Method for preparing refined salt without antitackiness agent

A technology of refined salt and anti-caking agent, which is applied in the field of alkali metals, can solve problems such as insecurity, and achieve the effects of less impurities, good anti-caking and good anti-caking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

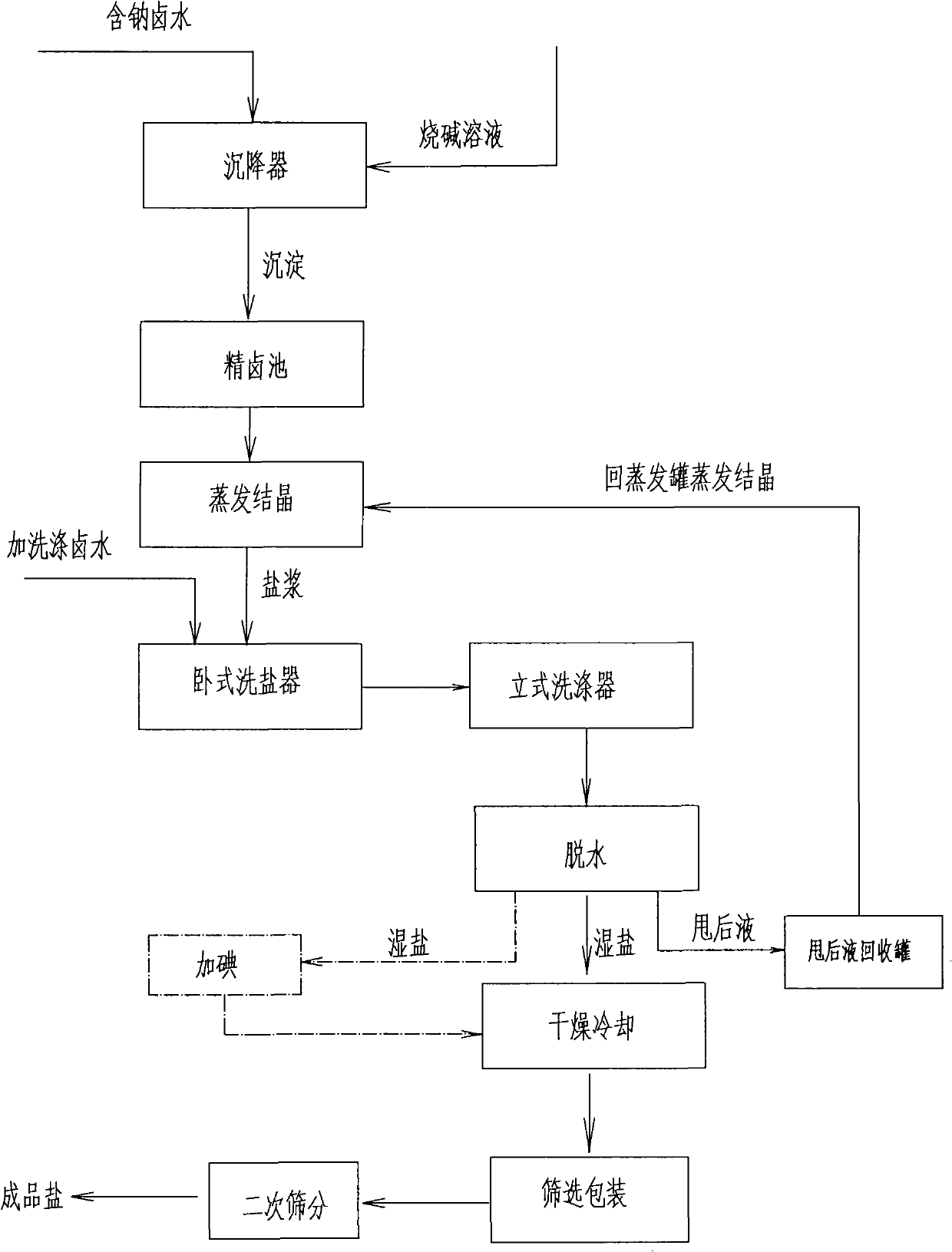

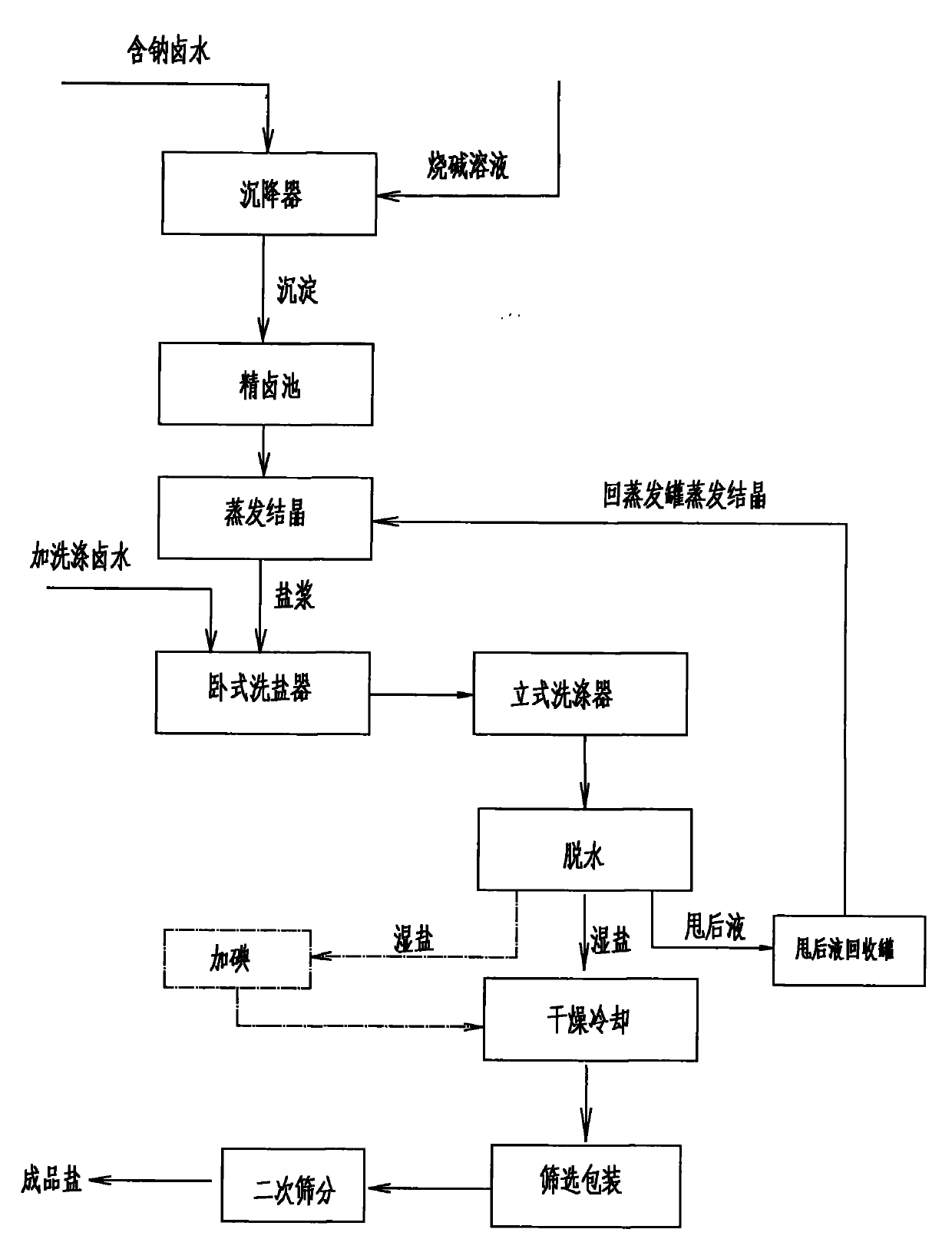

[0015] Embodiment one. refer to figure 1 . A preparation method of refined salt without anti-caking agent: input the brine with a NaCl content of 300 g / L into the inclined plate settler, and add caustic soda solution with a mass percentage concentration of 30% to adjust the pH value to 8 , and then the brine is input into the sedimentation tank, and after precipitation, it enters the original brine pool to obtain clean brine; through the feeding pump, the clean brine is pumped into the four-effect internal heating evaporation tank for evaporation, and the steam pressure is controlled at 0.3MPa. After concentrating and crystallizing, discharge the salt to obtain salt slurry, the solid-to-liquid ratio of the salt slurry is 3:7; the salt slurry discharged from each effect evaporation tank is first washed in a horizontal stirring tank, and Mg 2+ The brine with a content of 0.4 g / liter dissolves the sodium sulfate in the salt slurry, and then pumps it into a vertical salt washer ...

Embodiment 2

[0016] Embodiment two. refer to figure 1 . A preparation method of refined salt without anti-caking agent: after the brine with a NaCl content of 305 g / L is taken out, it is input into an inclined plate settler, and a caustic soda solution with a mass percentage concentration of 28% is added to adjust the pH