Pramlintide acetate slow release microballoon preparation and preparation method thereof

A technology of pramlintide acetate and microspheres, which is applied in the field of medicine, can solve problems such as short half-life, poor compliance, failure, etc., achieve stable preparation process, improve drug efficacy and economic benefits, and prolong the effect of drug action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

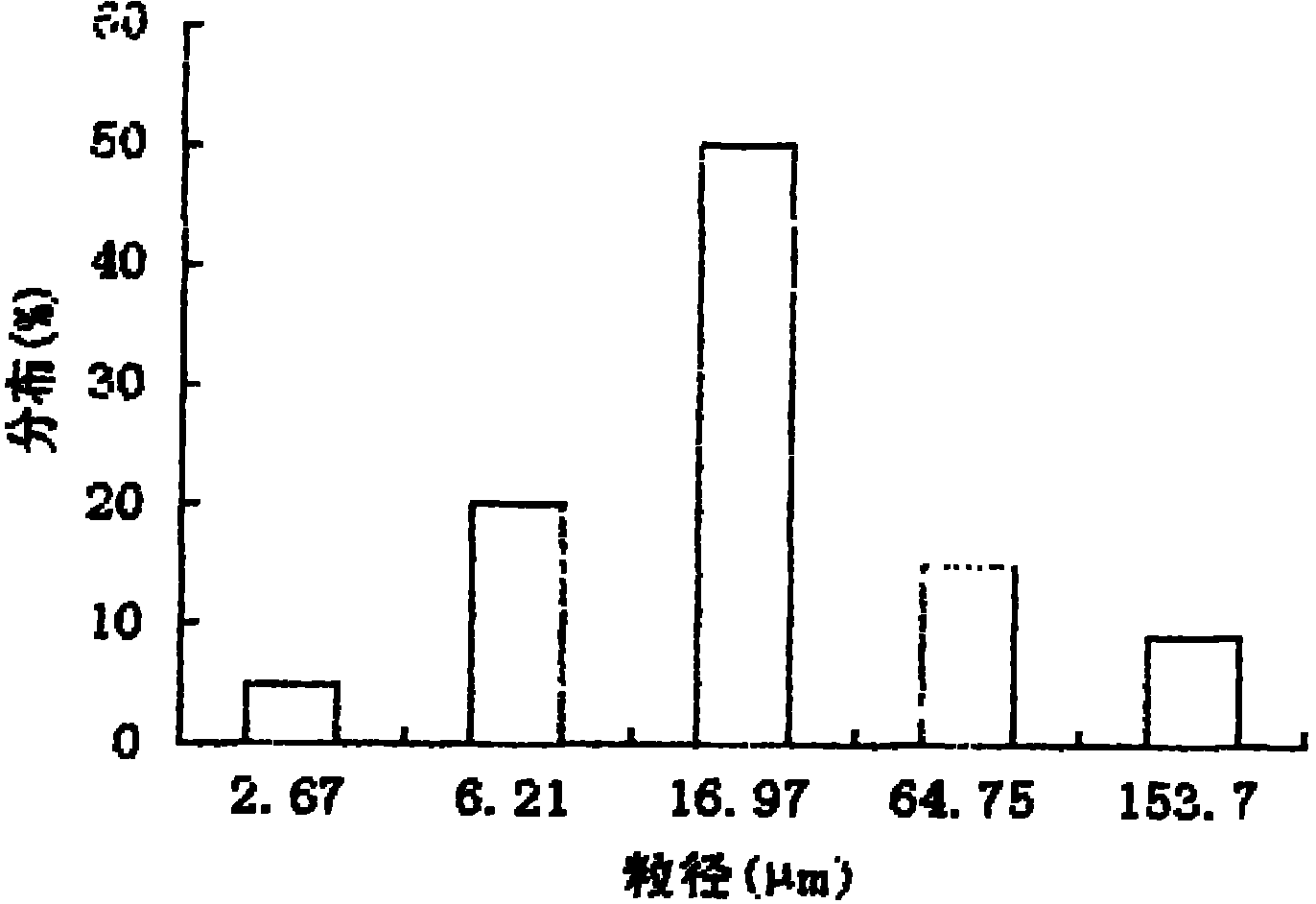

Embodiment 1

[0023] Accurately weigh 50mg of pramlintide acetate and dissolve it in 0.25ml pH7.4 PBS buffer to form an internal aqueous phase. Dissolve 400mg of PLGA (Mw=15000, 75:25) in 2ml dichloromethane to form an organic phase. Add the internal water phase to the organic phase, disperse and emulsify at a high speed at 10000rpm to form W / O colostrum. Place 120ml of 2% PVA solution (containing 10% NaCl) in a stirring vessel, and stir the colostrum at high speed (22000rpm ) In the case of 2% PVA solution 120ml (containing 10% NaCl) fully homogenized into W / O / W double emulsion, 2 minutes later, reduce the speed to 400rpm, and stir at low temperature (4~10℃) for 4 hours , After the microspheres are hardened, they are centrifuged and washed, and dried under vacuum at low temperature (4~10℃).

