Heat-accumulating heat supply unit and heat-accumulating structure thereof

A heat supply unit and heat storage technology, applied in heating methods, heat storage equipment, household heating, etc., can solve the problems of low water heat capacity, inability to increase heat capacity, complex equipment, etc., and achieve increased heat storage and volume The effect of shrinking and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

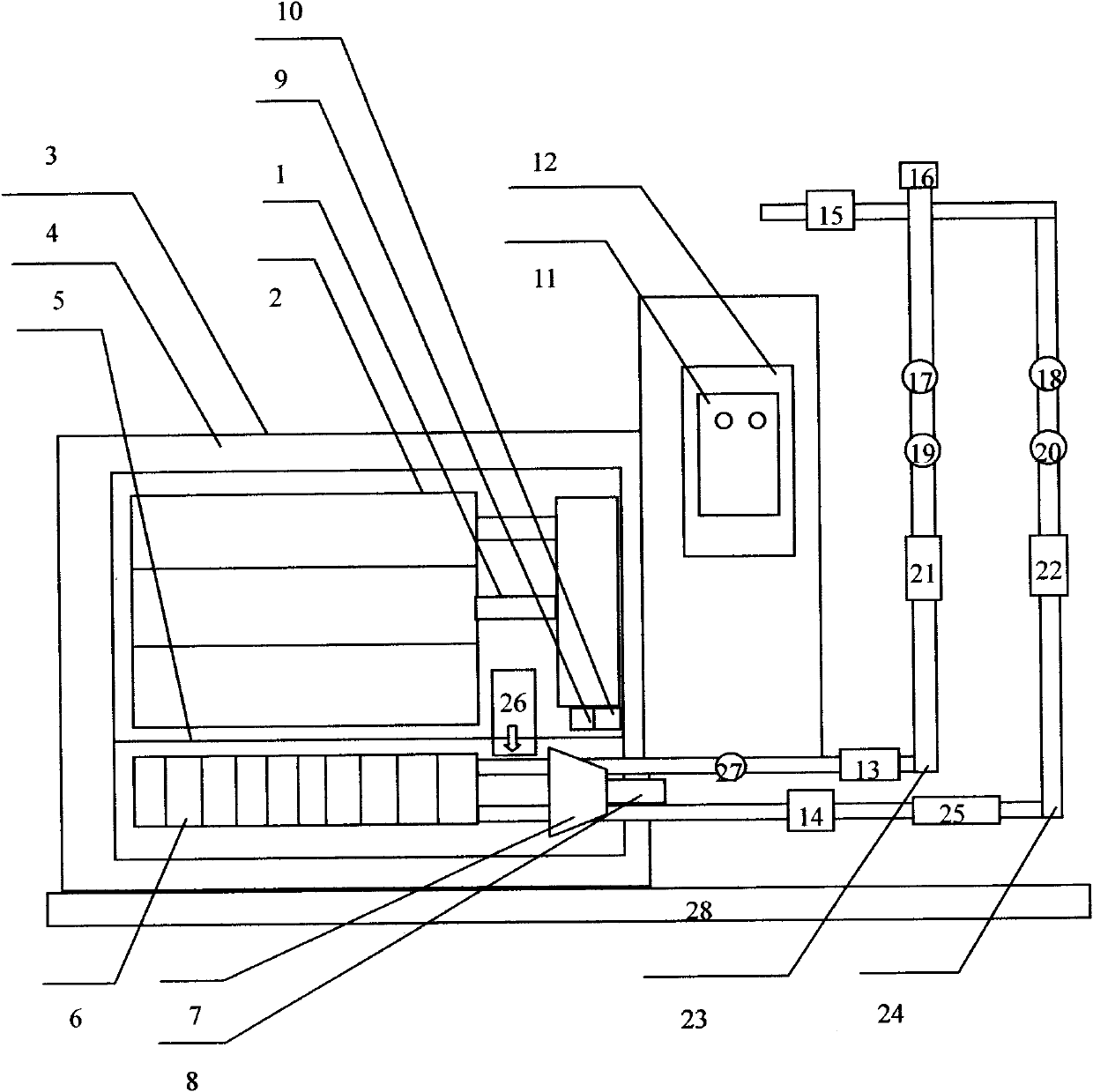

[0045] A certain factory is equipped with a regenerative heat supply unit provided by the present invention, which uses the heat accumulator provided by the present invention. The shell of the heat accumulator is a high-temperature heat insulating material 4, and the heat storage brick 2, the heat exchange pipe 6, the fan 7, and the electric heater 1 are arranged in the shell.

[0046] The heat storage brick 2 is an iron heat storage brick, preferably the main component is more than 85% of ferric oxide and some minerals; The calcium content is less than 1%, and there are a large number of spiral pores in the microscopic view. The heat storage brick 2 is a cuboid, and several, dozens to hundreds of blocks can be used in one heat accumulator.

[0047] The heat exchange pipe 6 is made of heat-resistant metal or alloy, which can be a nickel alloy pipe, stainless steel pipe, etc. In order to improve the heat exchange efficiency, it can be arranged in a coiled manner. In order to i...

Embodiment 2

[0064] The structure of this regenerative heat supply unit is the same as that of Embodiment 1, except that the regenerative bricks use magnesium oxide as the main raw material, and the heat storage temperature can also reach 100-800 degrees Celsius.

Embodiment 3

[0066] The structure of this regenerative heat supply unit is the same as that of Embodiment 1, except that the regenerative bricks use aluminum or silicate as the main raw material, and the heat storage temperature can also reach 100-800 degrees Celsius.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com