value to 9 , and then the brine is input into the sedimentation tank, and after precipitation, it enters the original brine pool to obtain clean brine; through the feeding pump, the clean brine is pumped into the four-effect internal heating evaporation tank for evaporation, and the steam pressure is controlled at 0.25MPa. After concentrating and crystallizing, discharge the salt to obtain salt slurry, the solid-to-liquid ratio of the salt slurry is 3:7; the salt slurry discharged from each effect evaporation tank is first washed in a horizontal stirring tank, and Mg 2+ The brine with a content of 0.5 g / l dissolves the sodium sulfate in the salt slurry, and then pumps it...

Embodiment 3

[0017] Embodiment three. refer to figure 1 . A preparation method of refined salt without anti-caking agent: after the brine with a NaCl content of 305 g / L is taken out, it is input into an inclined plate settler, and a caustic soda solution with a mass percentage concentration of 28% is added to adjust the pH value to 9 , and then the brine is input into the sedimentation tank, and after precipitation, it enters the original brine pool to obtain clean brine; through the feeding pump, the clean brine is pumped into the four-effect internal heating evaporation tank for evaporation, and the steam pressure is controlled at 0.25MPa. After concentrating and crystallizing, discharge the salt to obtain salt slurry, the solid-to-liquid ratio of the salt slurry is 3:7; the salt slurry discharged from each effect evaporation tank is first washed in a horizontal stirring tank, and Mg 2+ The brine with a content of 0.5 g / l dissolves the sodium sulfate in the salt slurry, and then pumps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com