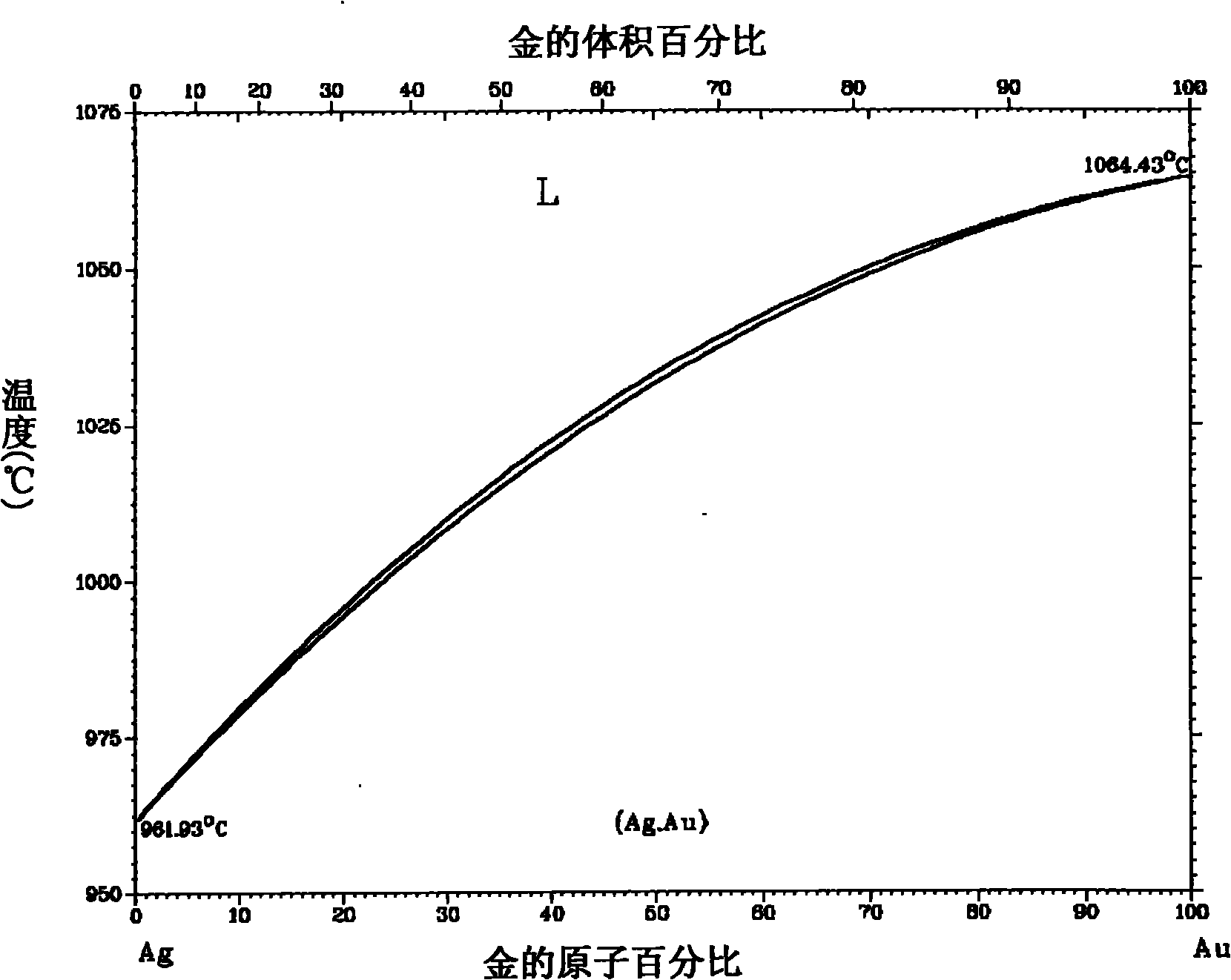

Silver-gold alloy target material, manufacturing method and application thereof

A manufacturing method and alloy target technology, which is applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problems of small grain size, expensive equipment, and reduced material purity, so as to achieve finer grain size and reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

