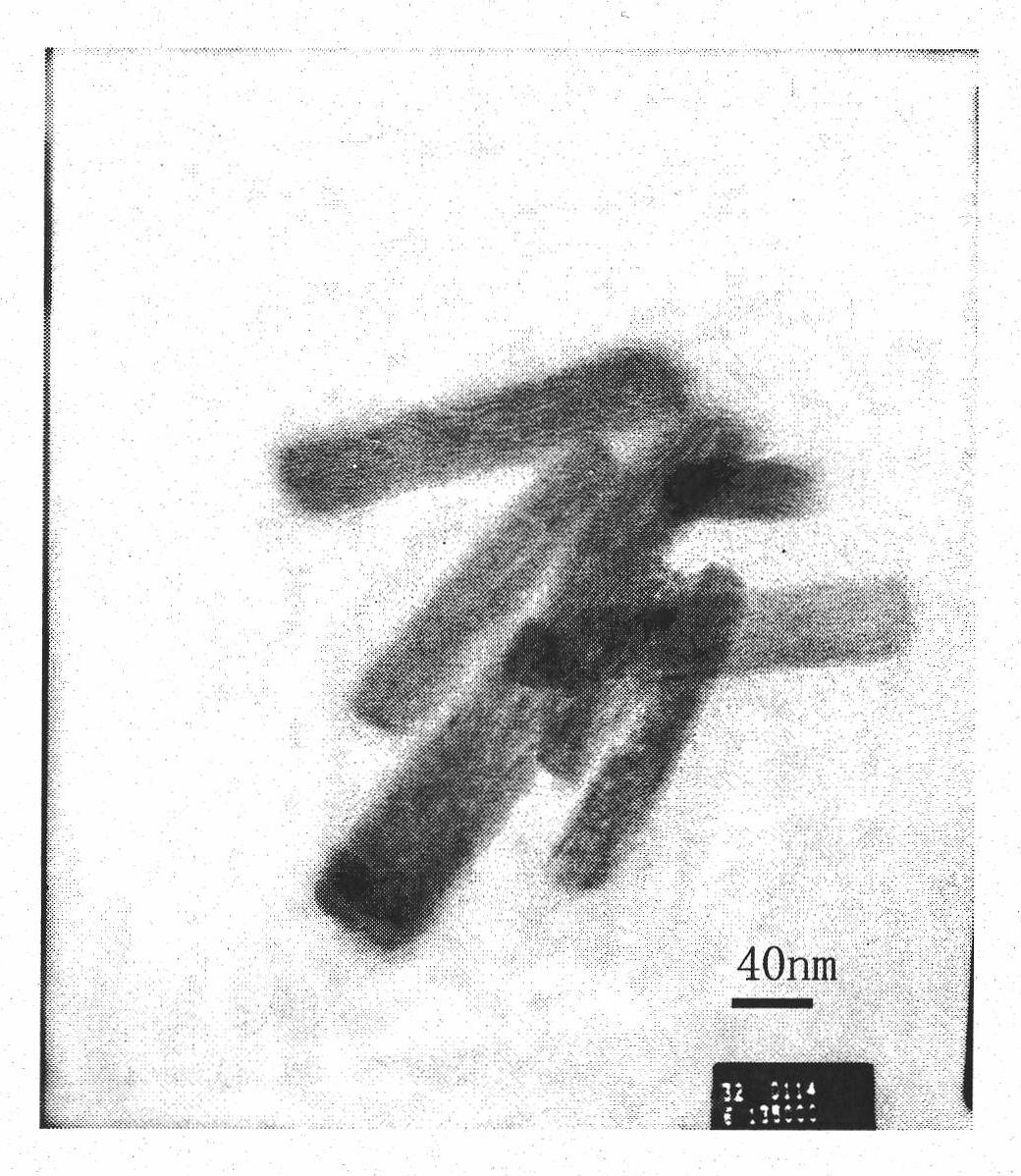

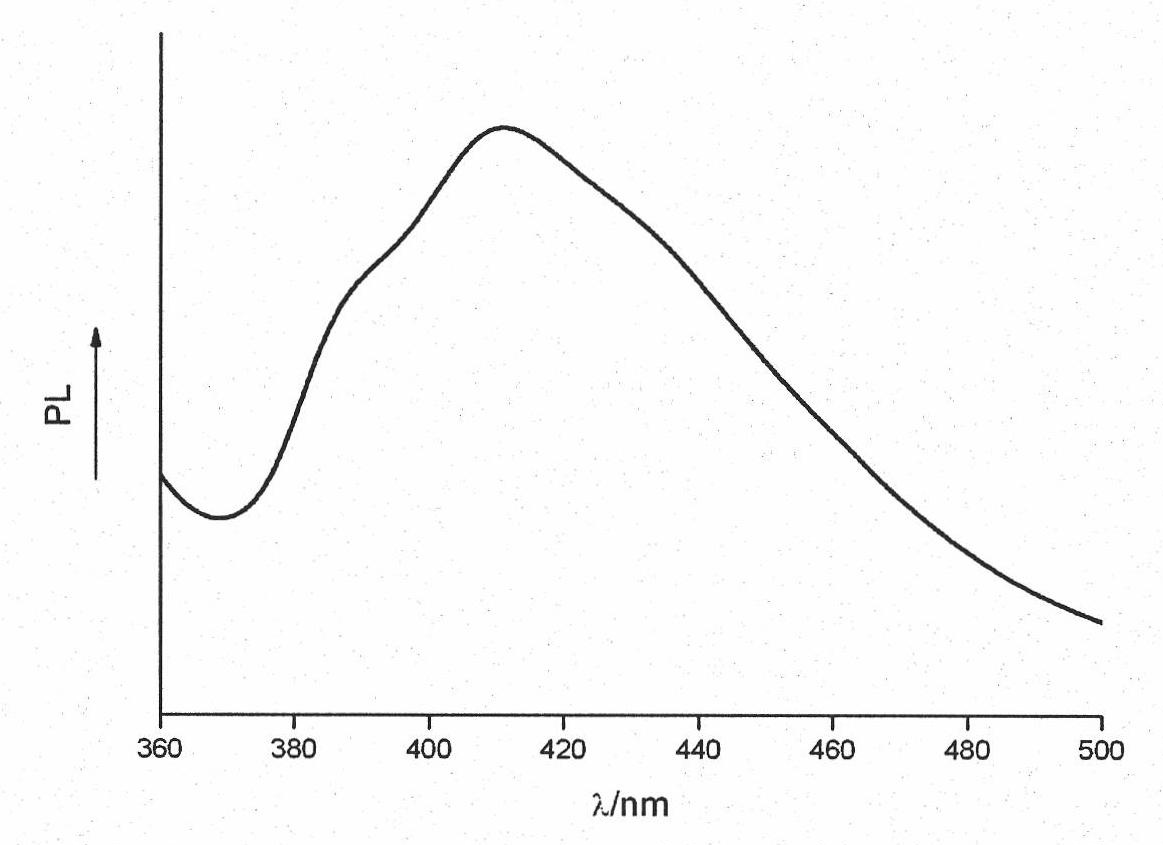

Method for synthesizing bar-shaped ZnSe fluorescence nanocrystalline

A technology of fluorescent nanocrystals and synthesis methods, applied in the field of nanomaterial synthesis, can solve the problems of long photodegradation time, nanocrystal surface defects, non-dense crystals, etc., and achieve high fluorescence quantum yield, toxicity and cost reduction, simplification The effect of the reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Synthesis of rod-shaped ZnSe nanocrystals:

[0049] 1. First, heat Se (0.048g, 0.6mmol), TOP (2*0.5g) in an oil bath at 40°C under the protection of nitrogen, and stir for one hour to obtain a Se precursor.

[0050] 2. Combine ODE (2g), ZincStearate (0.054g, 8.5*10 -5 mol), ODA (0.108g) was stirred and mixed under the protection of nitrogen to obtain the Zn precursor. The Zn precursor was "activated" by stirring at 50 °C for 3 hours.

[0051] 3. Octadecyl mercaptan (2.2925g, 8*10 -3 ) was added to the Zn precursor under the protection of nitrogen, and then stirred at 50°C for 1 hour to carry out "template" treatment.

[0052] 4. Continue to raise the temperature of the Zn precursor system to 305°C under the protection of nitrogen, and quickly inject the Se precursor into the Zn precursor while stirring. At this time, the temperature of the reaction system drops to 275°C, and the nanocrystals begin to grow. start the timer.

[0053] 5. After the nanocrystals start t...

Embodiment 2

[0056] 1. First, Se (0.048g, 0.6mmol), TOP (2*0.5g) was heated at 40°C under argon protection and ultrasonicated for half an hour to obtain the Se precursor.

