Method for extracting high-purity phospholipid from sleeve-fish-processing waste

A waste, high-purity technology, applied in the direction of edible phospholipid composition, food science, bulk chemical production, etc., can solve the problem of no extraction of phospholipids, etc., achieve easy operation and automatic control, reduce environmental pollution, and good quality Effect

Inactive Publication Date: 2010-08-25

QINGDAO HAIENCI BIOENG

View PDF2 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

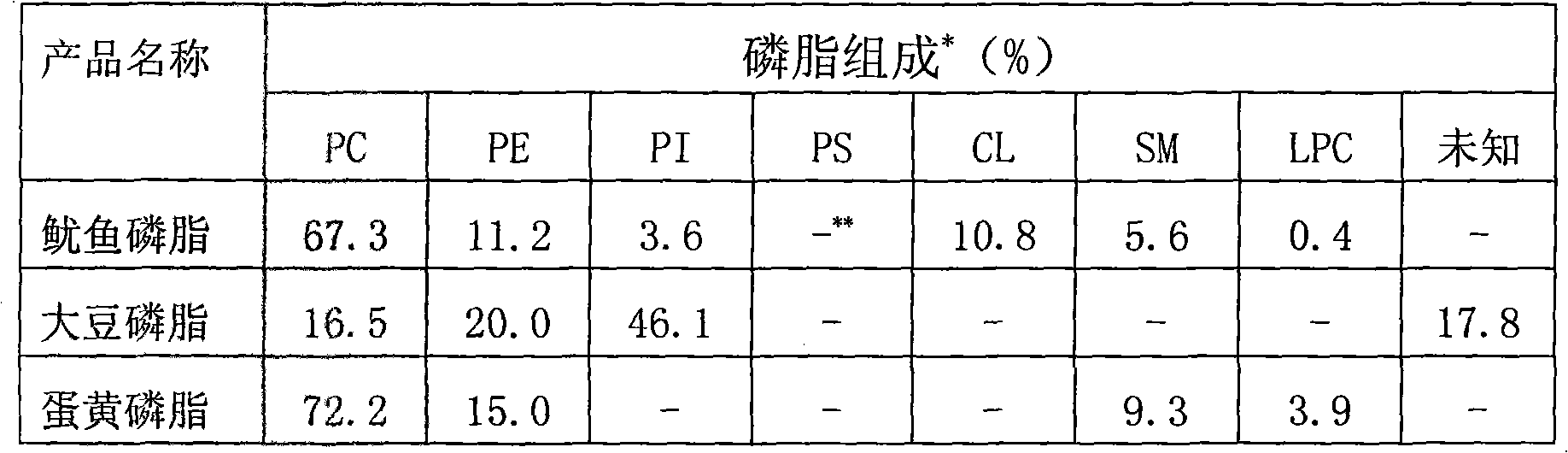

At present, the supercritical fluid extraction method has been well applied in the extraction and preparation of terrestrial animal and plant phospholipids such as soybean phospholipids and egg yolk phospholipids, but it has not been used to extract and prepare marine animals, especially squid and their processing waste. Published reports on phospholipids

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention, which belongs to the technical field of substance extraction, relates to a method for extracting high-purity phospholipid from sleeve-fish-processing waste. Fresh sleeve-fish-processing waste is first dried until the moisture content is less than or equal to 3 percent, and is ground to 10 to 80 meshes; the preprocessed powdery material is then loaded into an extraction kettle, and after the air is removed, extracting solvent CO2 is injected to set pressure; the supercritical extraction and separation of the extraction system is regulated as three processes, i.e. extraction, primary separation and secondary separation, raffinate is taken out of the extraction kettle after triglycercide and cholesterol are separated and removed, ethanol which is 4 to 10 times the weight of the raffinate is added in the raffinate according to a weight ratio to dissolve the raffinate, clear solution is taken out and concentrated, and is then washed by acetone, the obtained solid substance is dissolved in ethanol and then mixed with water, and precipitate which is obtained by centrifugation is dried, so that sleeve-fish phospholipid is obtained. The method has the advantages of less organic solvent dosage, little environment pollution, simple processing equipment, easy operation, automatic control, stable product quality, low production cost, good quality and high purity.

Description

Technical field: The invention belongs to the technical field of extraction and preparation of material components, and relates to a method for extracting high-purity phospholipids from squid processing waste, using supercritical CO 2 Extraction technology and equipment separate and extract the active ingredients in natural products and process them. Background technique: Phospholipids are lipids containing phosphate radicals, which are the basic components of tissue cells and have important biological functions. The highly unsaturated fatty acids contained in phospholipids are an important source of polyenoic acid in the human body; phospholipids can reduce the content of cholesterol triglycerides in the blood, improve lipid metabolism and arteriosclerosis; phospholipids are typical compatible molecules with relatively Good emulsifying function is the basic component of liposome and an important component of total intravenous nutrition emulsion. It has high medical value a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07F9/10

CPCY02P20/54

Inventor 韩增晓胡爱芳

Owner QINGDAO HAIENCI BIOENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com