Purification process for preparing C4 materials for isobutene by C4 linear chain olefin skeleton isomerism

A technology for purifying processes and materials, which is applied in the petrochemical field and can solve problems such as poor selectivity, poisoning and deactivation of heterogeneous catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

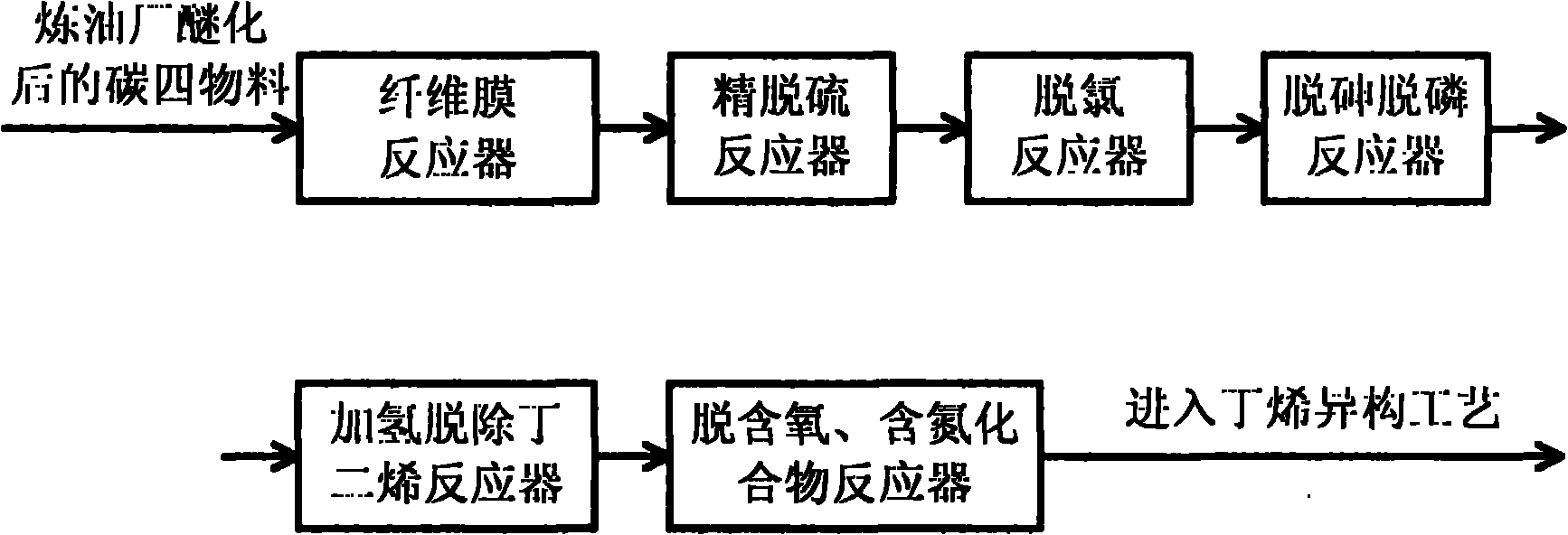

[0082] Example 1 Purification process of C4 material after etherification in refinery

[0083] This embodiment provides a purification process for C4 material after etherification in a refinery, and its process is as follows figure 1 shown. The flow rate of the C4 material after etherification in the refinery used in this embodiment is 12 tons / h, the concentration of n-butene is about 47%, and there is no carbonyl sulfide. Its main composition is shown in Table 2.

[0084] Table 2

[0085] name

Content / w%

name

content

Propylene

0.01

Total sulfur (calculated as sulfur)

20ppm

2.0

MTBE

70ppm

[0086] name

Content / w%

name

content

40.1

Acetonitrile+propionitrile+NH 3

2ppm

n-butane

8.61

2ppm

1.51

arsenic

40ppb

C 5 +

1.1

h 2 o

300ppm

0.1

...

