Semimetal ceramic matrix air disc brake pad and production method thereof

A technology of disc brake pads and base air pressure, applied in the direction of brake discs, friction linings, mechanical equipment, etc., can solve problems such as high-temperature wear performance that is prone to cracks, reduced service life of brake pads, and aggravated high-temperature wear of materials, etc., to achieve Large braking torque, less ash falling, no obvious fading effect

Inactive Publication Date: 2010-08-25

HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

View PDF4 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

3. Since the wearable thickness of the friction lining of the air disc brake is 20mm, while the wearable thickness of the friction lining of the drum brake is less than 10mm, under the same conditions of use, the replacement cycle of the friction lining of the disc brake is shorter than that of the drum brake. The brakes are much longer: if the difference in the cooling capacity of the two brakes is taken into account, the difference in their replacement cycle can reach more than 3 times

In terms of the formula characteristics of the brake pads, the temperature on the surface of the brake pads and brake discs is as high as 500-700°C when the car is braked. Since the resin-based brake pads will decompose and release water, gas, oil, etc. at high temperatures, they will form on the friction surface. A layer of thin film makes dry friction into mixed friction or wet friction, the friction coefficient is significantly reduced, and there is a hidden danger of brake failure. Significantly reduced service life

At present, some ceramic automobile brake pads on the market use a large amount of ceramic fibers instead of traditional steel fibers. Although their braking comfort performance (including noise, ash falling, and matching with the pair, etc.) has been significantly improved, resin is still used as the main material. Adhesives, which lead to problems such as high-temperature thermal recession, easy cracks and poor high-temperature wear performance at high temperatures

