Semiconductor heterostructure, preparation method thereof and semiconductor device

A heterostructure and semiconductor technology, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of complex preparation process and affect the functional characteristics of semiconductor heterostructures, and achieve simple preparation process and good rectification characteristics. , to eliminate the effect of interfacial diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

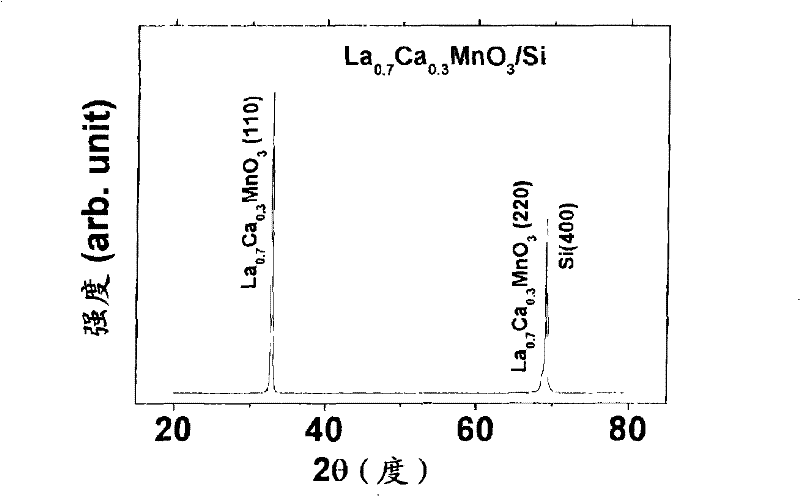

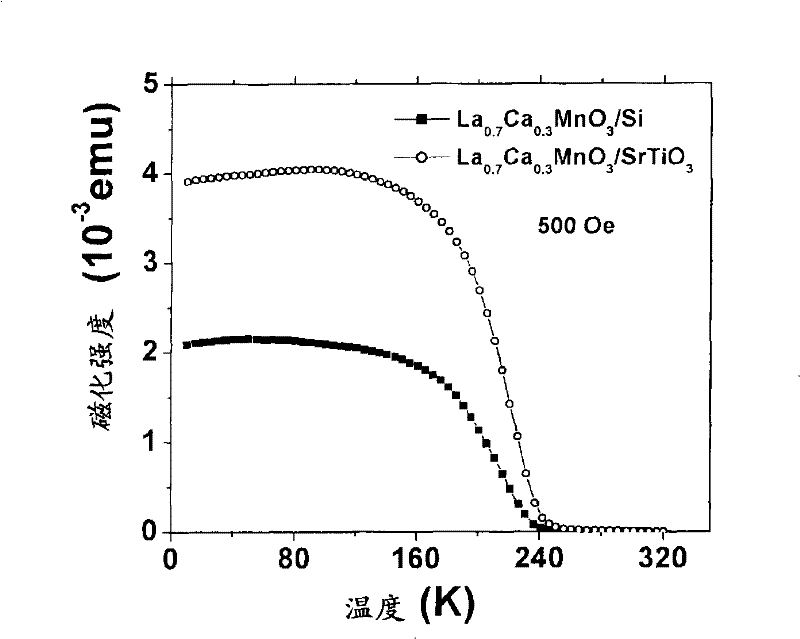

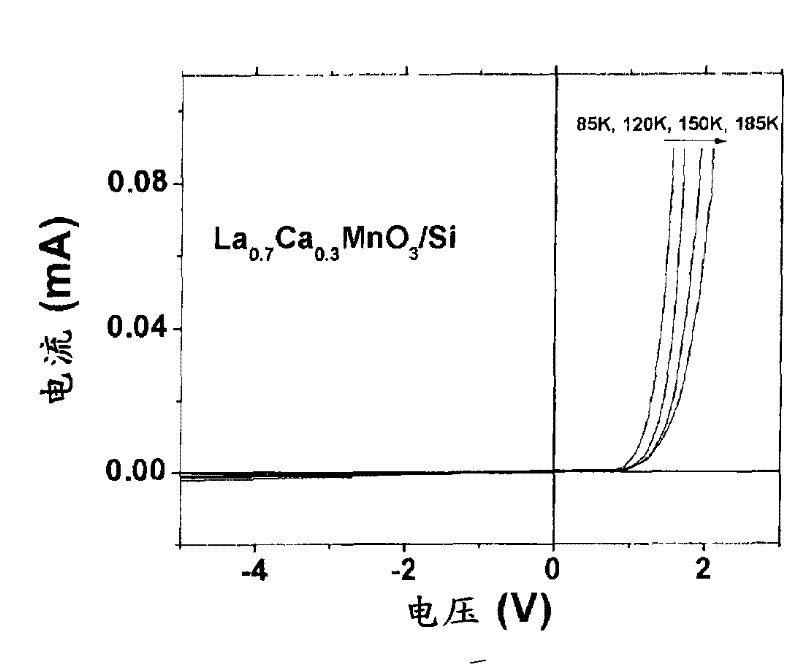

[0050] Example 1 Si / La 0.7 Ca 0.3 MnO 3 Fabrication of semiconductor heterostructures

[0051] La prepared by chemical formula 0.7 Ca 0.3 MnO 3 Perovskite manganese oxide, the specific process is:

[0052] 1) Press La 0.7 Ca 0.3 MnO 3 Chemical formula ingredient, raw material is La 2 o 3 , CaCO 3 , MnCO 3 (CaCO 3 , MnCO 3 Decomposes during calcination, C forms CO 2 followed by airflow). After the proportioned raw materials are fully ground and mixed, they are calcined at 900 degrees Celsius for 24 hours. After taking it out, it was ground and calcined three times under the same conditions, and then sintered at 1350 degrees Celsius for 48 hours to prepare a La with a diameter of 40 mm and a thickness of 5 mm. 0.7 Ca 0.3 MnO 3 target.

[0053] 2) Phosphorus-doped n-type single crystal silicon with a resistivity of 6Ω·cm is selected as the substrate, and the single crystal orientation is (100). Before deposition, the silicon substrate is first c...

Embodiment 2

[0059] Example 2 Si / La 0.7 Ba 0.3 MnO 3 Fabrication of semiconductor heterostructures

[0060] La prepared by chemical formula 0.7 Ba 0.3 MnO 3 Perovskite manganese oxide, the specific process is:

[0061] 1) Press La 0.7 Ba 0.3 MnO 3 The chemical formula ingredients, the raw material is La 2 o 3 , BaCO 3 , MnCO 3 (BaCO 3 , MnCO 3 Decomposes during calcination, C forms CO 2 followed by airflow). After fully grinding and mixing the raw materials prepared according to the proportion, calcining at 900 degrees Celsius for 24 hours. After taking it out, it was ground and calcined under the same conditions, repeated three times, and then sintered at 1350 degrees Celsius for 48 hours to prepare a La with a diameter of 40 mm and a thickness of 5 mm. 0.7 Ba 0.3 MnO 3 target.

[0062] 2) Phosphorus-doped n-type single crystal silicon with a resistivity of 6Ω·cm is selected as the substrate, and the single crystal orientation is (100). Before deposition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com