Composite particle-loaded article, method for producing the composite particle-loaded article, and method for producing compound using the composite particle-loaded article as chemical synthesis catalyst

A composite particle and manufacturing method technology, which is applied in physical/chemical process catalysts, catalyst activation/preparation, preparation of organic compounds, etc., can solve problems such as unclear structure, inability to obtain pure products and acid anhydrides, and achieve high reactivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0221] 300 g of the carrier obtained in the carrier production reference example was dispersed in 1.0 L of water heated to 90° C., and stirred at 90° C. for 15 minutes. Then, prepare an aqueous solution containing 16.35 g of nickel nitrate hexahydrate and 12 mL of 1.3 mol / L chloroauric acid aqueous solution, heat it to 90° C., add it to the carrier slurry, and continue stirring at 90° C. for 30 minutes to make the nickel and The gold component is insoluble and immobilized on the carrier.

[0222] Next, the supernatant was removed by standing still, washed several times with distilled water, and then filtered. Utilize drier to it after drying at 105 DEG C for 10 hours, in muffle furnace, burn at 450 DEG C in the air for 5 hours, thereby obtain the composite particle loaded material (NiOAu / SiO 2 -Al 2 o 3 -MgO). The Ni / (Ni+Au) atomic ratio of the obtained support was 0.80.

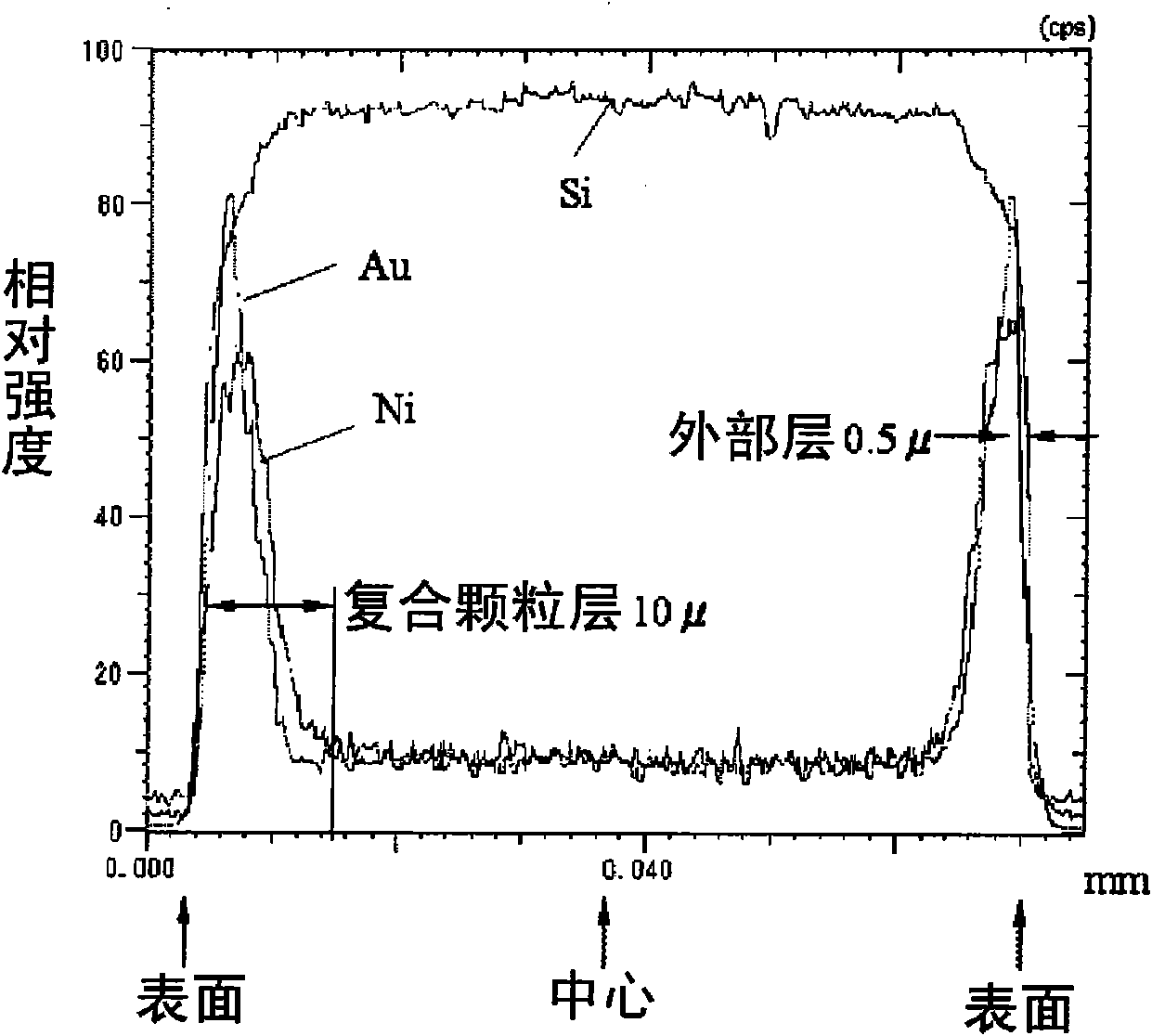

[0223] A sample obtained by embedding the obtained composite particle carrier in a resin and grind...

