Natural rubber composite material with modified crystal whiskers and preparation method thereof

A technology for natural rubber and composite materials, applied in the field of natural rubber composite materials and their preparation, can solve the problems of low tensile modulus, low tensile properties and wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

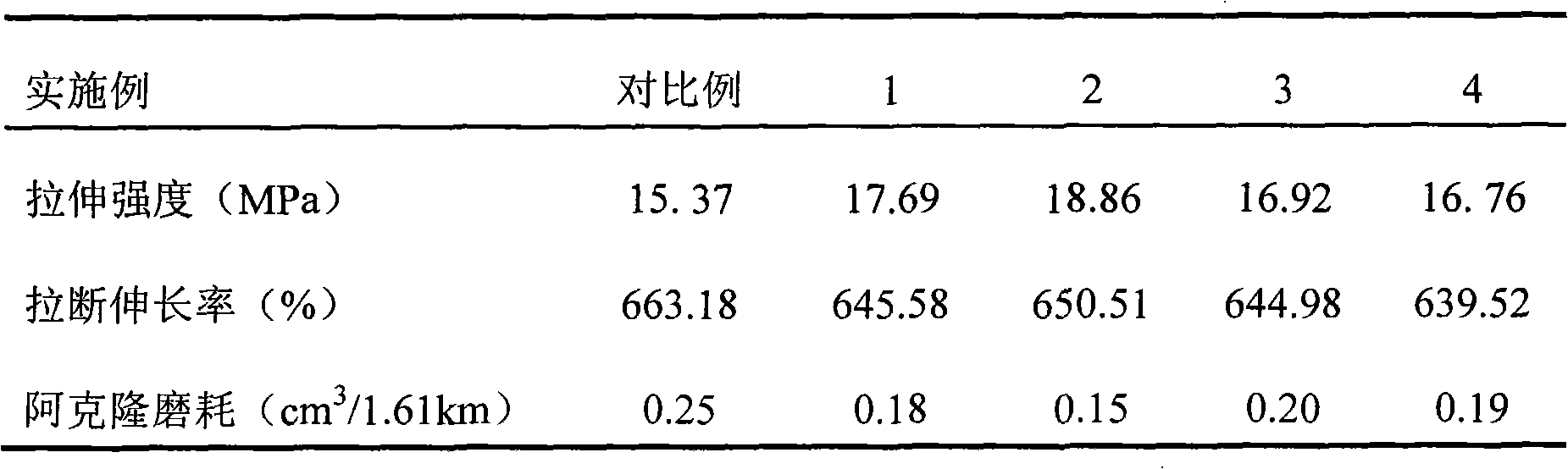

Examples

Embodiment 1

[0035] Surface modification of whiskers

[0036] Mix 190ml of absolute ethanol and 20ml of deionized water to form an aqueous ethanol solution, add 1g of γ-aminopropyltriethoxysilane, place in an ultrasonic processor, and pretreat at 30°C for 10min. Add 40 grams of zinc oxide whiskers, use glacial acetic acid to control the pH of the system to 5, and then ultrasonically treat the mixture at 50°C for 20 minutes, pour it into a watch glass, and dry it in vacuum to obtain modified zinc oxide whiskers.

[0037] Zinc oxide whiskers are T-ZnO products produced by Chengdu Jiaotong University Jingyu Technology Co., Ltd. The average length of the needles is 30 μm, the average diameter of the roots is 4 μm, and the appearance is loose white powder.

[0038] Preparation of modified whisker and natural rubber composites

[0039] 1) Mastication: Put 100 parts of natural rubber on the plate with a roller distance of 0.6 mm, then turn the raw rubber 90 degrees before adding, and repeat the ...

Embodiment 2

[0045] Surface modification of whiskers

[0046] Mix 200ml of absolute ethanol and 55ml of deionized water to make an aqueous ethanol solution, add 2 grams of bis(3-triethoxysilylpropyl)tetrasulfide, place it in an ultrasonic processor, and pretreat at 40°C for 8min . Add 30 grams of calcium sulfate whiskers, use glacial acetic acid to control the pH of the system to 4, ultrasonically treat at 60°C for 15 minutes, pour into a watch glass, and dry in vacuum to obtain modified calcium sulfate whiskers.

[0047] Calcium sulfate whisker is a product of Luoyang Liangdong Africa Metal Material Technology Development Co., Ltd., with an average diameter of 4.5 μm and an average length of 125 μm. It is a whisker-like single crystal with a perfect internal structure.

[0048] Preparation of modified whisker and natural rubber composites

[0049] 1) Mastication: Put 100 parts of natural rubber on the plate with a roll distance of 0.5 mm, then turn the raw rubber 90 degrees before addin...

Embodiment 3

[0055] Surface modification of whiskers

[0056] Mix 250ml of absolute ethanol and 70ml of deionized water to form an aqueous ethanol solution, add 5 grams of γ-glycidyloxypropyltrimethoxysilane, place in an ultrasonic processor, and pretreat at 30°C for 10min. Add 30 grams of magnesium sulfate whiskers, use glacial acetic acid to control the pH value of the system to 6, ultrasonically treat at 50°C for 20 minutes, pour into a watch glass, and vacuum dry to obtain modified magnesium sulfate whiskers.

[0057] The magnesium sulfate whisker is a product of Yingkou Kangru Chemical Co., Ltd. with the brand name WS-1S. It is a white needle-like single crystal fiber with an average diameter of 0.75 μm and an average length of 50 μm.

[0058] Preparation of modified whisker and natural rubber composites

[0059] 1) Mastication: Thin pass 100 parts of natural rubber on the plate at a roller distance of 0.8 mm, then turn the raw rubber 90 degrees before adding, repeat the thin pass 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com