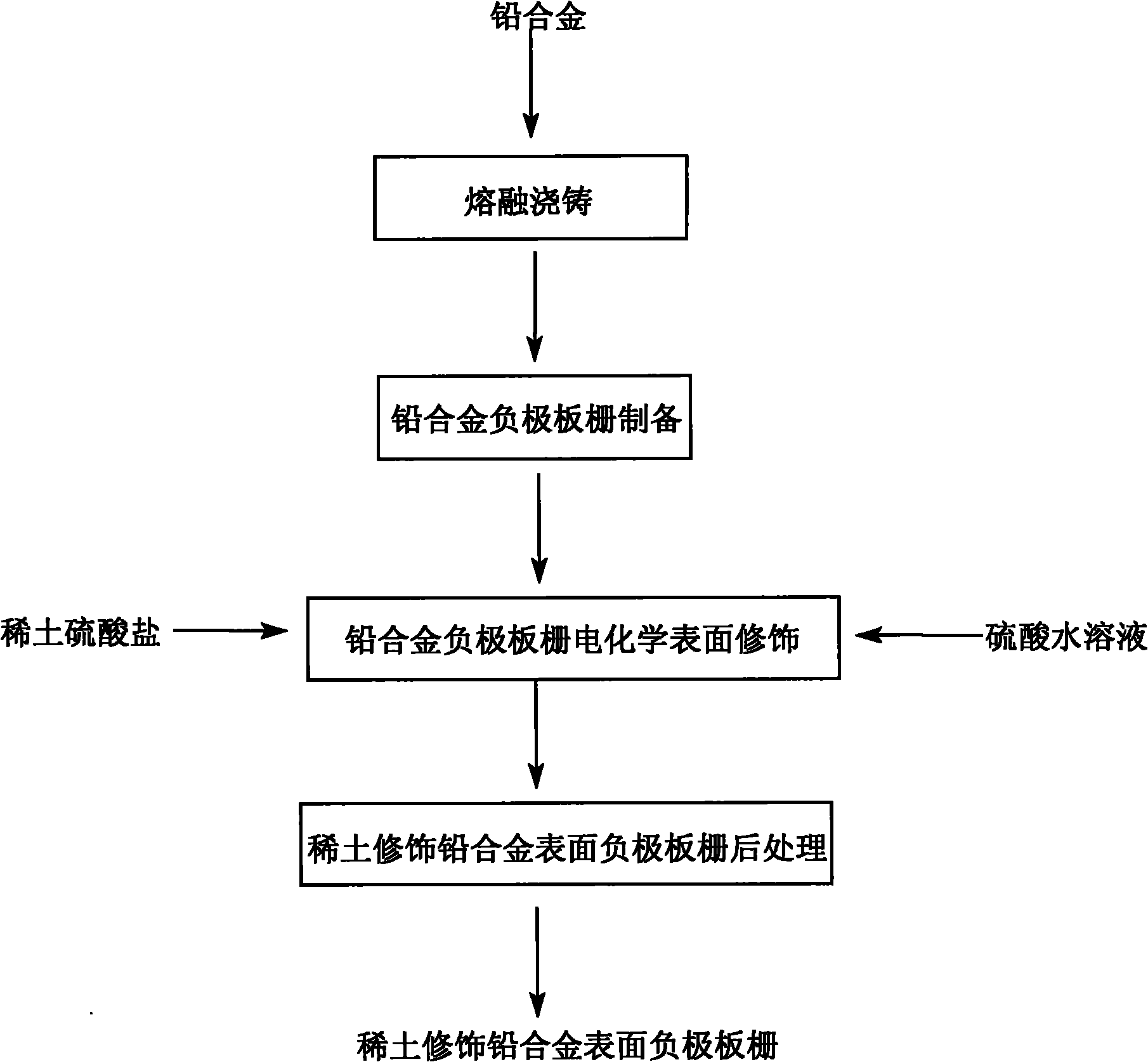

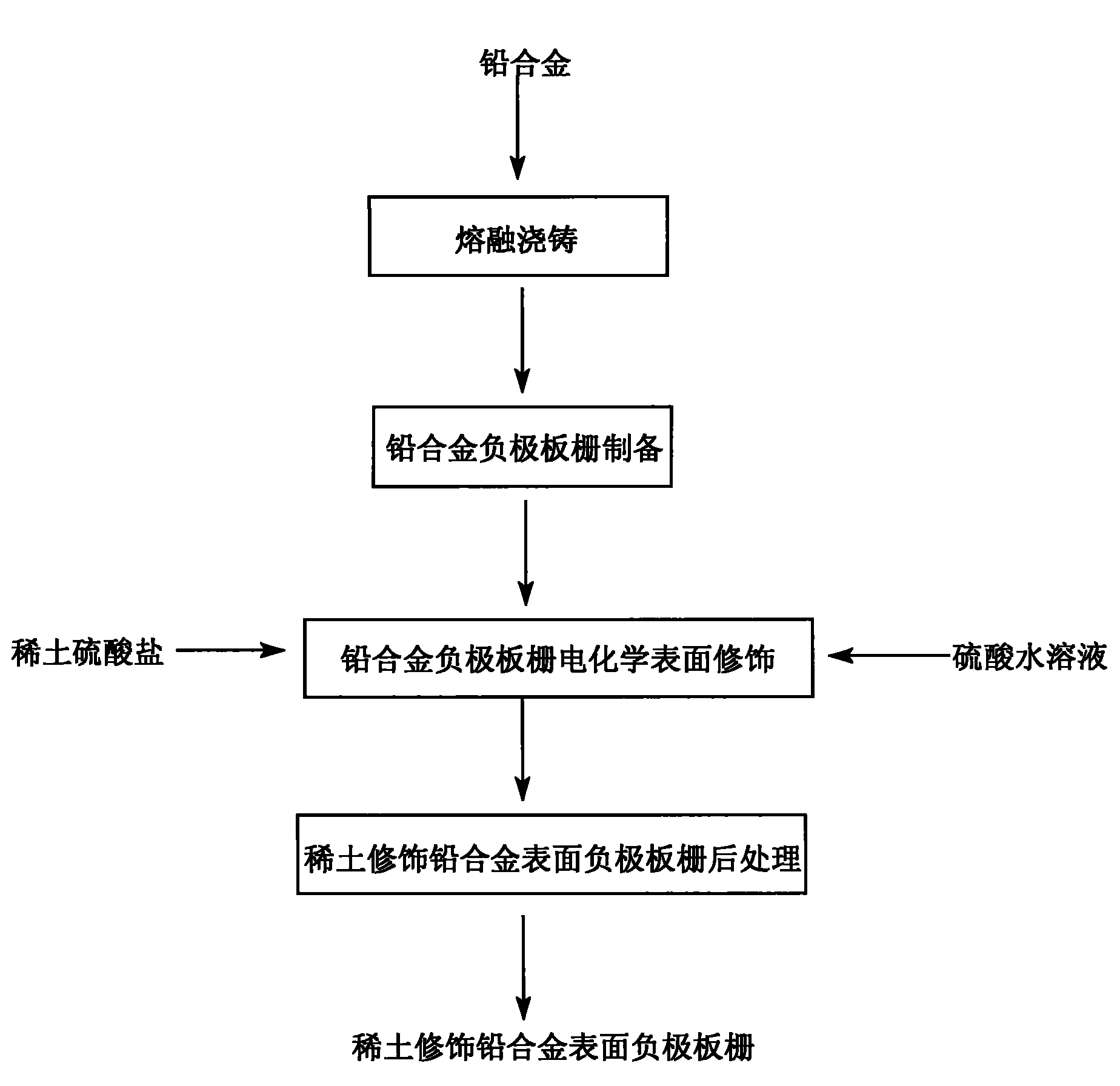

Method for preparing negative grid of lead storage battery

A lead-acid battery and negative plate technology, which is applied in the field of electrode material preparation, can solve the problems of high preparation cost, high technical requirements and high preparation cost of rare earth metals, and achieves the advantages of adjustable micro-domain structure, safe and reliable process, and convenient operation and control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Preparation of lead-antimony (Pb-Sb) alloy negative electrode grid: first add a certain amount of lead and one-third of the mass of antimony (broken into pieces in advance) in a lead melting pot, and melt at 330-400 ° C. Then raise the temperature to 500-550°C, wait until the solid phase is completely melted, stir evenly, remove the scum, take it out of the pot, and cast it into a lead-antimony (Pb-Sb) alloy containing 25% antimony. When the lead-antimony (Pb-Sb) alloy is used as the raw material to melt and cast the grid, a certain amount of high-antimony grid alloy is added with lead and melted to form a lead-antimony (Pb-Sb) alloy with a specified antimony content to obtain lead-antimony (Pb-Sb) alloy negative grid;

[0054] 2. Electrochemical surface modification of the lead alloy negative electrode grid: the lead-antimony (Pb-Sb) alloy negative electrode grid obtained in the above step is used as the cathode, and the lead-antimony (Pb-Sb) alloy is used as the an...

Embodiment 2

