Novel preparation method for sulfated chitosan

A technology of chitosan and chitosan, which is applied in the field of preparing sulfated chitosan, can solve the problems of difficult control of the operation process, reagents affecting the application, adverse effects of the application, etc., and achieves low production cost, good immune regulation effect, Sulfate content safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

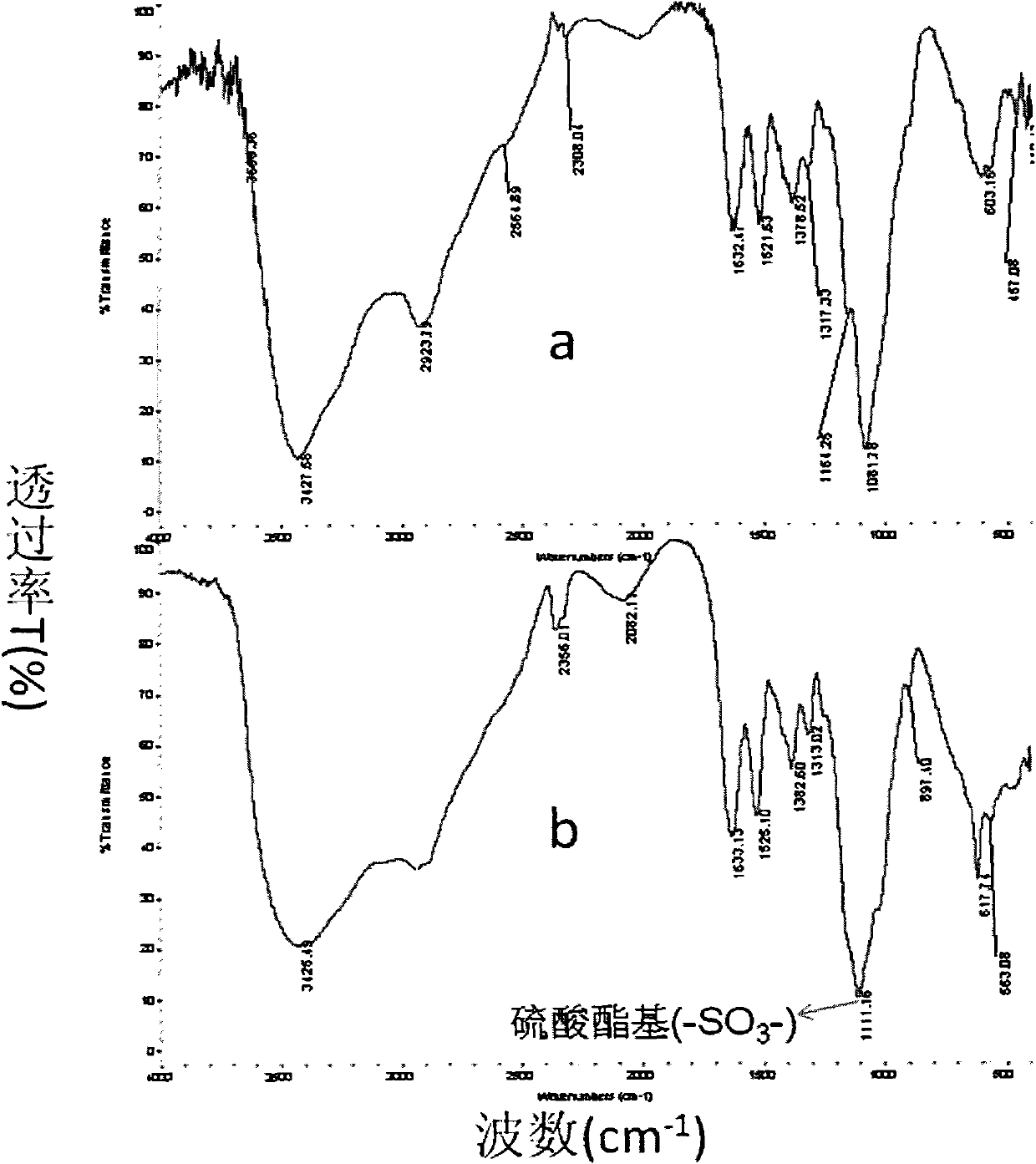

[0021] Dissolve 1g of chitosan in 100mL of distilled water, then add 0.1mol / L bisulfate solution, stir for 30-60min, adjust the pH with sodium hydroxide; freeze-dry the chitosan-bisulfate solution, The sulfation reaction was carried out under the condition of drying and heating at 80°C for 1 day; after the reaction, the chitosan-bisulfate was dissolved in distilled water and dialyzed for 2 days to remove unreacted bisulfate, and finally freeze-dried to obtain the sulfated shell polysaccharides. Gained sulfated chitosan is analyzed through infrared spectroscopy (IR), and at 1111cm -1 A sulfate group (-SO 3 -) stretching vibration peak; by measuring, the sulfate radical content of sulfated chitosan is 20.4%.

Embodiment 2

[0023] Dissolve 1g of chitosan in 100mL of distilled water, then add 0.1mol / L bisulfate solution, stir for 30-60min, adjust the pH with sodium hydroxide; freeze-dry the chitosan-bisulfate solution, The sulfation reaction was carried out under the condition of drying and heating at 100°C for 1 day; after the reaction, the chitosan-bisulfate was dissolved in distilled water and dialyzed for 2 days to remove unreacted bisulfate, and finally freeze-dried to obtain the sulfated shell polysaccharides. Gained sulfated chitosan is analyzed by IR, at 1111cm -1 A sulfate group (-SO 3 -) stretching vibration peak; by measuring, the sulfate radical content of sulfated chitosan is 18.6%.

Embodiment 3

[0025] Dissolve 1g of chitosan in 100mL of distilled water, then add 0.1mol / L bisulfate solution, stir for 30-60min, then adjust the pH with sodium hydroxide; freeze-dry the chitosan-bisulfate solution, The sulfation reaction was carried out under the condition of drying and heating at 100°C for 2 days; after the reaction, the chitosan-bisulfate was dissolved in distilled water and dialyzed for 2 days to remove unreacted bisulfate, and finally freeze-dried to obtain sulfation Chitosan. Gained sulfated chitosan is analyzed by IR, at 1111cm -1 A sulfate group (-SO 3 -) stretching vibration peak; by measuring, the sulfate radical content of sulfated chitosan is 18.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com