Embodiment 2

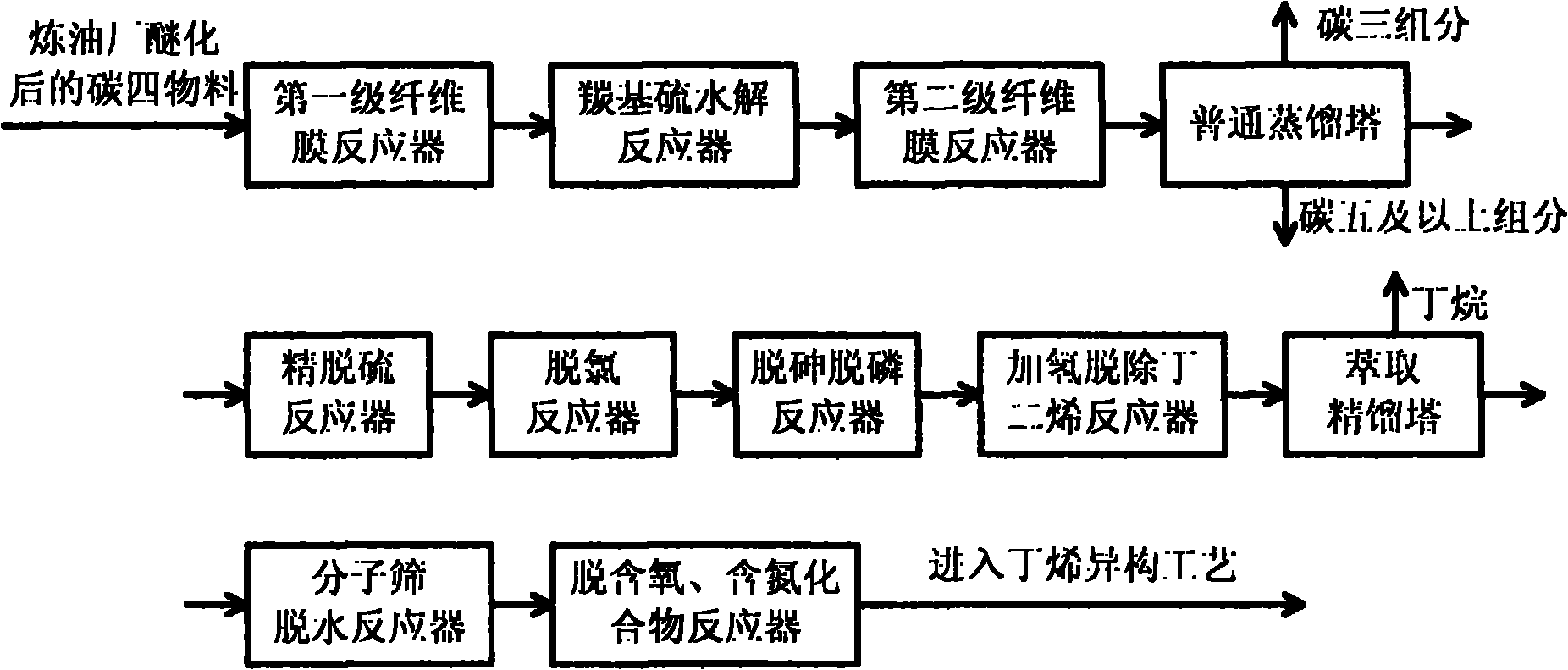

[0096] Example 2 Purification process of C4 material after etherification in refinery

[0097] This embodiment provides a purification process for C4 material after etherification in a refinery, and its process is as follows figure 2 shown. The flow of C4 material after etherification in the refinery used in this embodiment is 25 tons / h, the concentration of n-butene is about 56%, and the content of COS is about 15ppm. The main composition is shown in Table 3.

[0098] table 3

[0099] name

content%

name

Content / w

Propylene

0.1

Total sulfur (calculated as sulfur)

60ppm

3

MTBE

300ppm

30

Acetonitrile+propionitrile+NH 3

5ppm

n-butane

8

3.5ppm

1

arsenic

80ppb

C5+

1

h 2 o

500ppm

0.6

COS

15ppm

Butadiene

0.1

margin

[...

