Bottom cathode diversion type rare earth electrolysis cell

A bottom cathode and electrolytic cell technology, applied in the field of metallurgy, can solve problems such as the great influence of molten metal, restriction amplification, heat loss, etc., and achieve the effects of increasing metal yield, reducing metal secondary oxidation, and reducing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

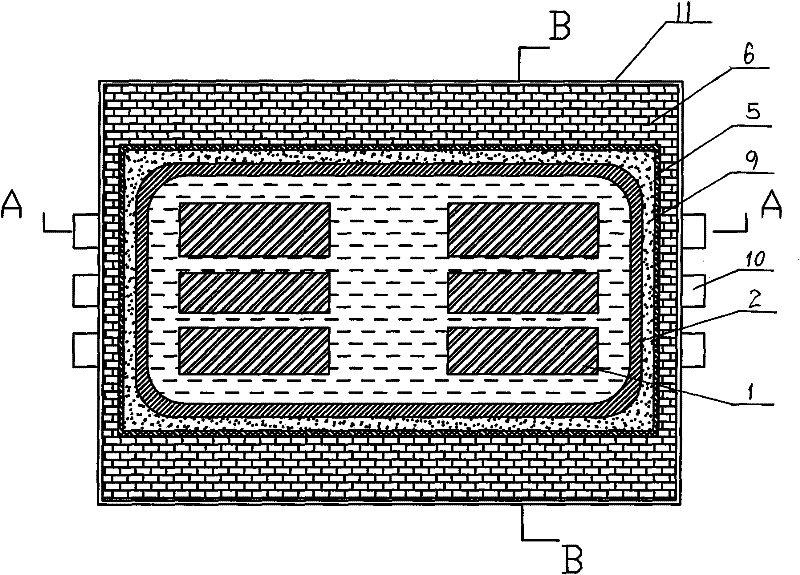

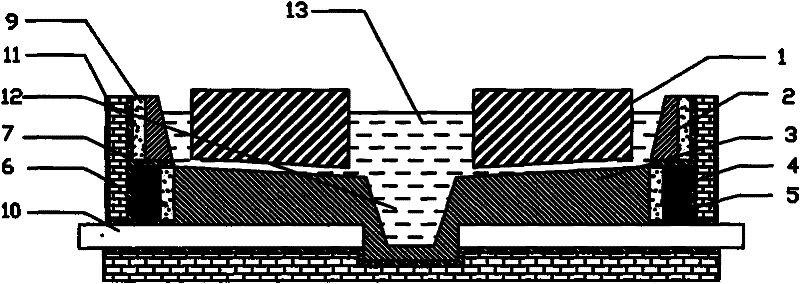

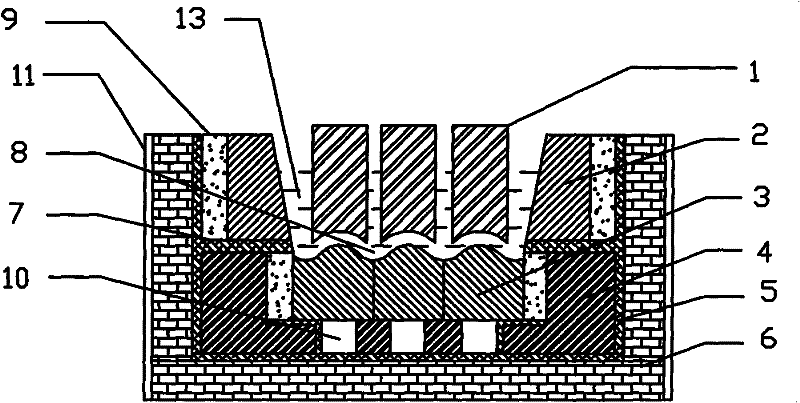

[0015] as attached figure 1 , with figure 2 , with image 3 As shown, the present invention includes: anode 1, graphite crucible 2, cathode, refractory layer 4, insulation layer 5, heat preservation layer 6, high temperature insulation layer 7, diversion groove 8, carbon powder layer 9, cathode conductive row 10, protective layer 11. Metal collector 12, electrolyte 13. The body of the rare earth electrolytic cell is a masonry square or trapezoidal graphite crucible 2 with a large top and a small bottom. The trapezoidal graphite crucible 2 with a large upper opening and a smaller lower opening is used to facilitate gas discharge. The carbon powder layer 9 is filled between the graphite crucible 2 and the insulating layer 5, so that the electrolysis can be ensured without leakage, the utilization rate of electric energy can be improved, and the energy consumption can be reduced. The refractory layer 4, thermal insulation layer 6 and protective layer 11 are built on the perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com