Method for manufacturing alternating current electrophoresis directionally assembled carbon nanotube array sensing device

A technology for carbon nanotube arrays and sensor devices, applied in electrophoretic plating, electrolytic coatings, gaseous chemical plating, etc., can solve the problems of low sensitivity and selectivity of carbon nanotube arrays, and achieve improved sensitivity and detection selectivity, The effect of high-sensitivity detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

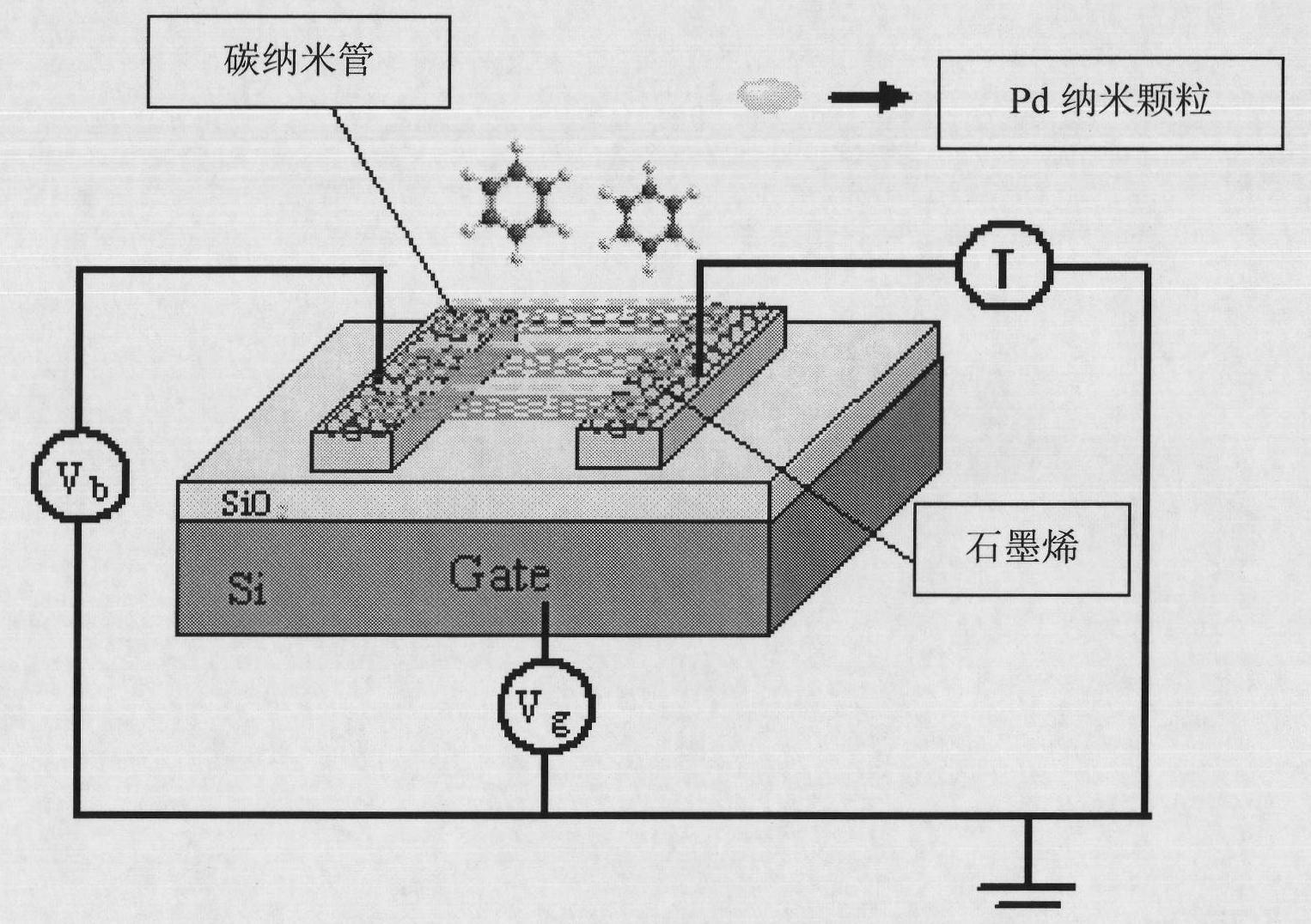

[0024] In recent years, chemical vapor deposition has made great progress in the preparation of graphene films. The present invention utilizes metal film electrodes as catalysts to grow graphene films on them as electrodes for AC electrophoresis to achieve directional assembly of carbon nanotube arrays, because Both carbon nanotubes and graphene are carbon materials with similar work functions. From the perspective of energy, they will not form contact with each other, which reduces the resistance between electrodes and carbon nanotubes, making them high-performance sensing devices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com