Method for observing real topography of nonmetallic inclusion in steel

A technology for non-metallic inclusions and observation of steel, which is applied in the field of characterizing the appearance of non-metallic inclusions in steel, can solve problems such as interference, difficult operation, and difficulty in directly observing the three-dimensional appearance of non-metallic inclusions in steel, achieving The effect of complete shape and simple sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

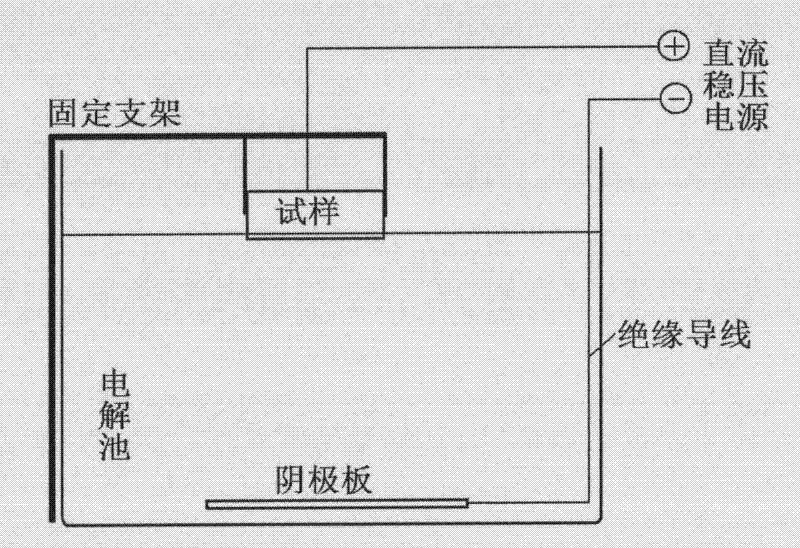

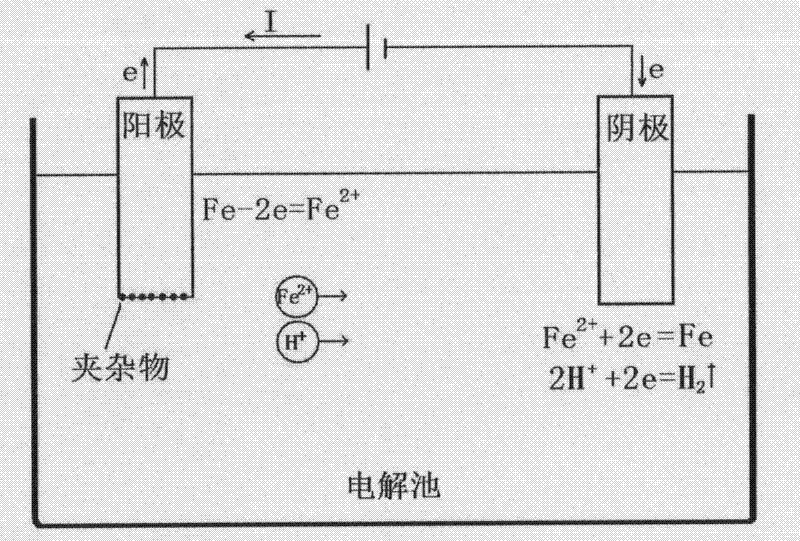

Embodiment 1

[0051]Adopting the technical scheme of the present invention, the ultra-low carbon IF steel produced by a certain steel factory is analyzed by taking a steel sample before deoxidation without adding Al. Process the steel samples taken in each process into a metallographic sample of 10mm×10mm×10mm, and use 240#, 400#, 600#, 800#, 1000#, 1200# sandpaper to polish the surface of the sample to be observed respectively before Throw it into a mirror surface, prepare a mixed solution of bromine water and acetone with a volume ratio of 0.5:1, and add 5% HCl solution with a mass concentration of 10% as an electrolyte. figure 1 It is a schematic diagram of the electrolysis device of the present invention, the observation surface of the steel sample is immersed in the electrolyte, and the positive pole of the DC stabilized power supply is connected as the anode, and the stainless steel sheet is used as the cathode, the control current is 0.05A, the erosion time is 20 minutes, and the eros...

Embodiment 2

[0054] Adopting the technical scheme of the present invention, the ultra-low carbon IF steel produced by a steel factory is deoxidized with Al for 3 minutes and then sampled for analysis. Process the steel samples taken in each process into a metallographic sample of 10mm×10mm×10mm, and use 240#, 400#, 600#, 800#, 1000#, 1200# sandpaper to polish the surface of the sample to be observed respectively before Throw it into a mirror surface, prepare a mixed solution of bromine water and acetone with a volume ratio of 2:1, add 10% NaCl solution with a mass concentration of 20% as the electrolyte, immerse the observation surface of the steel sample in the electrolyte, and Connect the positive electrode of the DC stabilized power supply as the anode, and the copper sheet as the cathode, control the current to 0.15A, the erosion time is 40 minutes, and the erosion thickness is 132 μm.

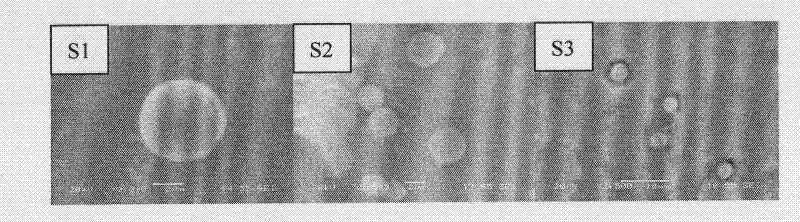

[0055] The three-dimensional morphology of non-metallic inclusions was observed by scanning electro...

Embodiment 3

[0057] Adopting the technical solution of the present invention, the ultra-low carbon IF steel cast slab produced by a certain steel factory is sampled and analyzed. Process the steel samples taken in each process into a metallographic sample of 10mm×10mm×10mm, and use 240#, 400#, 600#, 800#, 1000#, 1200# sandpaper to polish the surface of the sample to be observed respectively before Throw it into a mirror surface, prepare a mixed solution of bromine water and acetone with a volume percentage of 9:1, and then add 5% KCl solution with a mass concentration of 5% as the electrolyte, immerse the observation surface of the steel sample in the electrolyte, and Connect the positive electrode of the DC stabilized power supply as the anode, and the aluminum sheet as the cathode, control the current to 0.08A, the erosion time is 30 minutes, and the erosion thickness is 53 μm.

[0058] The three-dimensional morphology of non-metallic inclusions was observed by field emission electron mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com