Embodiment 2

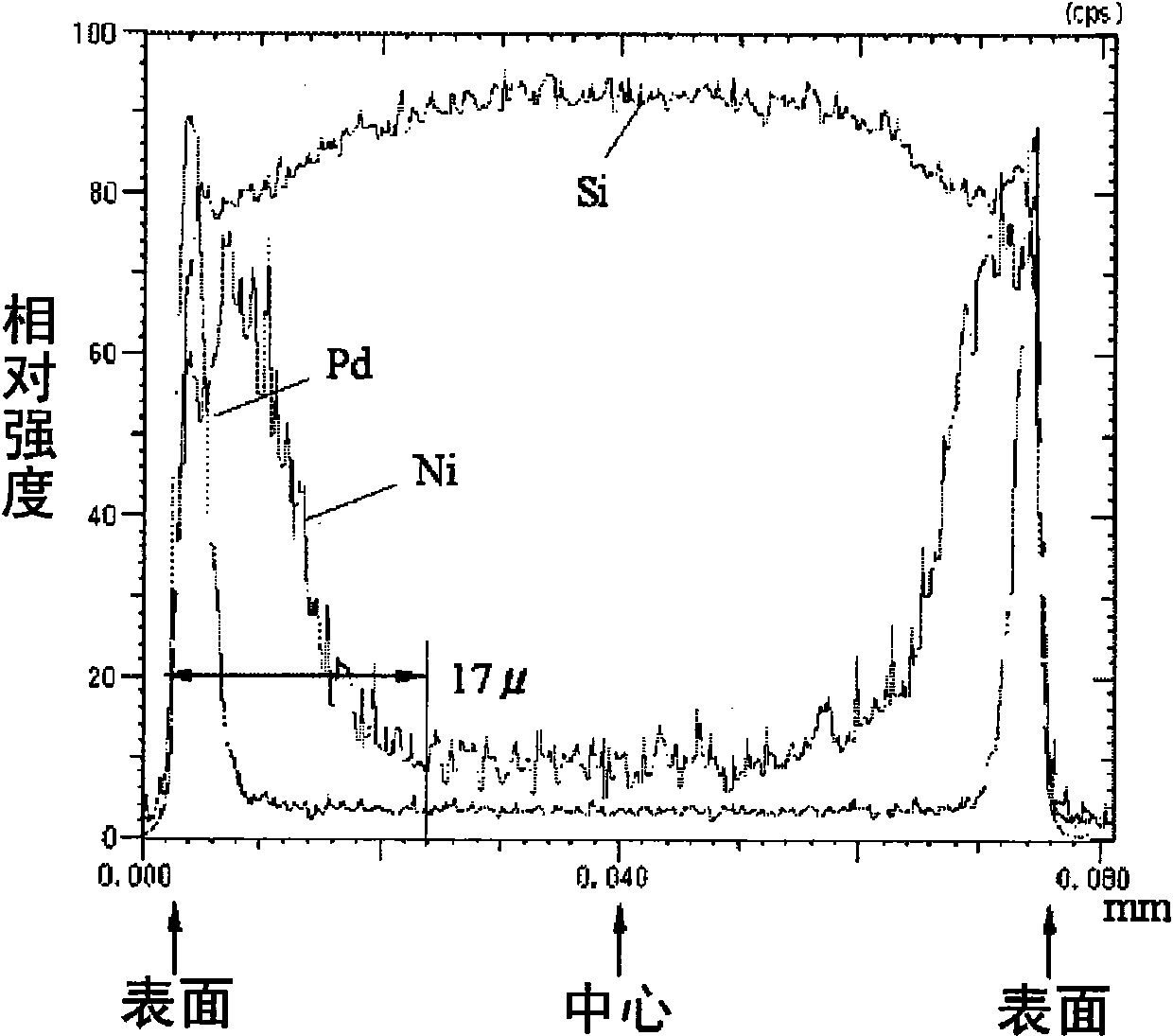

[0230] A 1.0 L aqueous solution in which 2.90 g of magnesium chloride was dissolved was heated to 80° C. and stirred, and 300 g of the carrier obtained in the carrier production reference example was added thereto, and further stirred at 80° C. for 15 minutes. Next, prepare an aqueous solution containing 37.16 g of nickel nitrate hexahydrate and 35 mL of 2.0 mol / L palladium chloride aqueous solution, add it to the above-mentioned carrier slurry after heating to 80° C., and continue stirring at 80° C. for 30 minutes to make nickel and palladium The components are insoluble and immobilized on the carrier.

[0231] Next, the supernatant was removed by standing still, washed several times with distilled water, and then filtered. After drying this at 105 degreeC for 10 hours, it baked at 500 degreeC in air for 5 hours. Then, the resulting load was subjected to a reduction treatment at room temperature in a hydrogen atmosphere for 2 hours, thereby obtaining a composite particle loa...

