Method for production of succinic acid

A technology of succinic acid and organic raw materials, applied in recombinant DNA technology, fermentation and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

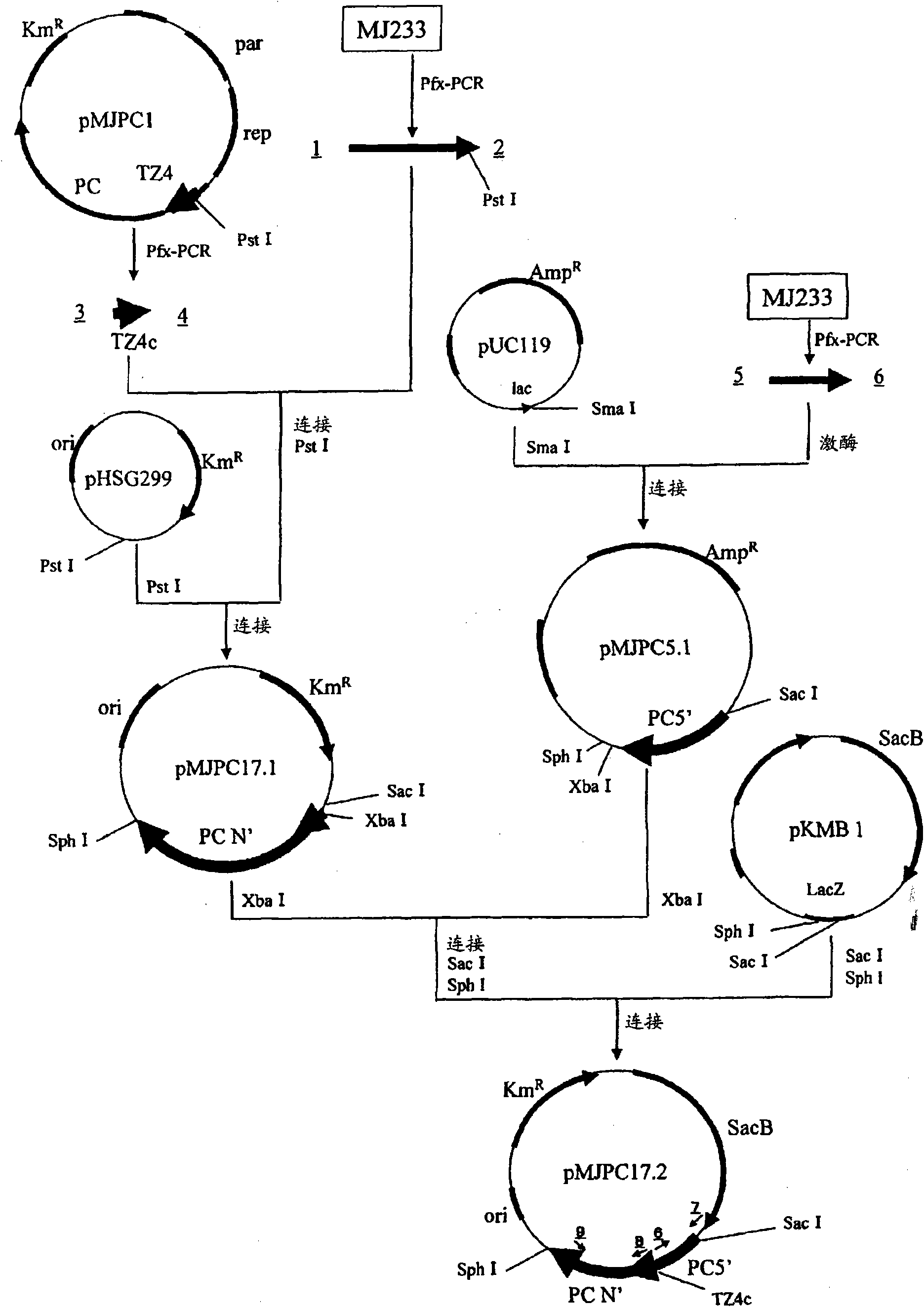

preparation example Construction

[0054] 2. The preparation method of succinic acid

[0055] The method for producing succinic acid according to the present invention is characterized in that succinic acid is generated by reacting the bacterial cells obtained by culturing the above-mentioned bacteria or their processed product with the organic raw material in a reaction liquid containing the organic raw material, and collecting the succinic acid.

[0056] When the above-mentioned bacteria are used for the production of succinic acid, the bacteria cultured on a slant surface with a solid medium such as agar medium can be directly used for the reaction, but it is preferable to use the above-mentioned bacteria cultured in a liquid medium in advance (seed culture). obtained bacteria. As a medium used for seed culture, a common medium used for bacterial culture can be used. For example, a general medium obtained by adding natural nutrient sources such as meat extract, yeast extract, and peptone to a composition co...

