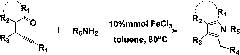

Method for preparing iron-catalyzed pyrrole and pyrrole cyclic compounds

A compound, pyrrole technology, which is applied in the field of preparation of pyrrole and pyrrolocyclic compounds, and achieves the effects of low price, green catalytic system, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Preparation of 4-pentynone compound 1a

[0025]

[0026] Into a 50 mL round bottom flask equipped with a magnetic stirrer was added anhydrous N,N-dimethylformamide (DMF) (15 mL), N-acetoacetanilide (1.77 g, 10 mmol) and anhydrous potassium carbonate (1.66 g , 12mmol), slowly add 3-bromopropyne (1.43g, 12mmol) dropwise at a room temperature of 20°C under stirring, at a rate of 1 drop / 2 seconds. Stirring was continued for 12 hours to obtain a light yellow reaction liquid. The reaction solution was poured into saturated aqueous sodium chloride solution (20mL), extracted with dichloromethane (3×15mL), and the organic phases were combined, then backwashed with water (3×10mL), dried over anhydrous calcium chloride, Steps such as suction filter, vacuum distillation obtain viscous solid, through silica gel column chromatography (eluent is V 石油醚 :V 乙酸乙酯 =10:3) to obtain 1.25 g of white solid, the structure of the product was confirmed by NMR and MS to be 4-pentynone com...

Embodiment 2

[0033] Replace 4-chloroaniline in "Example 1" with 2-naphthylamine, use benzene as solvent, and the reaction temperature is 50°C. Other conditions are the same as "Example 1". The experimental results are shown in Table 1.

[0034]

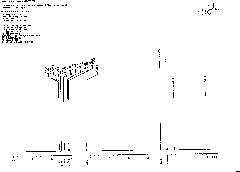

[0035] Spectrum analysis data 2b:

[0036] 1 H NMR (500MHz, CDCl 3 )δ=2.04(s, 3H), 2.39(s, 3H), 6.24(s, 1H), 7.07-7.97(m, 13H); 13 CNMR (125MHz, CDCl 3 )δ=12.13, 12.55, 104.10, 114.14, 119.52, 123.21, 125.52, 126.65, 126.74, 127.59, 127.74, 128.64, 128.89, 129.17, 132.51, 133.00, 134.73, 1368.028 -1 ) 3257, 3057, 1638, 1596, 1577, 1498, 1309, 1257, 795, 759, 690;

Embodiment 3

[0038] Replace 4-chloroaniline in "Example 1" with benzylamine, meanwhile, use FeBr 3 , other conditions are the same as "Example 1", and the experimental results are shown in Table 1.

[0039]

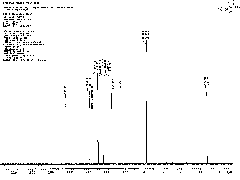

[0040] Spectral analysis data 2c:

[0041] 1 H NMR (500MHz, CDCl 3 )δ=2.15(s, 3H), 2.52(s, 3H), 5.05(s, 2H), 6.16(s, 1H), 6.90(d, J=8.0Hz, 2H), 7.06-7.34(m, 5H ), 7.49(s, 1H), 7.59(d, J=8.0Hz, 2H); 13 C NMR (125MHz, CDCl 3 )δ=11.17, 12.21, 46.68, 61.49, 104.32, 113.96, 119.72, 123.39, 125.45, 127.36, 128.20, 128.84, 128.85, 134.54, 136.90, 138.63, 164.09; -1 )3249, 3027, 1638, 1536, 1495, 1435, 1250, 753, 691; MS m / z Calcd: 304.2; Found: 305.2 [(M+1) + ].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com