[0057] 2. Combine ODE (2g), ZincStearate (0.0632g, 0.1*10 -3 mol), ODA (0.216g) was stirred and mixed under the protection of argon to obtain the Zn precursor. The Zn precursor was "activated" by ultrasonication at 70°C for 1 hour.

[0058] 3. Octadecyl mercaptan (2.2925g, 8*10 -3 ) was added to the Zn precursor under the protection of nitrogen, and then stirred at 50°C for 1 hour to carry out "template" treatment.

[0059] 4. Continue to raise the temperature of the Zn precursor system to 305°C under the protection of argon, and quickly inject the Se precursor into the Zn precursor while stirring. At this time, the temperature of the reaction system drops to 275°C, and the nanocrystals begin to grow. The reaction starts timing.

[0060] 5. After the nanocrystals start to grow, when the reaction time reaches 1 hour,...

Embodiment 3

[0063] 1. First, Se (0.048g, 0.6mmol) and TOP (2*0.5g) were heated at 40°C under nitrogen protection and ultrasonicated for half an hour to obtain the Se precursor.

[0064] 2. Combine ODE (2g), ZincStearate (0.054g, 8.5*10 -5 mol), the Zn precursor composed of hexadecylamine (2.16g) was fully ground at room temperature for 3 hours to realize its "activation" treatment.

[0065] 3. Octadecyl mercaptan (1.1462g, 4*10 -3 ) was added to the Zn precursor under the protection of nitrogen, and then stirred at 50°C for 1 hour to carry out "template" treatment.

[0066] 4. Under the protection of nitrogen, raise the temperature of the Zn precursor system to 315°C, and quickly inject the Se precursor into the Zn precursor while stirring. At this time, the temperature of the reaction system drops to 290°C, and the nanocrystals begin to grow, and the reaction start the timer.

[0067] 5. After the nanocrystals start to grow, when the reaction time reaches 1 hour and 30 minutes, stop h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com