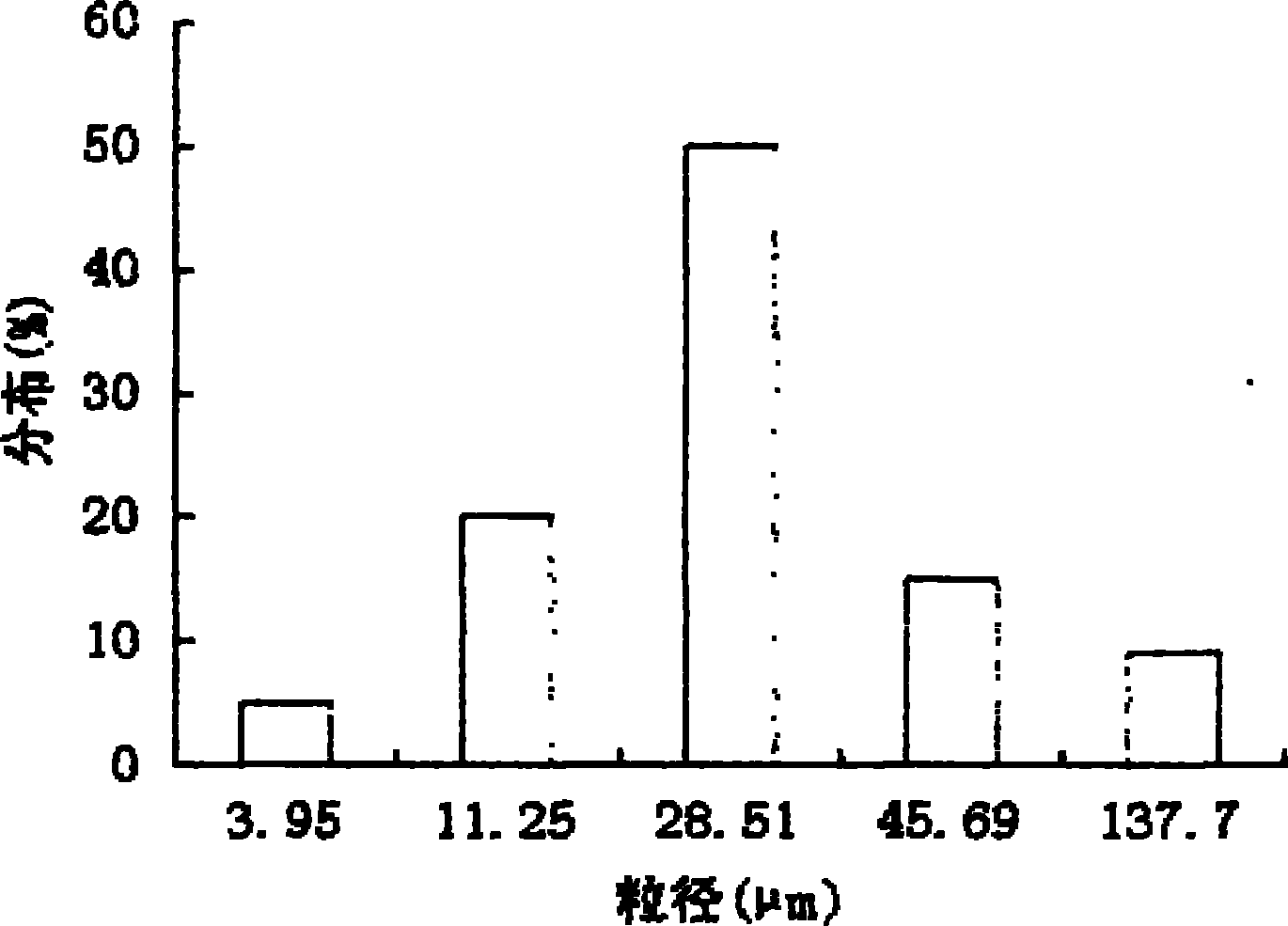

Embodiment 2

[0025] Accurately weigh 50mg of pramlintide acetate and dissolve it in 0.25ml pH7.4 PBS buffer to form an internal aqueous phase. Dissolve 400mg of PLGA (Mw=15000, 75:25) in 1.5ml dichloromethane to form an organic phase. Add the above internal water phase to the organic phase, disperse and emulsify at a high speed at 10000rpm to form W / O colostrum, place 120ml of 2% PVA solution (containing 10% NaCl) in a stirring vessel, and stir the colostrum at high speed ( 16000rpm) in the case of 2% PVA solution 120ml (containing 10% NaCl) fully homogenized into W / O / W double emulsion, after 2 minutes, reduce the speed to 400rpm, and stir at low temperature (4~10℃) 4 After hours, the microspheres are hardened by centrifugation and washed, and then vacuum dried at low temperature (4~10℃).

