Novel CO2 cycloaddion ionic liquid catalyst and preparation method thereof

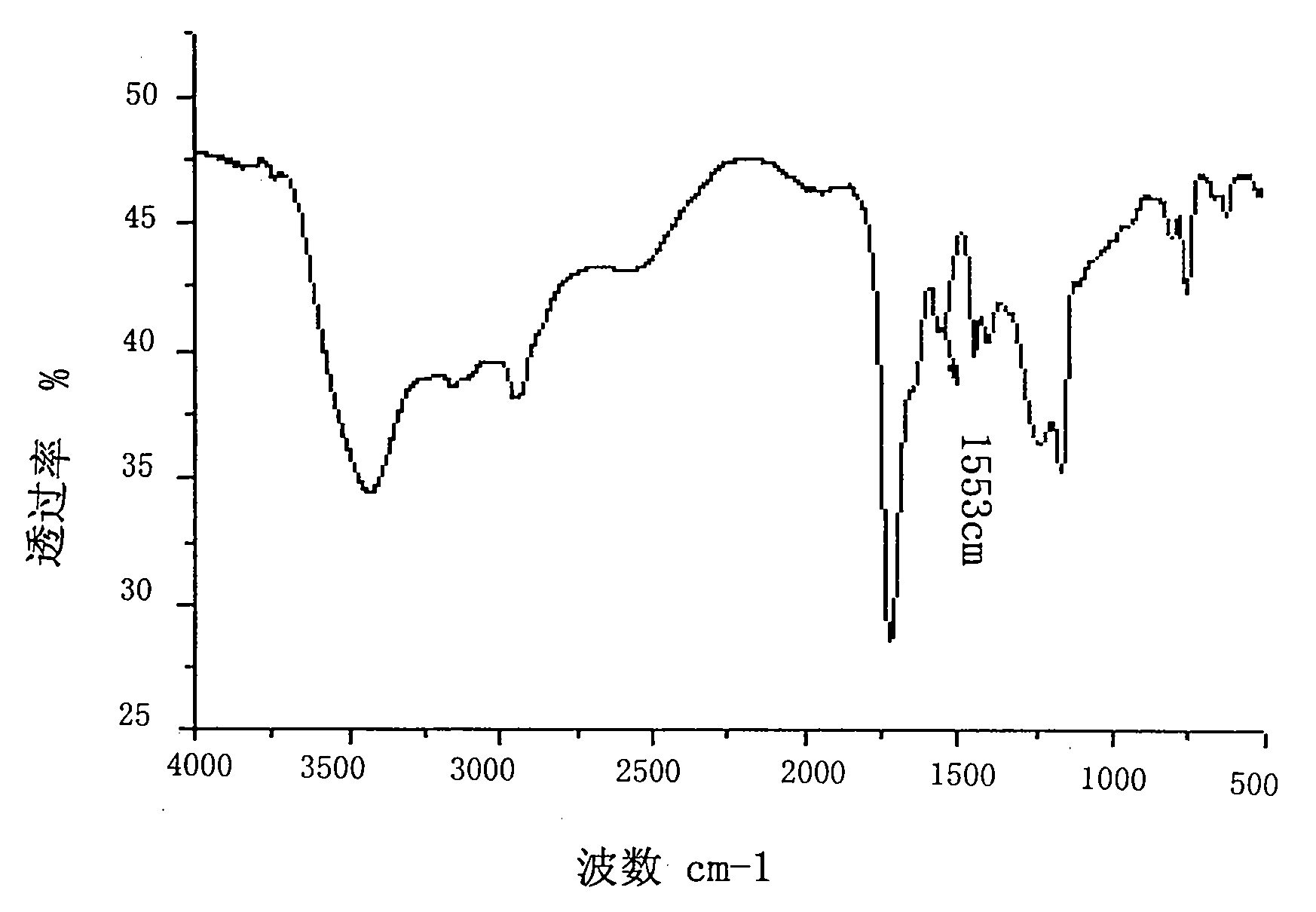

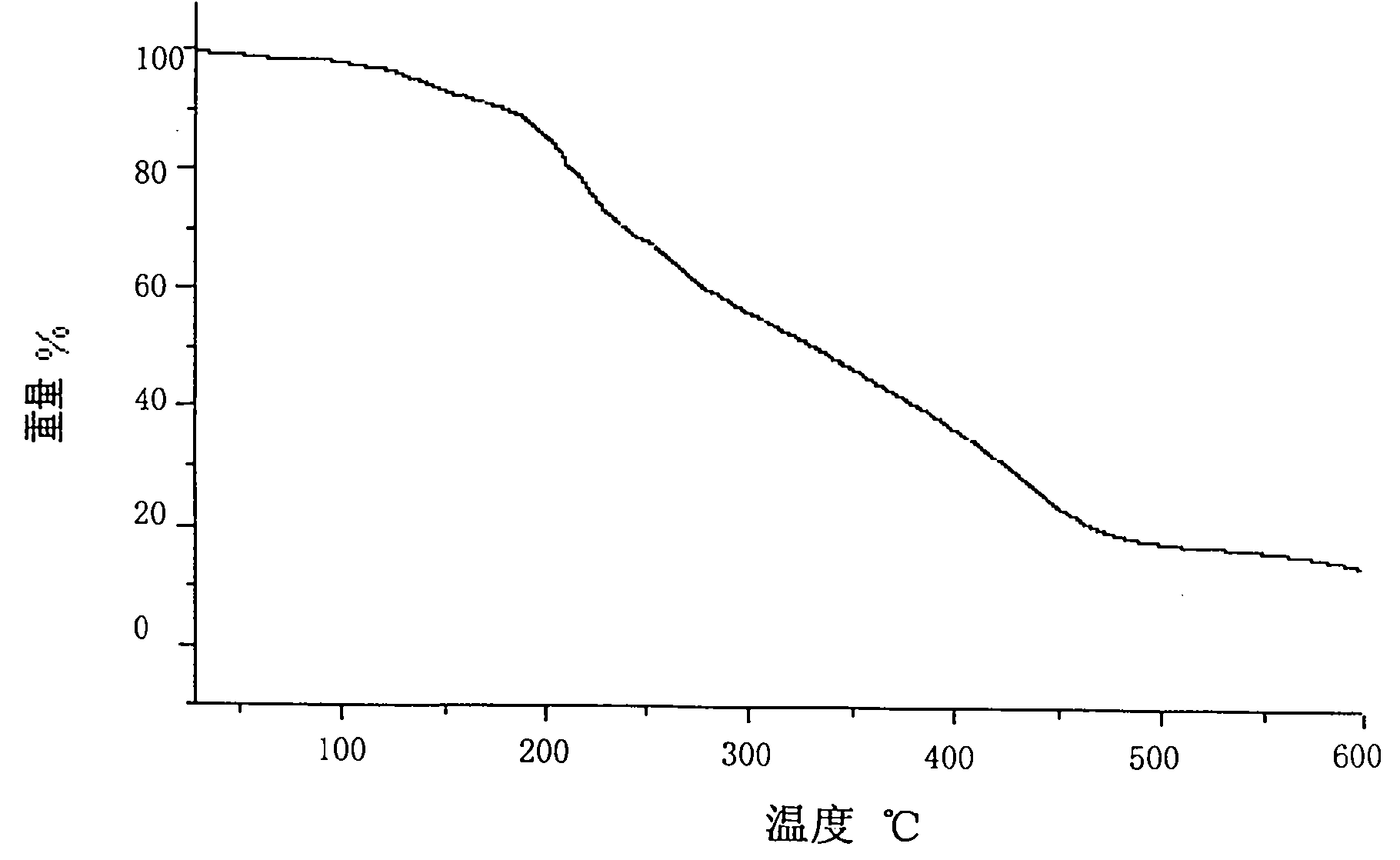

A technology of liquid catalysts and reactive ions, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unsatisfactory catalyst activity and unsuitable for industrial production, etc., to achieve large-scale The effect of production, low cost and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, new CO 2 Preparation of Cycloaddition Catalysts

[0046] 1. Synthesis of chlorinated 1-allyl-3-methylimidazolium ionic liquid: mix N-methylimidazole and allyl chloride at a molar ratio of 1:1.11, heat to 55°C, and react under nitrogen protection 8h, 1-allyl-3-methylimidazolium chloride ionic liquid was obtained, yield: 78%.