Embodiment 3

[0236] A 1.0 L aqueous solution in which 3.66 g of aluminum nitrate 9 hydrate was dissolved was heated to 80° C. and stirred, and 300 g of the carrier obtained in the carrier production reference example was added thereto, and further stirred at 80° C. for 10 minutes. Then prepare the aqueous solution containing 25.78g nickel nitrate hexahydrate and 37mL 1.3mol / L chloroauric acid aqueous solution, add in the above-mentioned carrier slurry after being heated to 80 ℃, continue to stir 15 minutes at 80 ℃, make nickel and gold The components are insoluble and immobilized on the carrier.

[0237] Next, the supernatant was removed by standing still, washed several times with distilled water, and then filtered. After drying it at 105°C for 10 hours, it was fired at 400°C in air for 5 hours to obtain a NiOAu / SiO composite particle loaded with 2.20% by mass of nickel and 1.96% by mass of gold. 2 -Al 2 o 3 -MgO). The Ni / (Ni+Au) atomic ratio of the obtained support was 0.79.

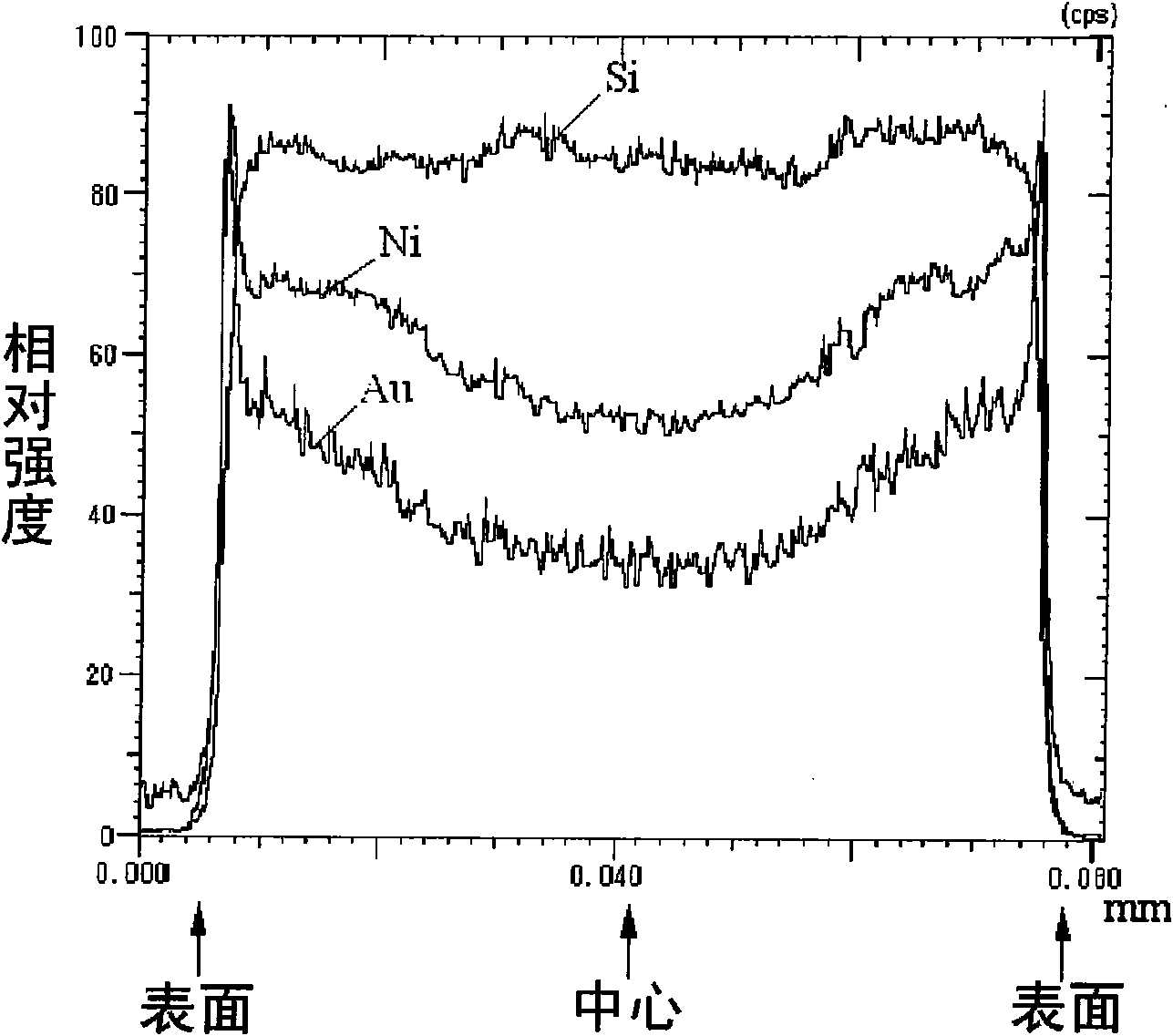

[0238...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com