Method for manufacturing linear polyethylenimine (pei) for transfection purpose and linear pei obtained with such method

A linear, transfection technology, applied in other methods of inserting foreign genetic materials, medical preparations with inactive ingredients, pharmaceutical formulations, etc., can solve problems such as low efficiency and poor PEI efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

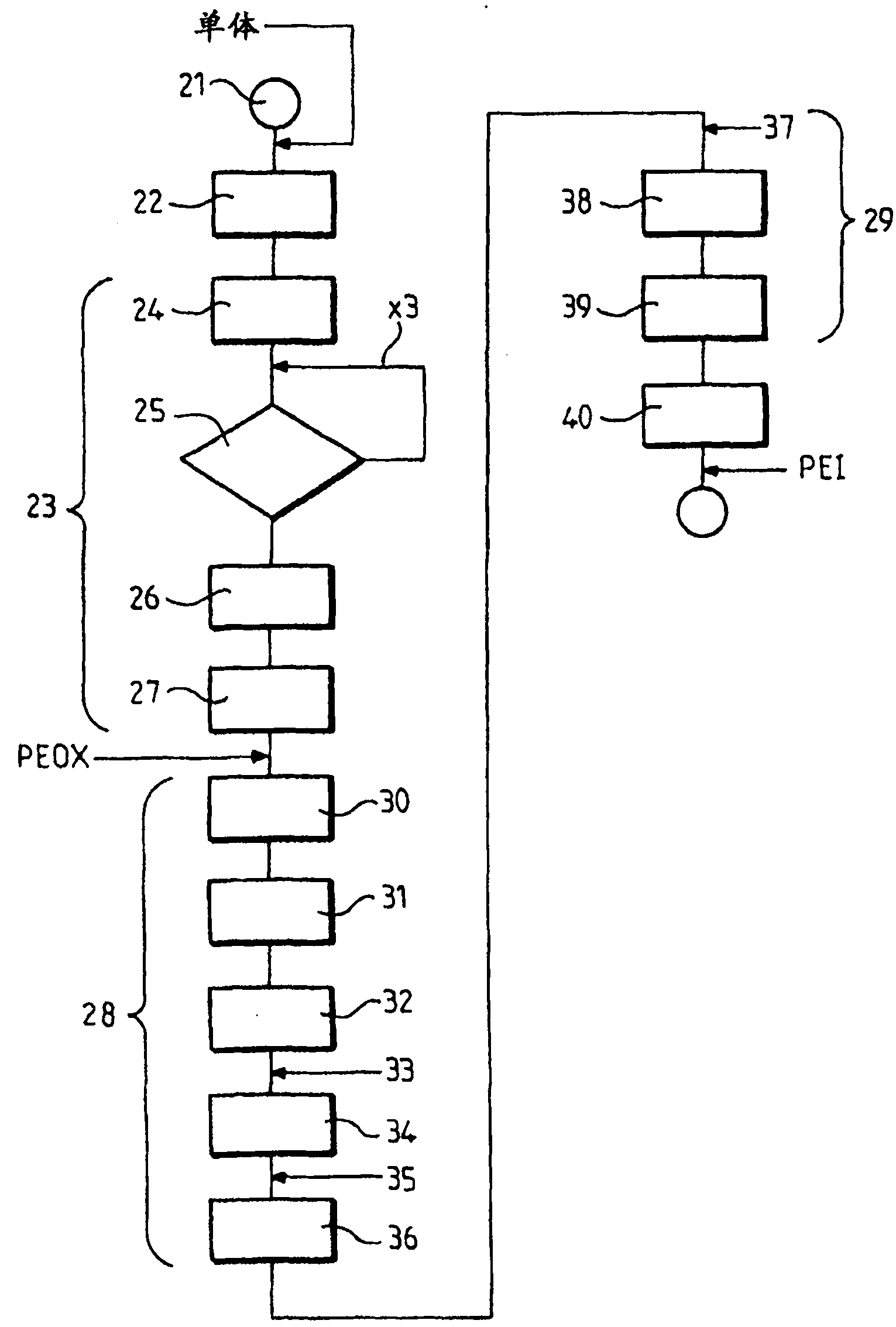

[0042] In a first embodiment (of GMP quality) of the process according to the invention, 2-ethyl-2-oxazoline (mono Cationic ring-opening polymerization of poly(2-ethyl-2-oxazoline).

[0043] The oxazoline ring forms (see Propagation Step of Ring Opening Polymerization hereafter) and is then attacked by the next monomer.

[0044] This gave a living polymer and the polymerization was terminated by adding water and sodium carbonate.

[0045]

[0046] Oxazoline ring active polymer

[0047] The degree of polymerization is controlled by the monomer / initiator ratio and the yield of the synthesis.

[0048] From the monomer / initiator ratio, the theoretical number average molecular weight (Mn) can be calculated. Highly controlled polymerization provides polymers with a defined Mn close to the theoretical Mn and with a low polydispersity index.

[0049] When PEOX molecular weights from 1,000 to 10,000 Da are desired, typical polymerization yields range from 55 to 95% (Hoogenbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com