Method for preparing ultrahard erosion-resistant amorphous steel coating

An amorphous steel, erosion-resistant technology, applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of unsatisfactory coating structure and performance, unfavorable amorphous phase, low spraying speed, etc. Achieving good glass forming ability, low porosity and concentrated jet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

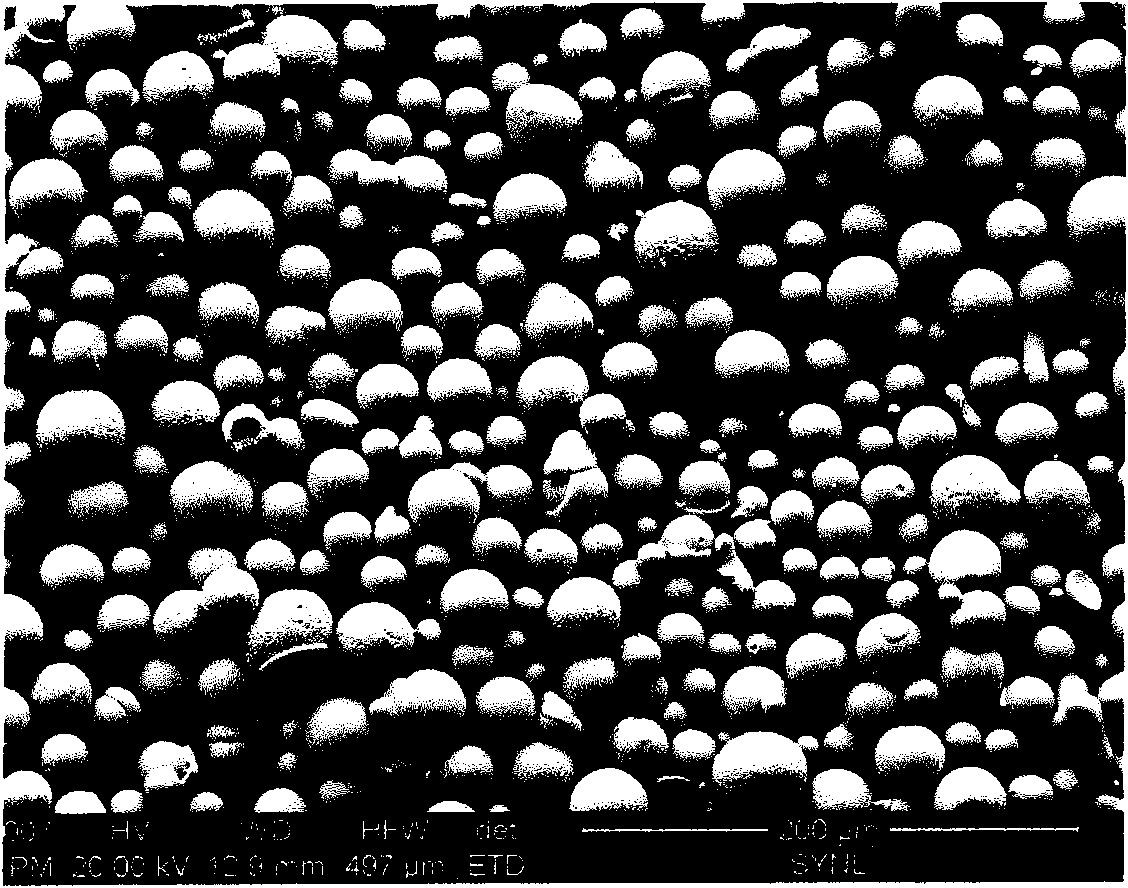

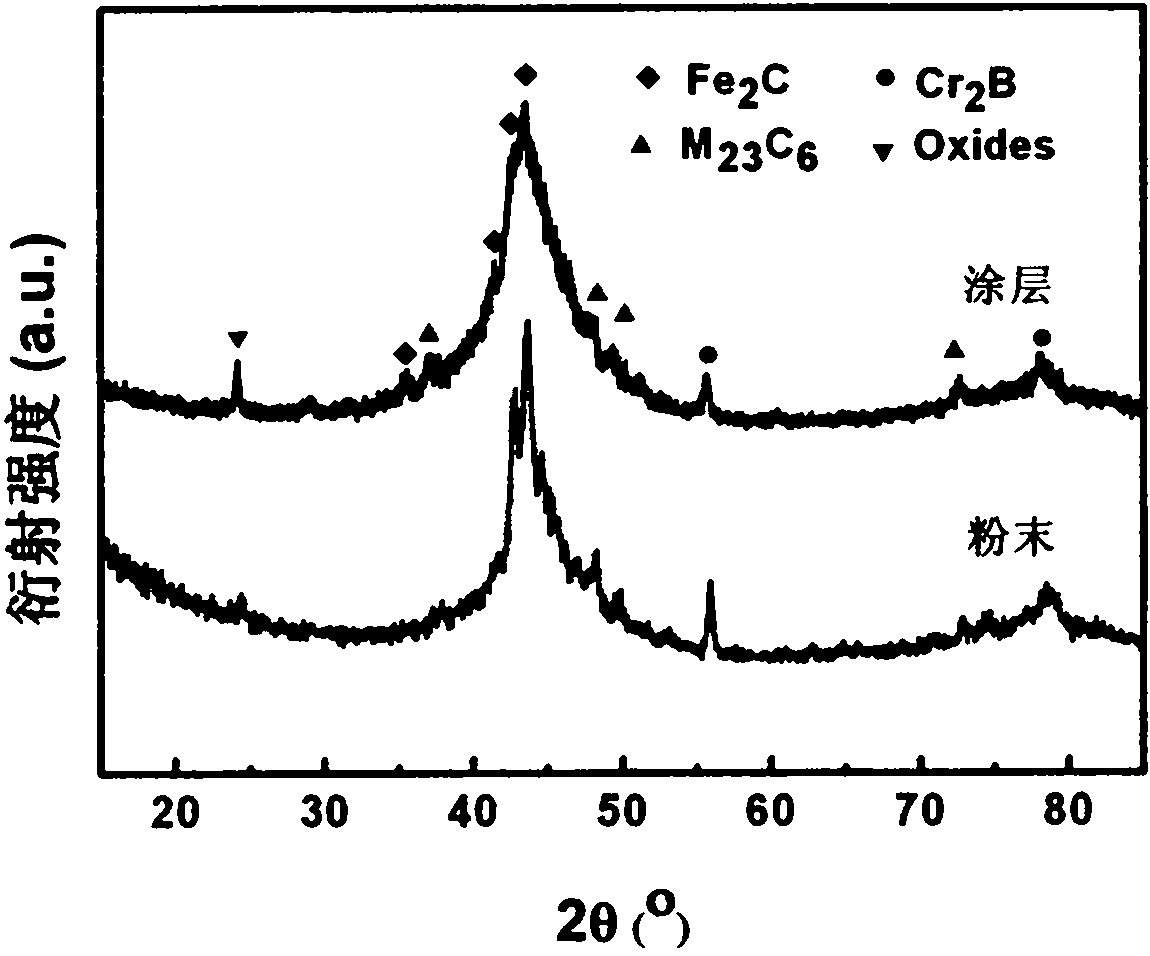

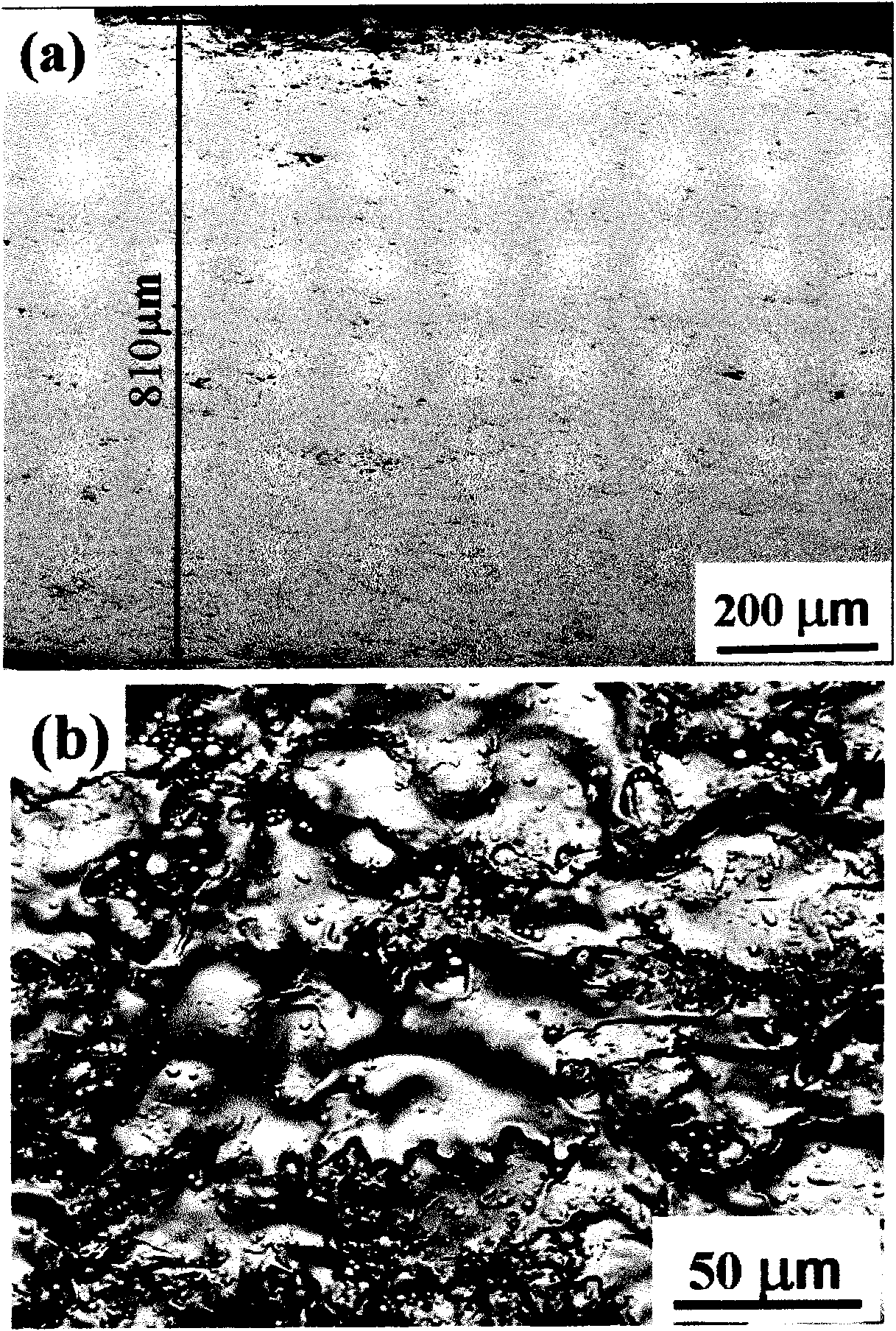

[0034] Firstly, the master alloy of the alloy was prepared by vacuum induction melting, and the alloy composition was Fe54.2; Cr 18.3; Mo 13.7; Mn 2.0; W 6.0; B 3.3; C 1.1; Si 1.4 (wt.%). Then the master alloy was put into an ultrasonic gas atomization heating furnace, and the process was optimized to prepare amorphous steel powder. The specific process parameters