Embodiment 1

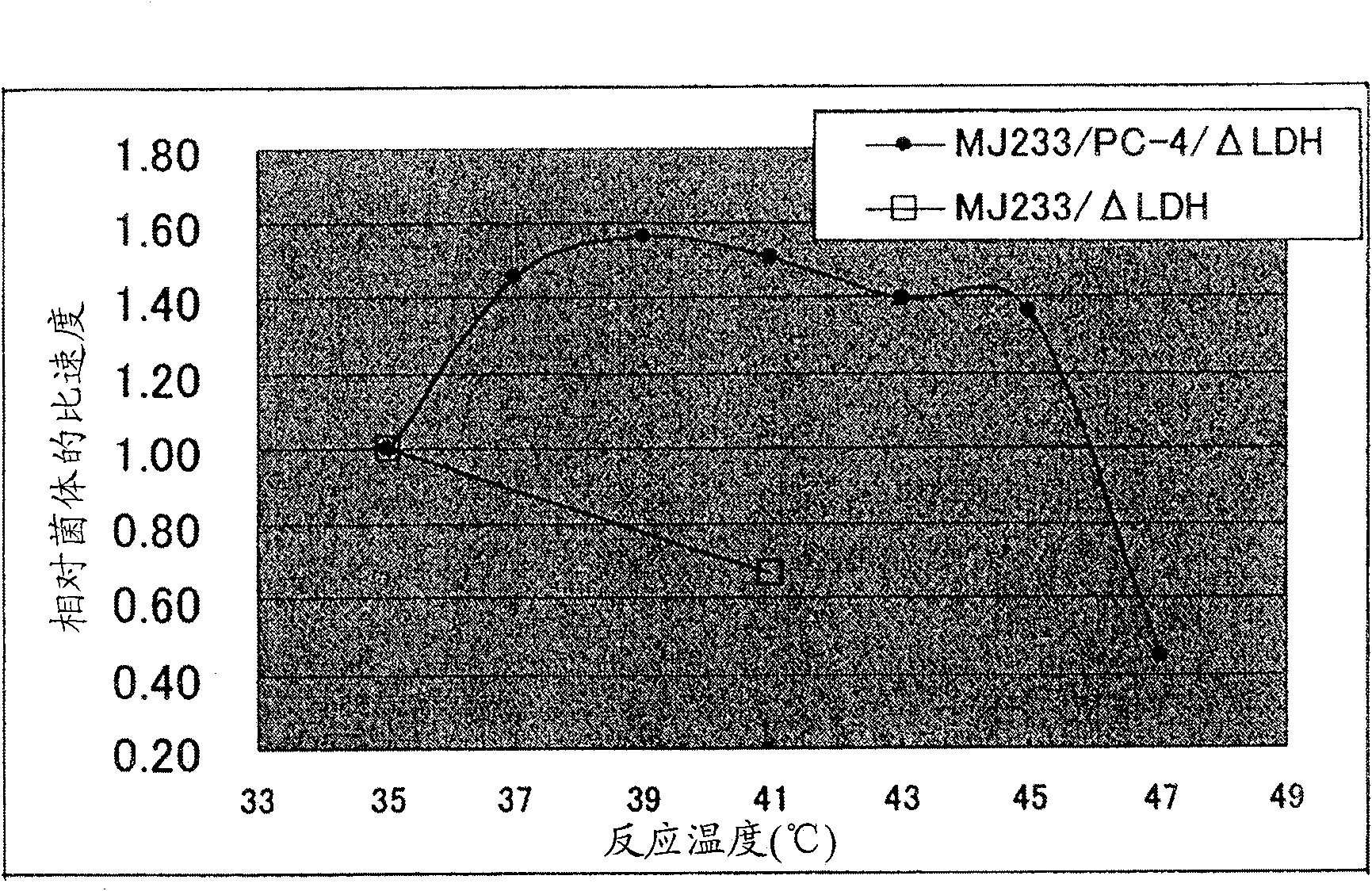

[0088] Evaluation in Fermenter - 1

[0089]

[0090] 100mL culture medium (urea: 4g, ammonium sulfate: 14g, potassium dihydrogen phosphate: 0.5g, dipotassium hydrogen phosphate: 0.5g, magnesium sulfate heptahydrate: 0.5g, ferrous sulfate heptahydrate: 20mg, manganese sulfate Hydrate: 20mg, D-biotin: 200μg, thiamine hydrochloride: 200μg, yeast extract: 5g, casein hydrolyzate: 5g, and distilled water: 1000mL) into a 500mL Erlenmeyer flask, at 120°C Heat sterilize for 20 minutes. Cool it to room temperature, and add 4 mL of 50% glucose aqueous solution that has been sterilized in advance, inoculate the Brevibacterium flavum MJ233 / PC-4 / ΔLDH or MJ233 / ΔLDH constructed above, and seed at 30°C for 16 hours. to cultivate.