[0047] 2. Preparation of ionic liquid by copolymerization of 1-allyl-3-methylimidazolium chloride ionic liquid and acrylic acid: mixing 1-allyl-3-methylimidazolium chloride ionic liquid with acrylic acid in a molar ratio of 1:8 , then add N,N-dimethylformamide (DMF) with 2 times the molar weight of acrylic acid and azobisisobutyronitrile with 1% molar weight of acrylic acid, react at 70°C for 24h under the protection of nitrogen, and then precipitate with chloroform, Filter to obtain a light yellow polymer, and dry it in a vacuum oven at 100°C for 24 hours. Yield: 51%.

Embodiment 2

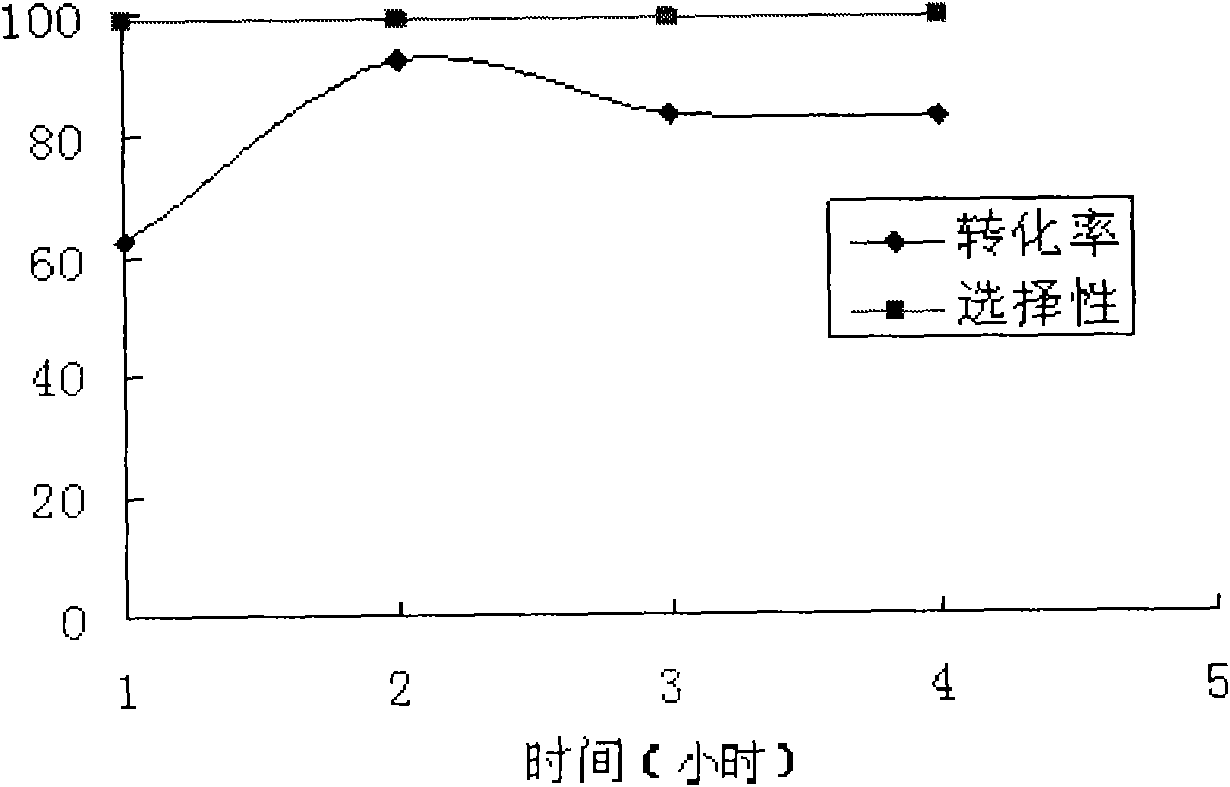

[0048] Embodiment 2, catalytic CO 2 cycloaddition reaction

[0049] Add 10ml of epichlorohydrin, magneton, and 0.1g of the catalyst of the present invention into a 50mL stainless steel autoclave. After replacing the air, first raise the temperature to 150° C., then pass carbon dioxide, adjust the pressure of the reactor to 1.25Mpa, and stir. When reacting for 1h. After the reaction was completed, it was cooled with an ice-salt bath, and then deflated, and the obtained mixture was filtered to obtain the corresponding cyclocarbonate. The conversion rate was 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com