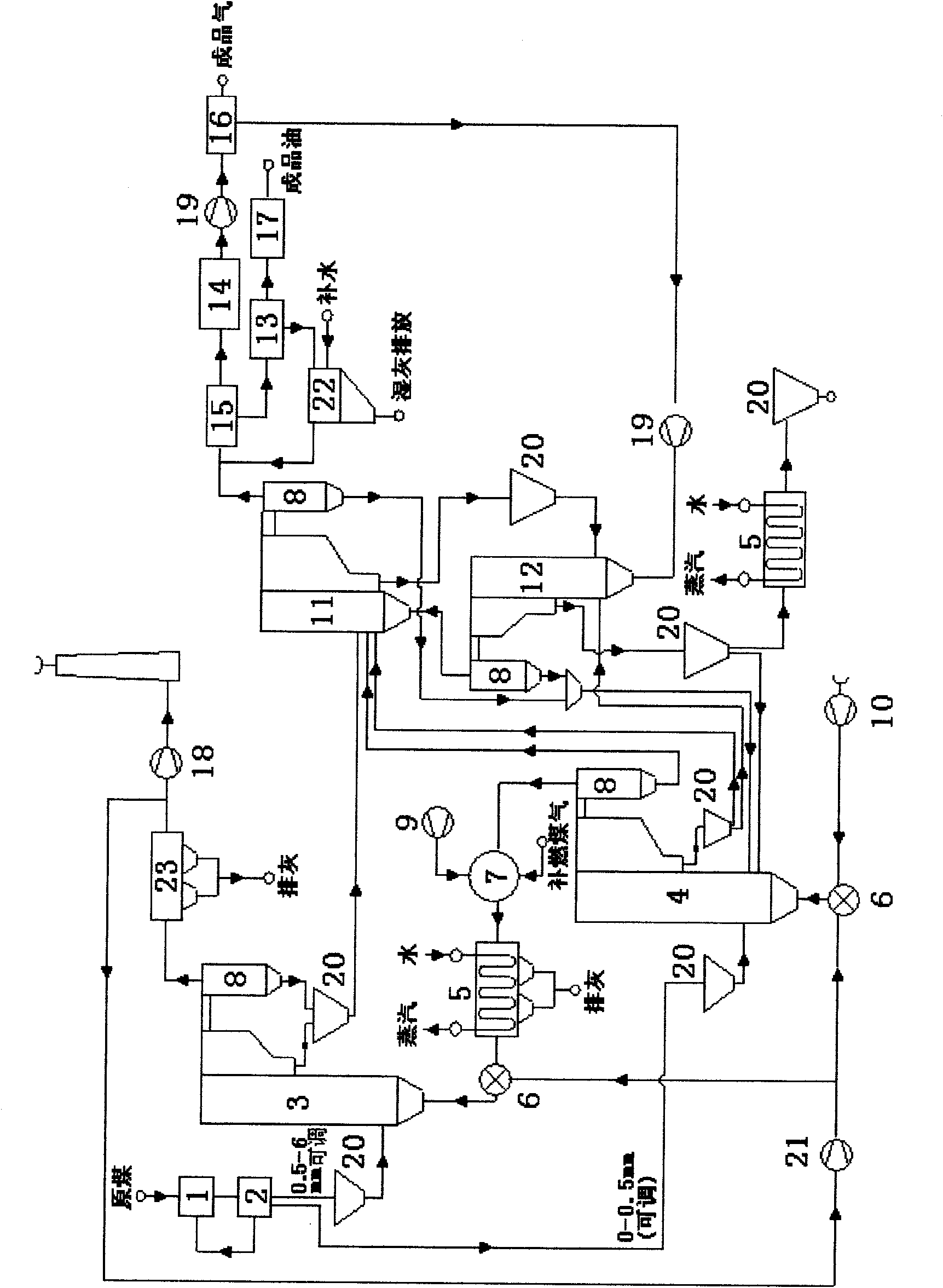

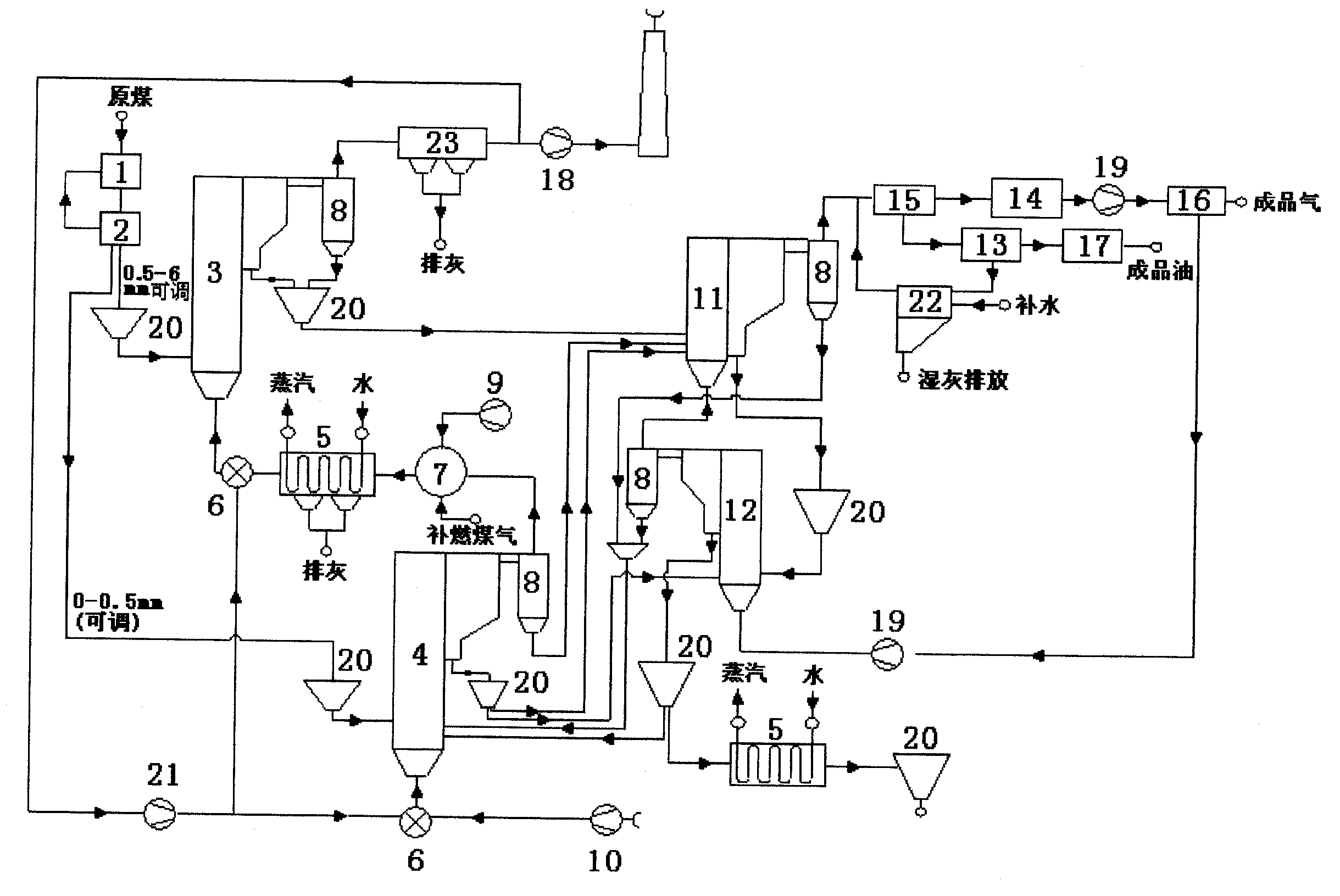

High-efficiency and quick lignite pyrolysis method

A technology for lignite and pyrolysis, applied in the field of coal chemical industry, can solve the problems of large water content of lignite, application limitation, low calorific value, etc., and achieve the effects of improved pyrolysis efficiency, wide application and promotion value, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Raw material is the lignite of Xiaolongtan Coal Mine in Yunnan Province, and industrial analysis data is: moisture content 35%, ash content 11% (dry basis), volatile content 49% (dry basis), present embodiment feeds intake 600kg, carries out fast through the method of the present invention Pyrolysis yields 183kg of semi-coke, 39kg of tar, 50 standard cubic meters of gas, and a comprehensive pyrolysis time of 20 minutes, which is 1 / 12 of the prior art pyrolysis time.

Embodiment 2

[0034] Raw material is the lignite of Xianfeng Coal Mine in Yunnan Province, and industrial analysis data is: moisture content 42%, ash content 13% (dry basis), volatile content 38% (dry basis), present embodiment feeds intake 600kg, carries out rapid heating through the inventive method Solution, get 213kg of semi-coke, 32kg of tar, 42 standard cubic meters of gas, and the comprehensive pyrolysis time is 24 minutes, which is 1 / 10 of the prior art pyrolysis time.

Embodiment 3

[0036] Raw material is the lignite of a coal mine in Zhaotong City, Yunnan Province, and the industrial analysis data is: industrial analysis is as follows: moisture content 48%, ash content 12% (dry basis), volatile content 45% (dry basis), the present embodiment feeds intake 600kg, through The method of the present invention carries out rapid pyrolysis to obtain 152 kg of semi-coke, 34 kg of tar, 40 standard cubic meters of gas, and a comprehensive pyrolysis time of 30 minutes, which is 1 / 8 of the prior art pyrolysis time.

[0037] Features of the present invention:

[0038] 1. Rationally utilize lignite resources to realize co-production of coke, gas and oil, use low-value lignite to produce high value-added oil, gas and coke, and rationally utilize the volatile matter in lignite.

[0039] 2. Effective use of flue gas waste heat to remove moisture from lignite, which solves the problem of high moisture content and difficult utilization of lignite.

[0040] 3. Make full use o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com