Architectural tile prepared by using Anshan-type iron ore tailings and preparation method thereof

An iron ore tailings, Anshan-style technology, applied in the field of building finishing materials, can solve the problems of undiscovered building finishing material formula and preparation process, and achieve the effects of reducing energy consumption, simple production process and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

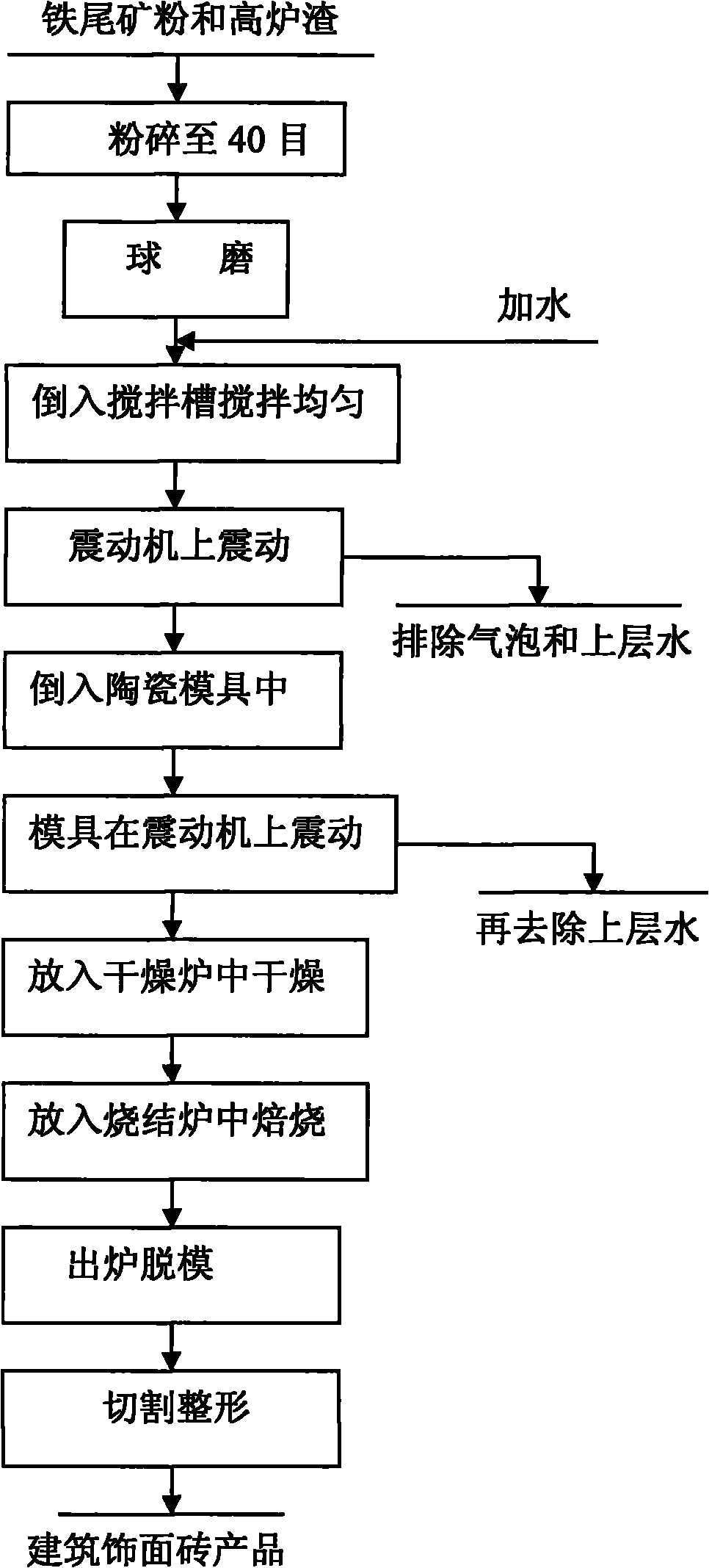

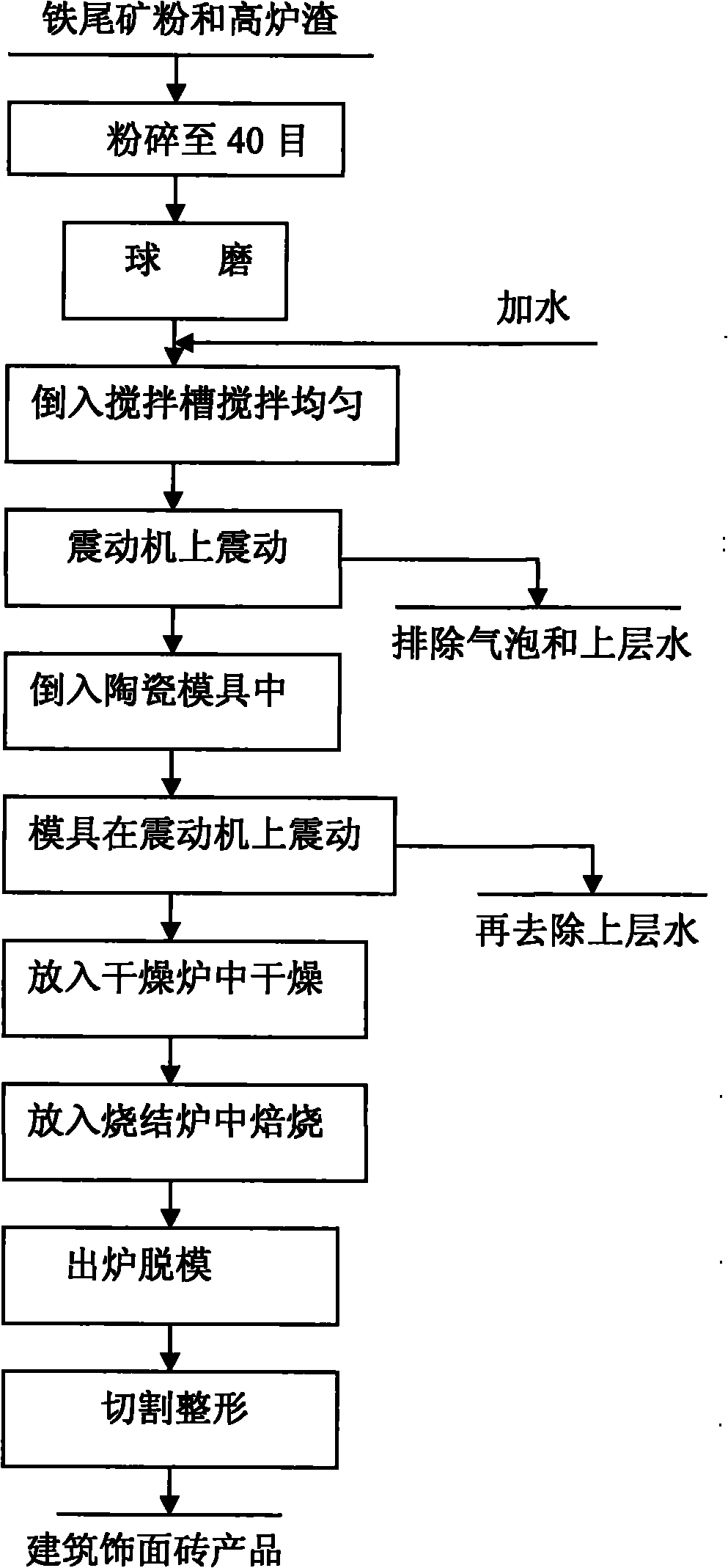

[0056] The method for preparing building facing bricks with Anshan type iron ore tailings comprises the following sequence and steps:

[0057] a. First crush the iron tailings powder and blast furnace slag to below 40 mesh respectively;

[0058] b. By weight percentage, 54Kg iron tailings powder, 25Kg blast furnace slag, 2Kg borax, 0.5Kg anhydrous BaCO 3 , 5Kg magnesite, 1.5Kg potassium feldspar, 5Kg soda ash, 1.2KgTiO 2 , 1.5KgSb 2 o3 Pack into ball mill with 1.3Kg sulfur and mix for 10 hours;

[0059] c. Pour the ground material into the mixing tank, add 48Kg of water according to the ratio of water and material volume 1:2, mix evenly, and adjust it into a uniform thin paste;

[0060] d. Vibrate on a vibrator for 4 hours to remove the air bubbles and remove the upper layer of water;

[0061] e. Pour it into a ceramic mold with a thickness of 30 mm. The mold is shaken on a vibrator for 2 hours, and then the upper layer of water is removed;

[0062] f. Then put the mold a...

Embodiment 2

[0068] The method for preparing building facing bricks with Anshan type iron ore tailings comprises the following sequence and steps:

[0069] a. First crush the iron tailings powder and blast furnace slag to below 40 mesh respectively;