Embodiment 3

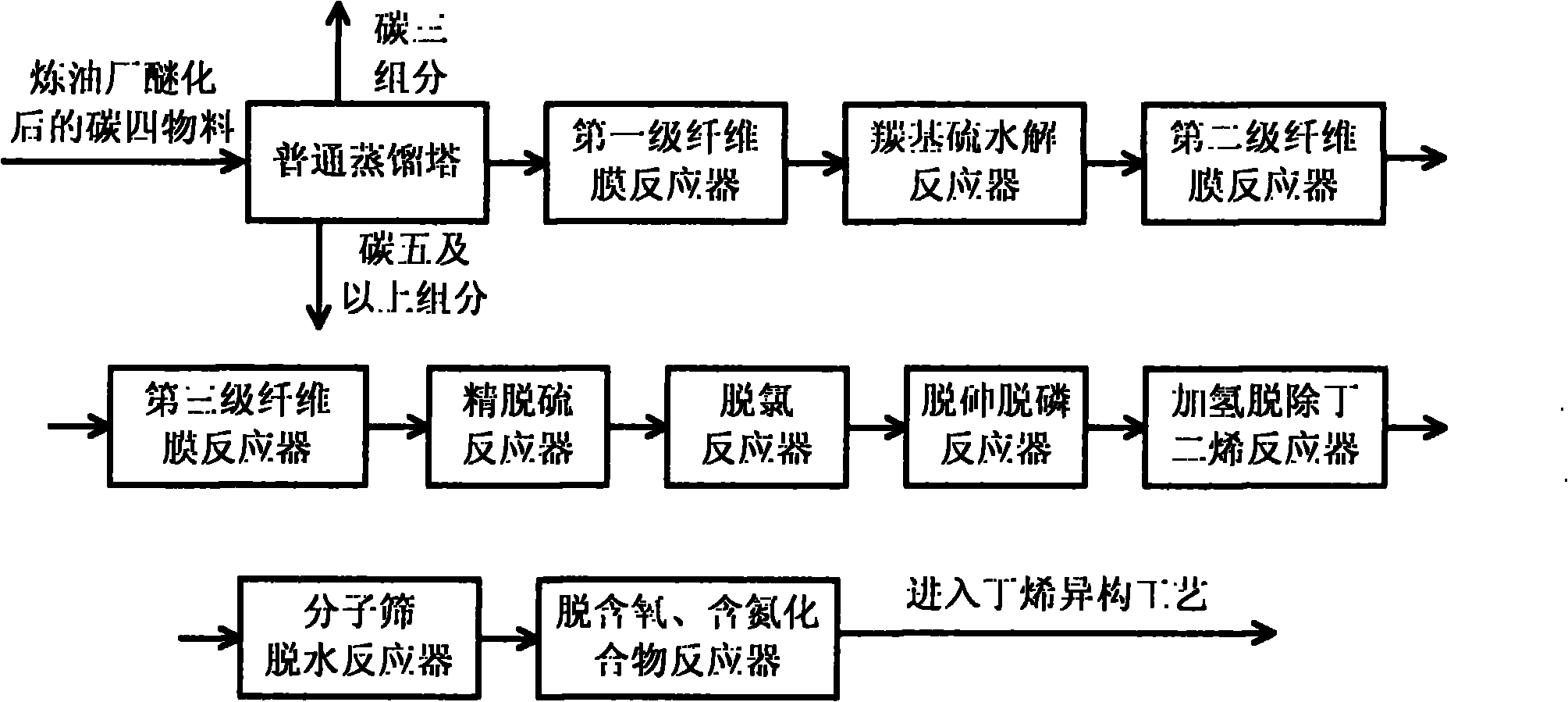

[0114] Example 3 Purification process of C4 material after etherification in refinery

[0115] This embodiment provides a purification process for C4 material after etherification in a refinery, and its process is as follows image 3 shown. The flow rate of the C4 material after etherification in the refinery used in this embodiment is 35 tons / h, the n-butene is about 48%, and the COS content is about 7ppm. The main composition is shown in Table 4.

[0116] Table 4

[0117] Element

wt%

carbon two

0.226

[0118] Element

wt%

1.316

Propylene

0.7965

35.877

n-butane

11.238

margin

2.2105

carbon five

0.438

Butadiene

0.203

other

0.4925

total sulfur

55.40ppm

chlorine

3.7ppm

150ppb

h 2 o

500ppm

[0119] The purification process of the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com