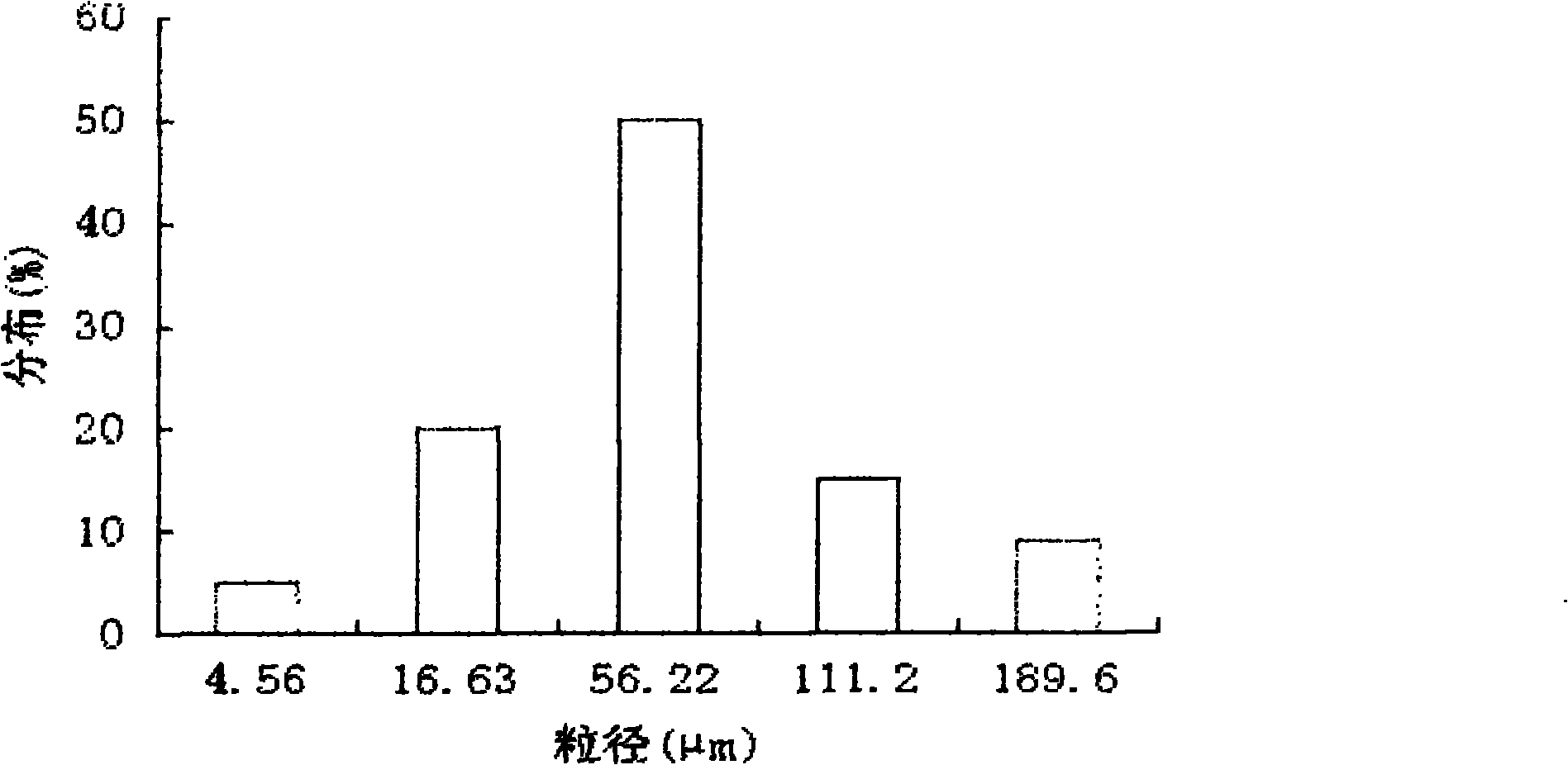

Embodiment 3

[0027] Accurately weigh 50mg pramlintide acetate and dissolve it in 0.25ml pH7.4 PBS buffer to form an internal aqueous phase. Dissolve 400mg PLGA (Mw=15000, 75:25) in 1ml dichloromethane to form an organic phase. Add the internal water phase to the organic phase, disperse and emulsify at a high speed at 10000rpm to form W / O colostrum. Place 120ml of 2% PVA solution (containing 10% NaCl) in a stirring vessel, and stir the colostrum at high speed (10000rpm ) In the case of 2% PVA solution 120ml (containing 10% NaCl) fully homogenized into W / O / W double emulsion, 2 minutes later, reduce the speed to 400rpm, and stir at low temperature (4~10℃) for 4 hours , After the microspheres are hardened, they are centrifuged and washed, and dried under vacuum at low temperature (4~10℃).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com