of gas atomization are: atomization temperature 1400K, atomization pressure 7MPa. The morphology of the powder particles is shown in Figure 1. It can be seen from the figure that the powder is mostly spherical with a small amount of satellite organization. The powder has excellent fluidity and filling property, about 0.25s / g. It is suitable as a precursor powder for thermal spraying. The X-ray diffraction results of the powder are shown in Figure 2. The figure shows that due to the limited cooling rate in the atomization and the limited ability of the material to form amorphous, there is a certain crystal phase in...

Embodiment 2

[0040] The difference from Example 1 is:

[0041] The alloy composition of this embodiment is Fe 59.3; Cr 19.8; Mo 5.5; Mn 2.1; W 6.8; B 3.8; min, spray distance 125mm, spray current 220A. Results The prepared ultra-hard and highly erosion-resistant amorphous steel coating had a thickness of 700 microns, increased porosity and oxygen content, an amorphous phase volume content of about 70%, and a microhardness of about 1170HV. The erosion performance is slightly better than in Example 1, but the corrosion performance is reduced.

Embodiment 3

[0043] The difference from Example 1 is:

[0044] The alloy composition of this embodiment is Fe 58.4; Cr 17.3; Mo 8.2; Mn 2.6; W 7.8; B 2.3; The amount is 90g / min, the spraying distance is 150mm, and the spraying current is 220A. Results The prepared ultra-hard and highly erosion-resistant amorphous steel coating had a coating thickness of 750 microns, a slightly increased porosity and oxygen content, an amorphous phase volume content of about 77%, and a microhardness of about 1050HV. There is no significant change in performance and erosion resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com