[0070] b. By weight percentage, 45Kg iron tailings powder below 40 mesh, 32Kg blast furnace slag, 4Kg borax, and 1Kg anhydrous BaCO 3 , 9Kg magnesite, 2Kg potassium feldspar, 5Kg soda ash, 1Kg TiO 2 , 1KgSb 2 o 3 Pack into ball mill with 1Kg sulfur and mix for 10 hours;

[0071] c. Pour the ground material into the mixing tank, add 50Kg of water according to the ratio of water and material volume 1:2, mix evenly, and adjust it into a uniform thin paste;

[0072] d. Vibrate on a vibrator for 4 hours to remove the air bubbles and remove the upper layer of water;

[0073] e. Pour it into a ceramic mold with a thickness of 30 mm. The mold is shaken on a vibrator for 2 hours, and then the upper layer of water is removed;

[0074] f. Then put...

Embodiment 3

[0080] The method for preparing building facing bricks with Anshan type iron ore tailings comprises the following sequence and steps:

[0081] a. First crush the iron tailings powder and blast furnace slag to below 40 mesh respectively;

[0082] b. By weight percentage, 50Kg iron tailings powder, 28Kg blast furnace slag, 3Kg borax, 0.8Kg anhydrous BaCO 3 , 6Kg magnesite, 1.8Kg potassium feldspar, and 6Kg soda ash were mixed in a ball mill for 10 hours;

[0083] c. Pour the ground material into the mixing tank, add 48Kg of water according to the ratio of water and material volume 1:2, mix evenly, and adjust it into a uniform thin paste;

[0084] d. Vibrate on a vibrator for 4 hours to remove the air bubbles and remove the upper layer of water;

[0085] e. Pour it into a ceramic mold with a thickness of 30 mm. The mold is shaken on a vibrator for 2 hours, and then the upper layer of water is removed;

[0086] f. Then put the mold and materials together in a drying oven at 85°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com