[0091]

[0092]Mix 365mL culture medium (ammonium sulfate: 1.0g, potassium dihydrogen phosphate: 1.5g, dipotassium hydrogen phosphate: 1.5g, potassium chloride: 1.67g, magnesium sulfate heptahydrate: 0.5g, ferrous sulfate heptahydrate: 40 mg, manganese sulfat...

Embodiment 2

[0100] Evaluation in Fermenter - 2

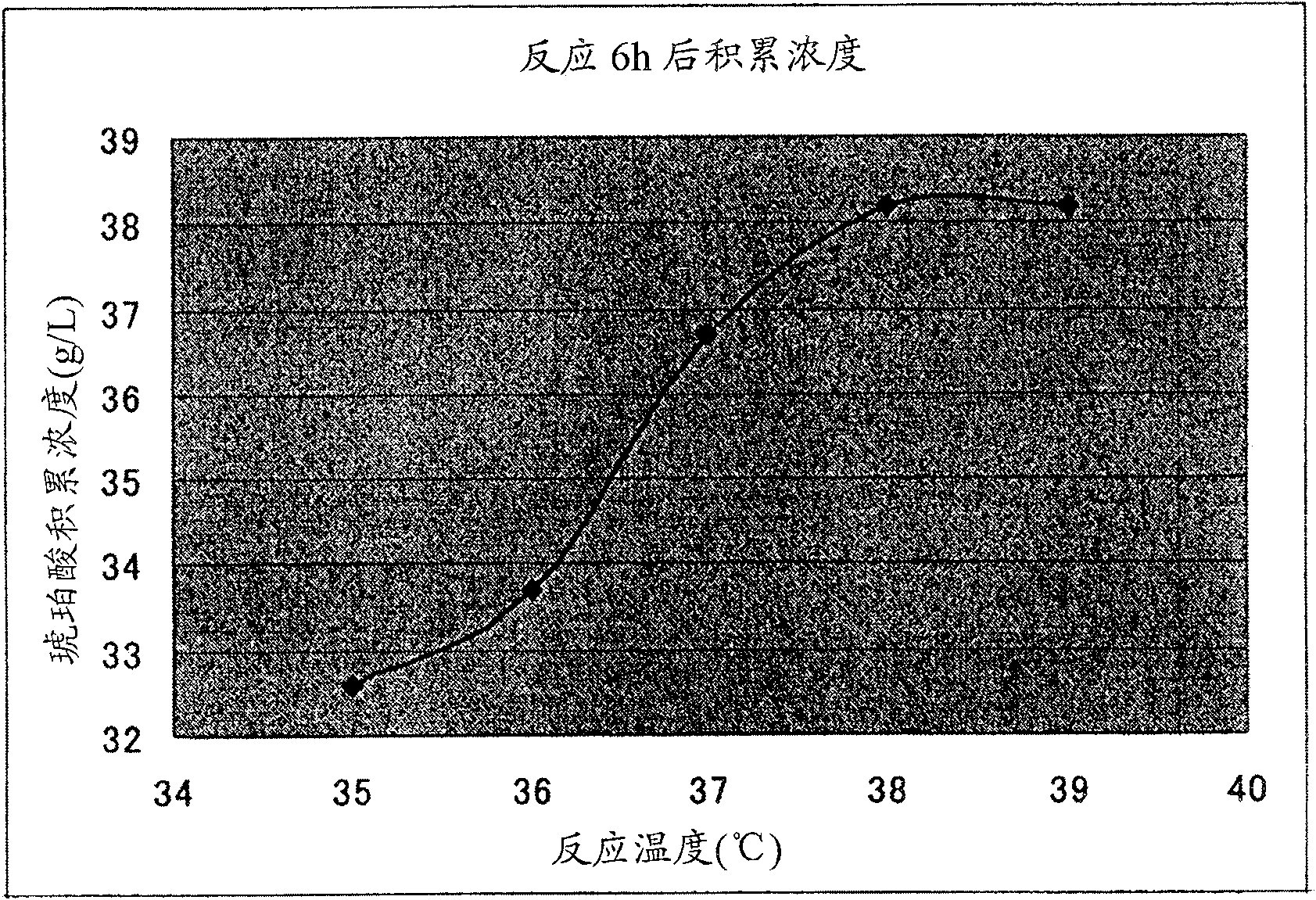

[0101] For the Brevibacterium flavum MJ233 / PC-4 / ΔLDH strain obtained in the same way as the seed culture of Example 1, under the temperature conditions of 35°C, 36°C, 37°C, 38°C and 39°C, follow the same method as in Example 1 Methods, evaluation of succinic acid production cultures was performed. The relationship between the accumulated concentration of succinic acid and the reaction temperature after 6 hours is as follows image 3 shown.

[0102] Depend on image 3 It can be seen that the succinic acid production efficiency of the MJ233 / PC-4 / ΔLDH strain increases rapidly from 37°C or higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com