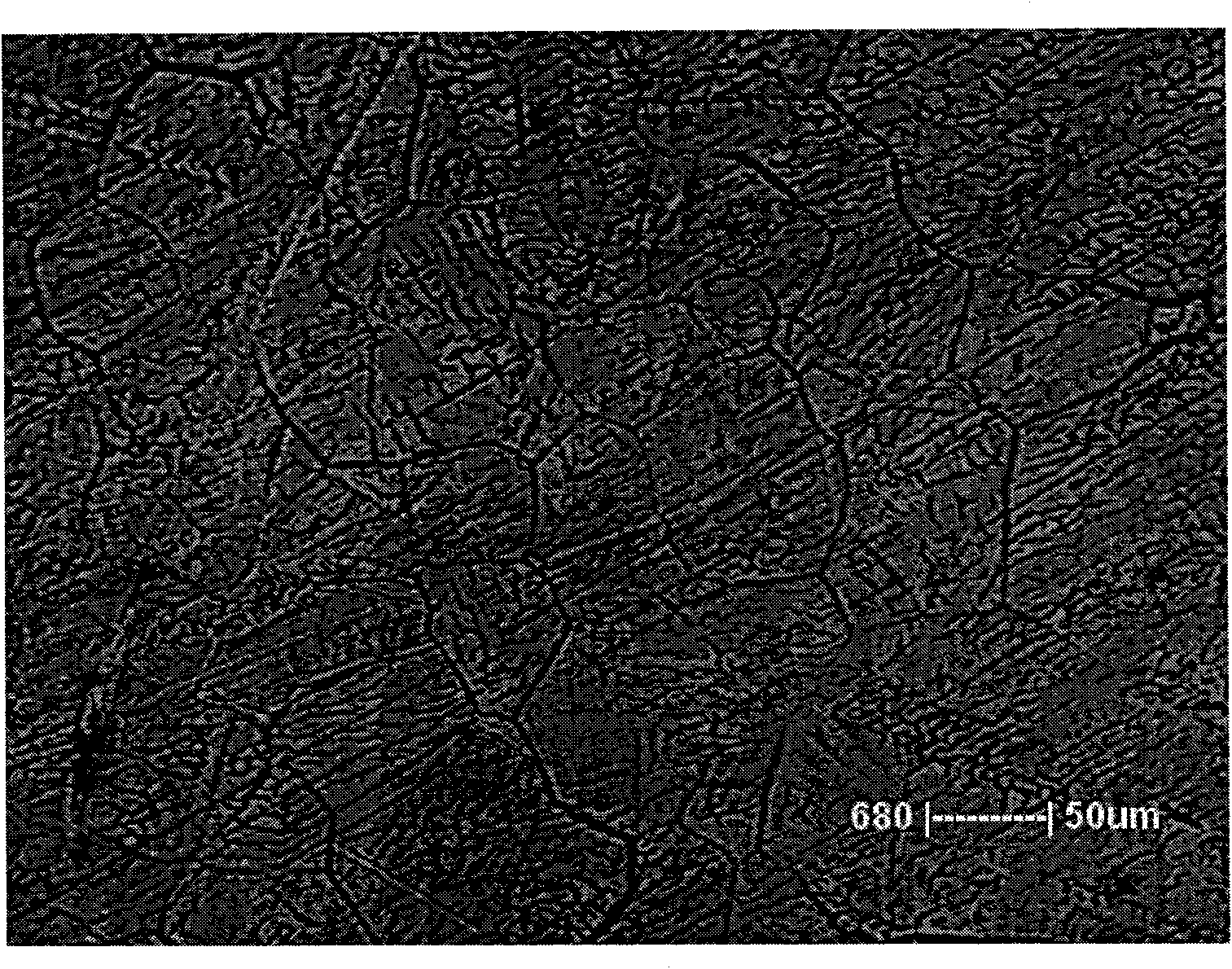

[0049] Take 1 kg of gold and 9 kg of silver into the crucible of an induction melting furnace, heat it to 1075 ° C to melt it; pour the molten soup in the crucible into a cylindrical mold, and wait for it to cool to about 800 ° C Hot forging, the compression ratio of hot forging is about 70%; cold rolling is carried out after the embryo body is cooled, and the rolling ratio is about 60%; the rolled embryo body is put into a heat treatment furnace at 600°C for about 1 Hours of recrystallization heat treatment; dimension machining after heat treatment to obtain silver-gold alloy targets.

[0050] Please see figure 2 , which is a photomicrograph showing the silver-gold alloy target obtained above (microscope model: Olympas BH, image processing software: Image-Pro Plus version 6.3), and the crystal grains of the silver-gold alloy target can be known The size is less than 250 μm.