[0057] 1. Preparation of lead-calcium (Pb-Ca) alloy negative electrode grid: Divide the calcium into several parts, wrap them in paper, put them into small stainless steel baskets with long handles, extend to the bottom of the lead pot and stir until the calcium melts. The reaction of calcium and lead to form a grid alloy is accompanied by obvious sound and light, that is, a lead-calcium (Pb-Ca) grid alloy with a high calcium content is obtained, and the lead-calcium (Pb-Ca) grid alloy is melted and casted as a raw material Made lead-calcium (Pb-Ca) alloy negative electrode grid;

[0058] 2. Electrochemical surface modification of the lead alloy negative electrode grid: the lead-calcium (Pb-Ca) alloy negative electrode grid obtained in the above step is used as the cathode, and the lead-calcium (Pb-Ca) alloy is used as the anode, at 0.06mol / LSm 2 (SO 4 ) 3 and 4.0mol / L H 2 SO 4 In aqueous solution, the operating temperature is 40°C, and the apparent operating current densi...

Embodiment 3

[0061] 1. Preparation of lead-calcium-tin-aluminum (Pb-Ca-Sn-Al) alloy negative electrode grid: first heat and melt lead in a lead-melting pot, the temperature does not exceed 550°C, then add tin (Sn) and aluminum in sequence Melt (Al) at 550°C and stir well; divide calcium (Ca) into several parts, wrap them in paper, put them in small stainless steel baskets with long handles, and extend to the bottom of the lead pot to stir until the calcium melts. The reaction of calcium and lead to form a grid alloy is accompanied by distinct sound and light. Melting and casting lead-calcium-tin-aluminum (Pb-Ca-Sn-Al) alloy negative grid with lead-calcium-tin-aluminum (Pb-Ca-Sn-Al) alloy as raw material;

[0062] 2. Electrochemical surface modification of lead alloy negative electrode grid: the lead-calcium-tin-aluminum (Pb-Ca-Sn-Al) alloy negative electrode grid obtained in the above step is used as the cathode, and the lead-calcium-tin-aluminum (Pb-Ca -Sn-Al) alloy as the anode, at 0.10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com