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

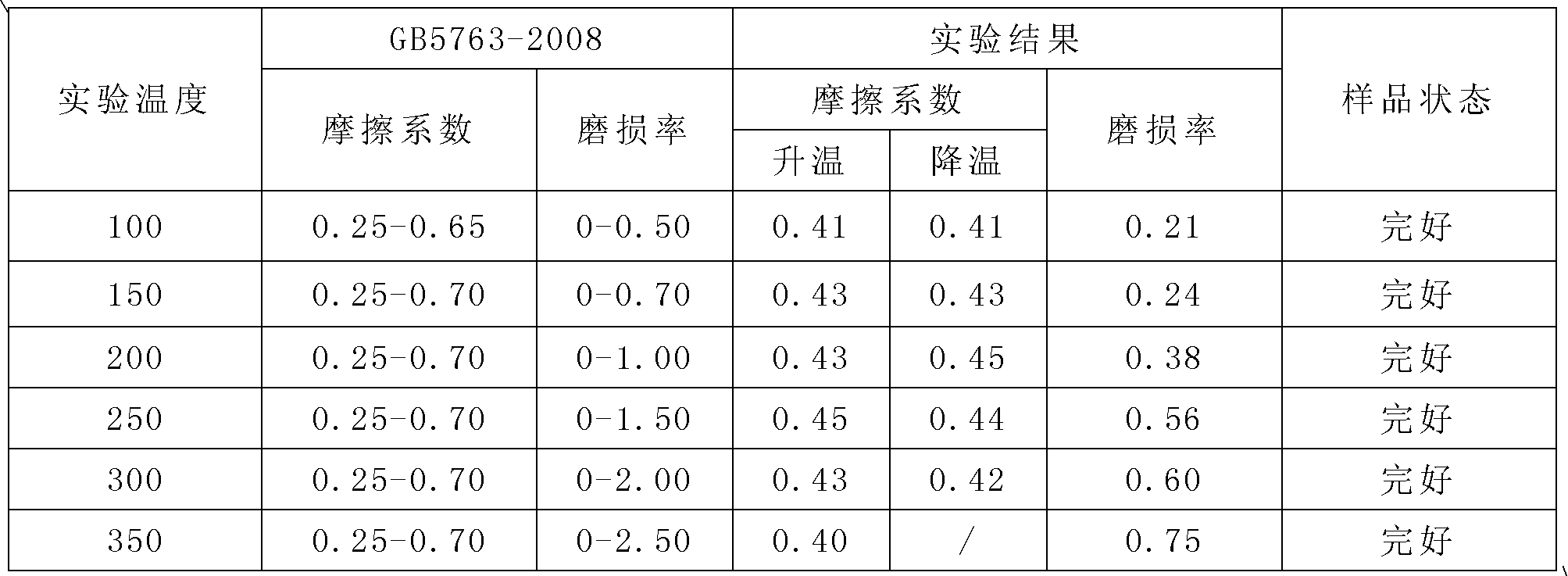

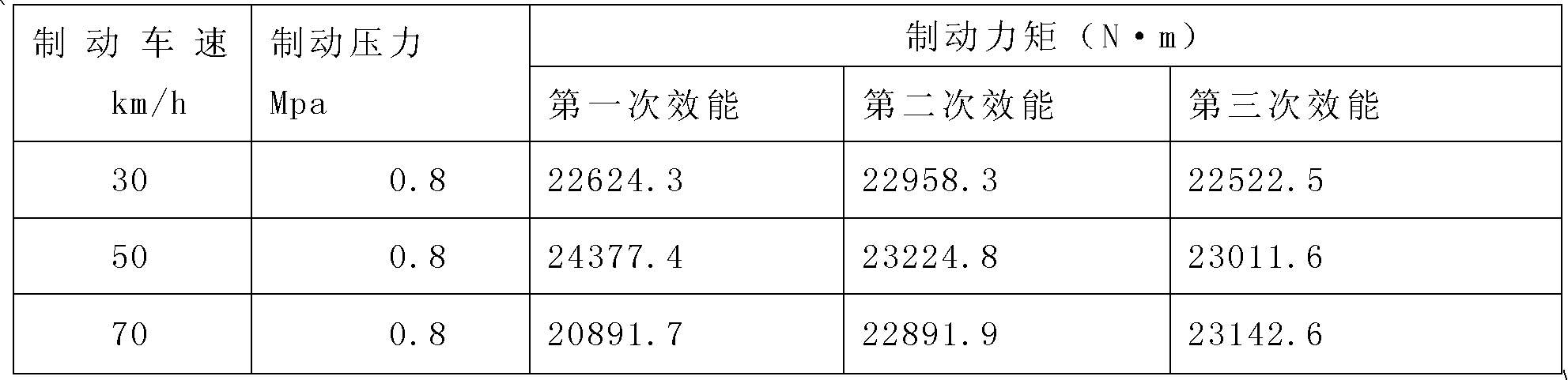

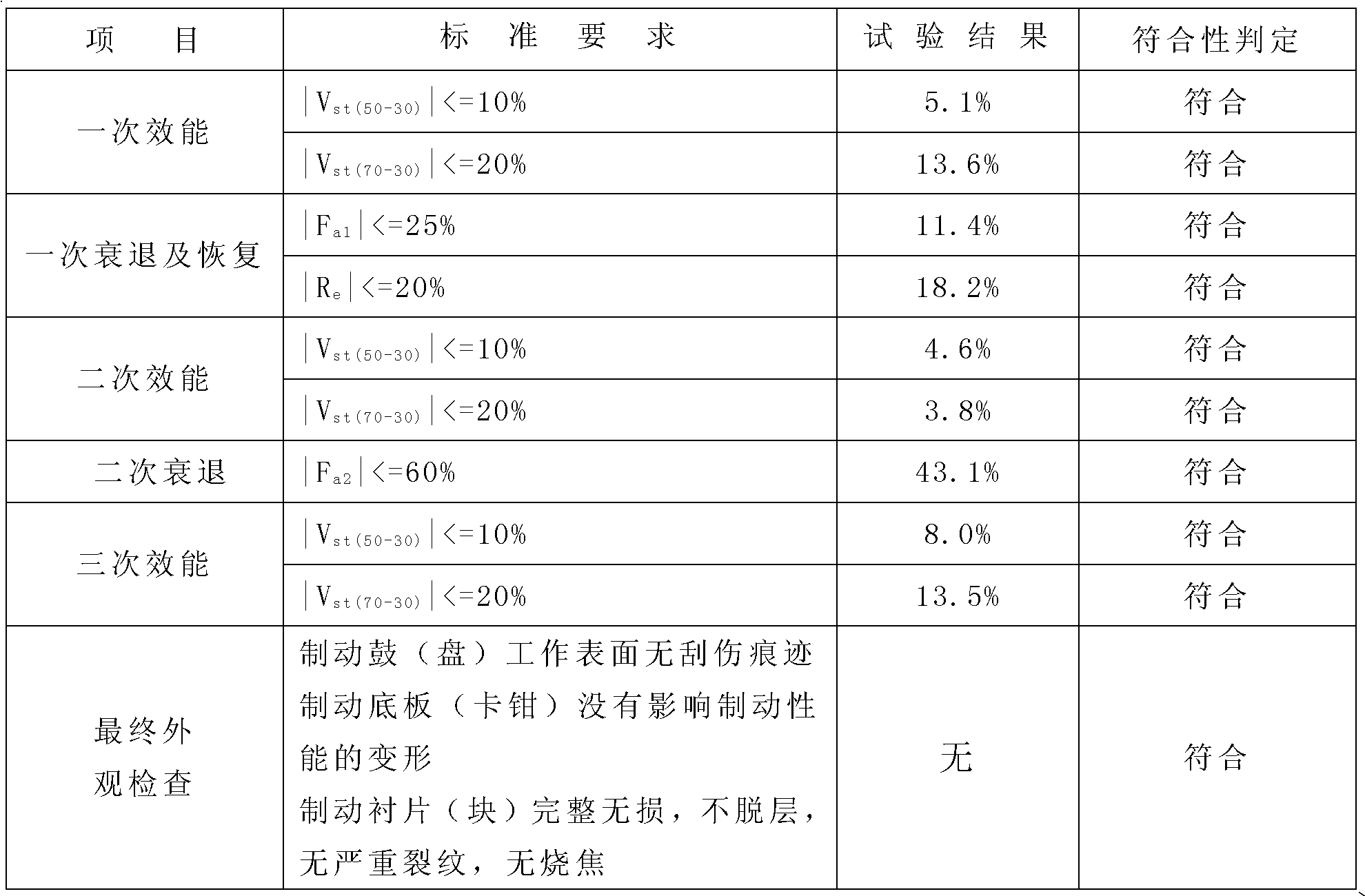

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a semimetal ceramic matrix air disc brake pad of an air disc braking system for heavy-duty freight cars and a production method thereof, wherein the production flow is as follows: sequentially weighing and putting 10 nonmetal assorted fibre, 35-40 metal fibre, 20 or 25 of friction performance regulator, 15-25 of vitrified bond, 5-10 of elastic toughening agent and 10 of filler into a high-speed mixer to mix uniformly, then carrying out pressing and thermocuring treatment according to a dry once-through molding technique of the traditional resin matrix friction materials, finally machining, ceramic processing, inspecting and packaging. The semimetal ceramic matrix air disc brake pad manufactured according to the technique has large braking torque, comfortable emergency braking, small heat fading and simple production technology, is environmental friendly, is particularly suitable for air disc brakes of the heavy-duty freight cars, and has wide market prospect.

Description

technical field The invention relates to an air pressure disc brake pad, in particular to a semi-metal ceramic based brake pad used in an air pressure disc brake system of a heavy-duty truck, and also relates to a preparation method of the brake pad. Background technique From a technical point of view, 1. Due to its structural characteristics, the heat generated by drum brakes is difficult to dissipate during work. Because most of the brake discs of pressure disc brakes are exposed to the air, heat exchange is easy, and the temperature rises during work. Lower, less thermal recession. 2. When the required braking torque is the same, the pneumatic disc brake has a much smaller overall size than the drum brake. Therefore, it brings convenience to the layout of the whole vehicle; and because its mass, especially the mass of the rotating part, is very small more, and the imbalance is much smaller. It can significantly improve the comfort, smoothness and handling stability of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16D69/02F16D65/12

Inventor 刘伯威贺云果刘咏李度成

Owner HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com