Strong magnetic film medium and preparation method thereof

A strong magnetic, thin film technology, applied in the application of magnetic film to substrate, magnetic layer, cathode sputtering application, etc., can solve the problems of complex process and high cost, achieve simple process, good magnetic field direction, small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

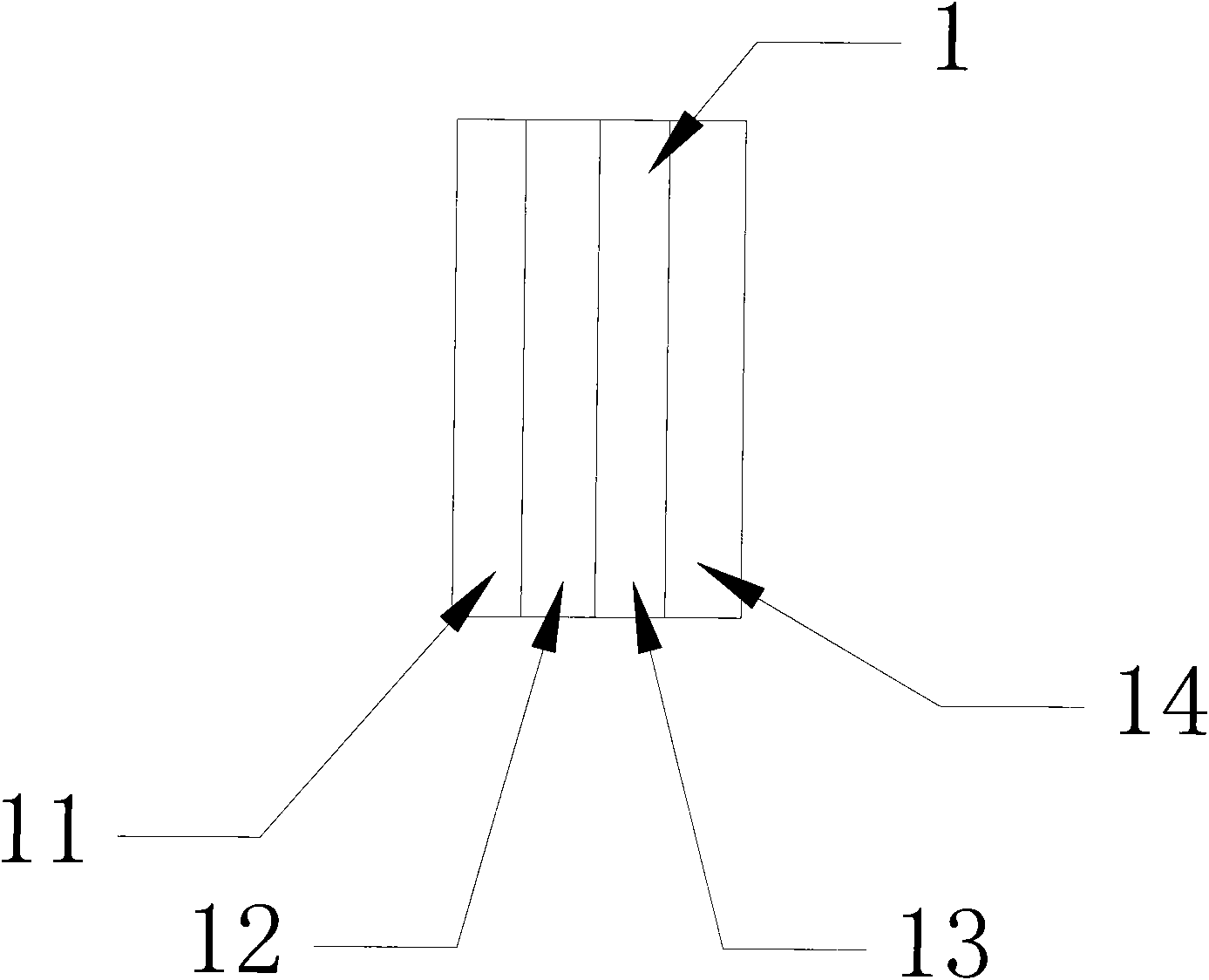

[0018] First prepare a clean and dry Si substrate 11; then cover a mask plate (not shown) on the surface of the Si substrate 11 and press it tightly. The background vacuum of the system is better than 1×10 -4 Pa, heat the Si substrate to 11 to 200-500°C, and the working pressure is 0.2-5Pa; grow Ti, Cr, Ta, Mo, etc. step by step by magnetron sputtering, electron beam evaporation or pulsed laser deposition. The buffer layer 12 of the film, the permanent magnet film 13 of NdFeB, SmCo, AlNiCo, etc. and keep it warm for 1 hour; then raise the temperature to 550-800°C for secondary annealing; grow SiO when cooling to room temperature 2 , SiN, Cr, Ta and other thin-film protective layers 14; finally, use a magnetizer to magnetize and magnetize the thin-film medium.

