Method for synthesizing N-isopropylhydroxyla

A technology of isopropylhydroxylamine and propylhydroxylamine salt, applied in the direction of organic chemistry and the like, can solve the problems of complex process, low yield of N-isopropylhydroxylamine, etc., and achieves abundant raw material sources, mild reaction conditions and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

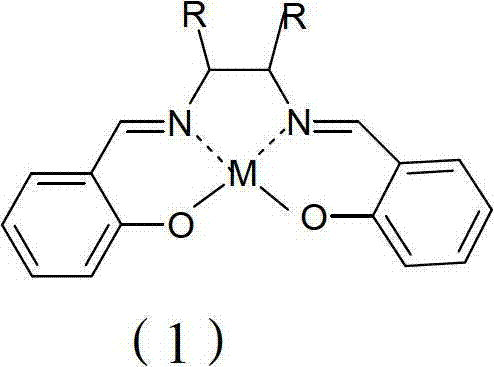

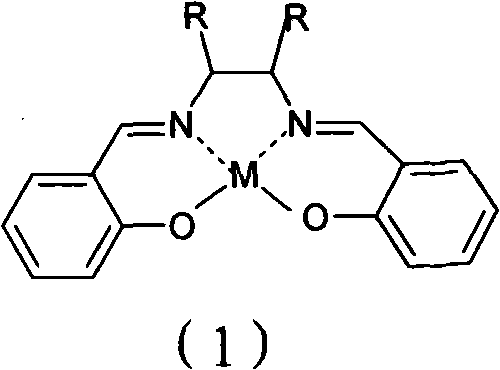

[0025] In a 1000L reactor, add 200Kg of diisopropylamine and 200g of Mn (Salen) catalyst, raise the temperature to 60°C, slowly add 500Kg of 30% aqueous hydrogen peroxide solution dropwise, and complete the dropwise addition in 3 hours. Keep warm for 1h. Then add 214L mass percent concentration and be 37% hydrochloric acid solution, hydrolyze under acidic condition, concentrate, cooling crystallization makes 201Kg isopropyl hydroxylamine hydrochloride; Add 600L methyl tert-butyl Ether and 170Kg concentration are 50% sodium hydroxide aqueous solution, separate and obtain 119Kg of 99% isopropyl hydroxylamine, and yield is 88% (calculated as diisopropylamine).

Embodiment 2

[0027] In a 1000L reactor, add 200Kg of diisopropylamine and 300g of Mn(Salen-Ph) catalyst, raise the temperature to 60°C, slowly add 600Kg of 25% aqueous hydrogen peroxide solution dropwise, dropwise after 4 hours, dropwise Complete and continue to insulate for 1 hour, then add 230L of hydrochloric acid solution with a mass percentage concentration of 37%, hydrolyze, concentrate, and cool to crystallize under acidic conditions to obtain 185Kg isopropyl hydroxylamine hydrochloride; add 600L of isopropyl hydroxylamine hydrochloride Tetrahydrofuran and 150Kg concentration are 50% aqueous sodium hydroxide solution, separate and obtain 89Kg of 99% isopropyl hydroxylamine, and the yield is 67% (calculated as diisopropylamine).

Embodiment 3

[0029] In a 1000L reactor, add 200Kg of diisopropylamine and 800g of Fe(Salen) catalyst, raise the temperature to 60°C, slowly add 300Kg of 50% aqueous hydrogen peroxide dropwise, and complete the dropwise addition in 2.5 hours. Insulate for 1h, then add 236L of 37% hydrochloric acid solution in mass percentage concentration, hydrolyze under acidic conditions, concentrate, cool and crystallize to obtain 195Kg isopropyl hydroxylamine hydrochloride; add 635L water and 145Kg concentration is 50% sodium hydroxide aqueous solution, separates and obtains 840Kg of 15.6% isopropyl hydroxylamine, and yield is 86% (calculated as diisopropylamine).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com