Embodiment 2

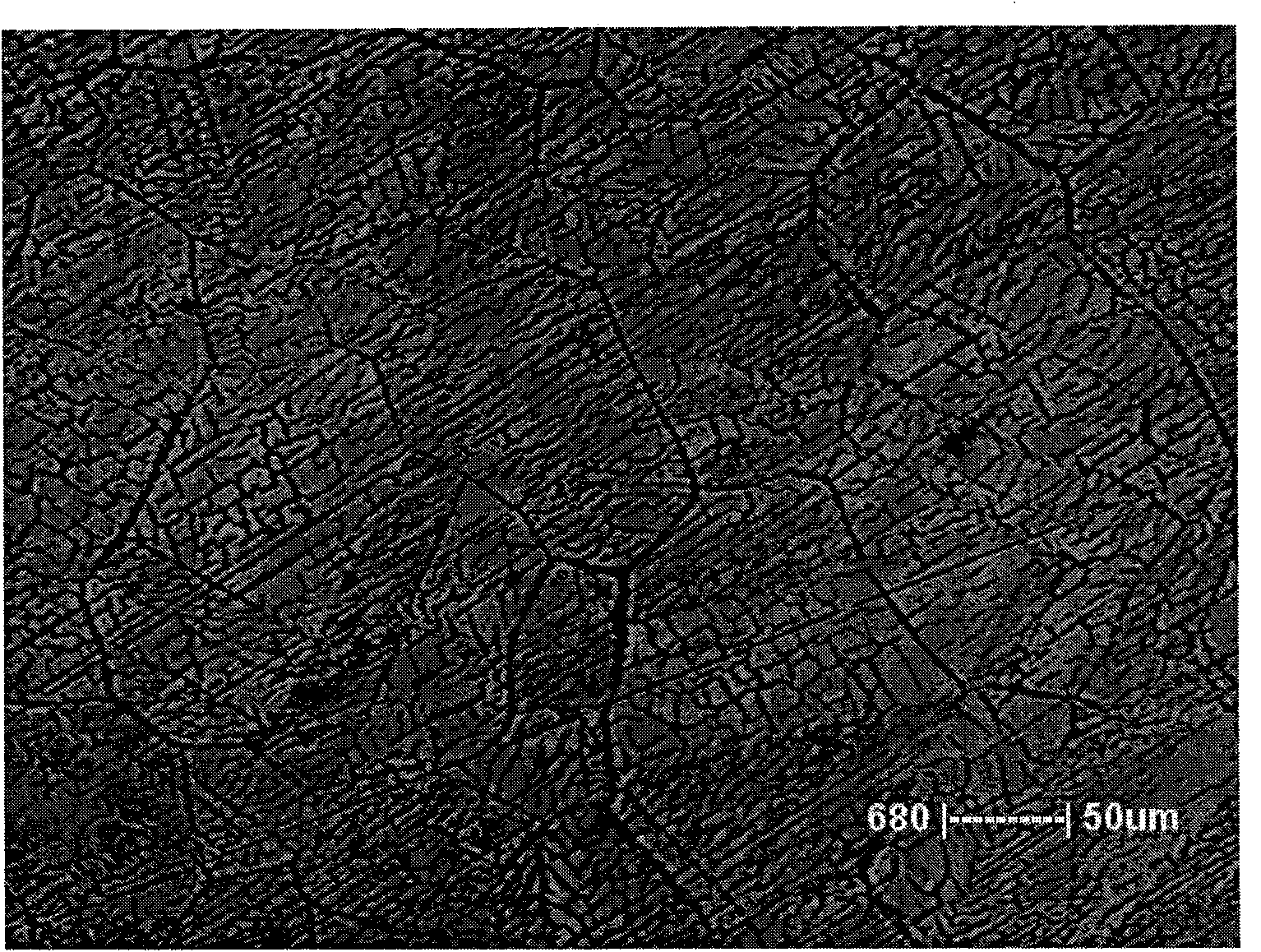

[0052] Take 5kg of gold and 5kg of silver into a crucible of an induction melting furnace, heat it to 1125°C to melt it; pour the molten soup in the crucible into a cylindrical mold, and wait for it to cool to about 800°C Hot forging, the compression ratio of hot forging is about 75%; cold rolling is carried out after the embryo body is cooled, and the rolling ratio is about 65%; the rolled embryo body is put into a heat treatment furnace at 650°C for about 1 Hours of recrystallization heat treatment; mechanical processing after heat treatment.

[0053] Please see image 3 , which is a photomicrograph showing the silver-gold alloy target obtained above, and it can be known that the grain size of the silver-gold alloy target is less than 300 μm.

Embodiment 3

[0055]Take 9 kg of gold and 1 kg of silver into the crucible of an induction melting furnace, heat it to 1165°C to melt it; pour the molten soup into a cylindrical mold, and wait for it to cool to about 800°C for hot forging , the compression ratio of hot forging is about 80%; cold rolling is carried out after the embryo body is cooled, and the rolling ratio is about 65%; the embryo body after rolling is put into a heat treatment furnace at 700 ℃ for about 1 hour Crystallization heat treatment; mechanical processing after heat treatment.

[0056] It also undergoes the same analysis method as in the previous embodiment, and it is known that the grain size of the silver-gold alloy target is less than 300 μm.

[0057] The process conditions of the above-mentioned Examples 1-3 and the grain size of the obtained silver-gold alloy target are all sorted out as shown in Table 1 below:

[0058] Conditions and results of the silver-gold alloy target material in each embodiment of Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com