Embodiment 2

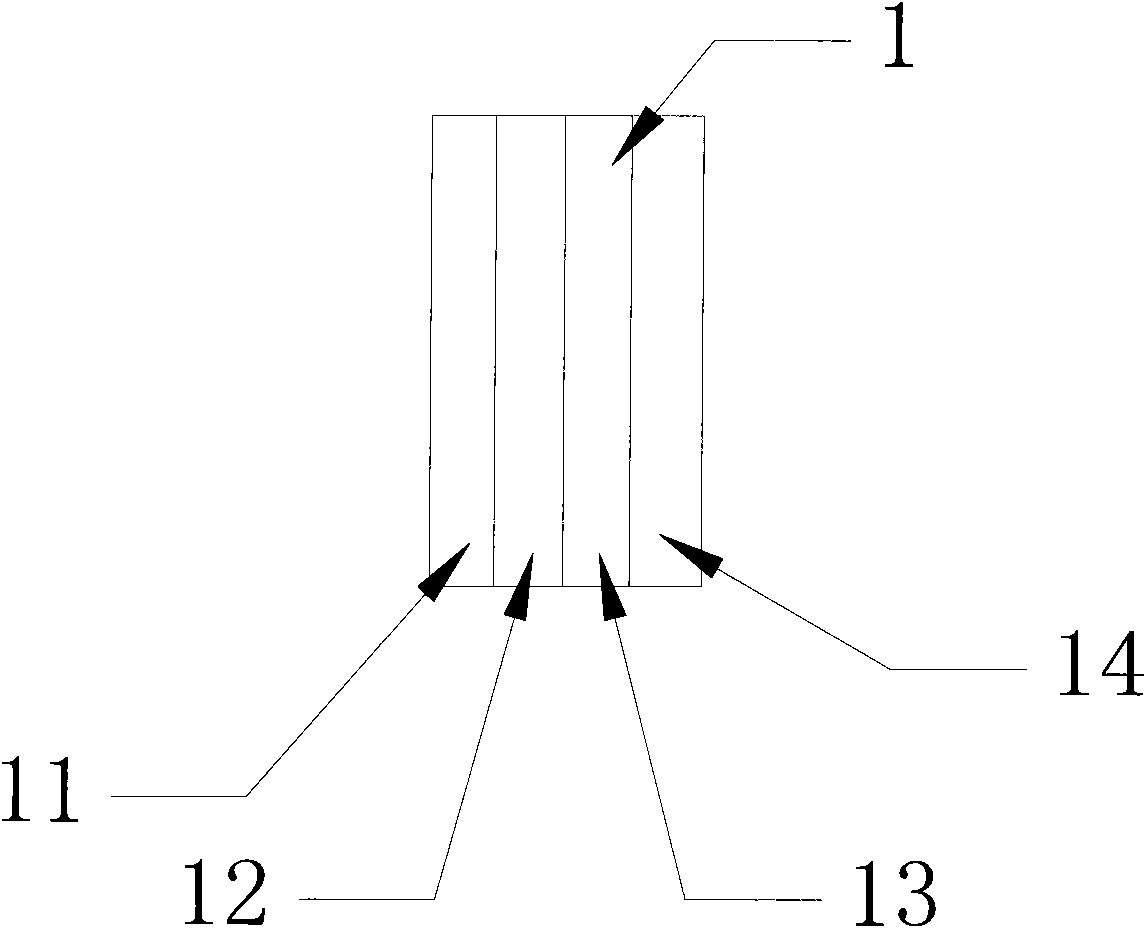

[0020] First prepare a clean and dry Si substrate 11; then grow a buffer layer 12 and a permanent magnetic film 13 on the Si substrate 11 under vacuum conditions, heat it up to 550-800° C. for secondary annealing after 1 hour of heat preservation; then cool to Growth of SiO at room temperature 2 , SiN, Cr, Ta and other thin-film protective layers 14; then use laser ablation of the thin film to obtain laminated thin films with different geometric shapes; finally use a magnetizer to magnetize and magnetize the thin-film medium.

[0021] In summary, the present invention proposes a ferromagnetic thin film medium and a preparation method thereof. The permanent magnet thin film is directly grown by using a mask plate or the permanent magnet thin film is grown and then the thin film is ablated by a laser, and then magnetized and magnetized to obtain a thin film medium. The thin film medium obtained by this scheme has a small volume, and the size reaches the micron level; the magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com