Zinc oxide light-emitting component and preparation method thereof

A light-emitting element, zinc oxide technology, applied in chemical instruments and methods, light-emitting materials, etc., can solve the problems of low luminous efficiency and weak luminous brightness, and achieve the effects of high ultraviolet luminous intensity, low cost, and enhanced spontaneous radiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The ZnO film was prepared by the sol-gel method, and then a metal silver layer with a thickness of 2nm was deposited on the surface of the film by magnetron sputtering equipment, and then the ZnO film with the silver layer was placed in a vacuum of 1×10 -3 Under a vacuum environment of Pa, annealing treatment is performed at a temperature of 300° C. for 30 minutes, and finally cooled to room temperature to obtain a zinc oxide light-emitting element with a silver layer of a micro-nano structure formed on the surface.

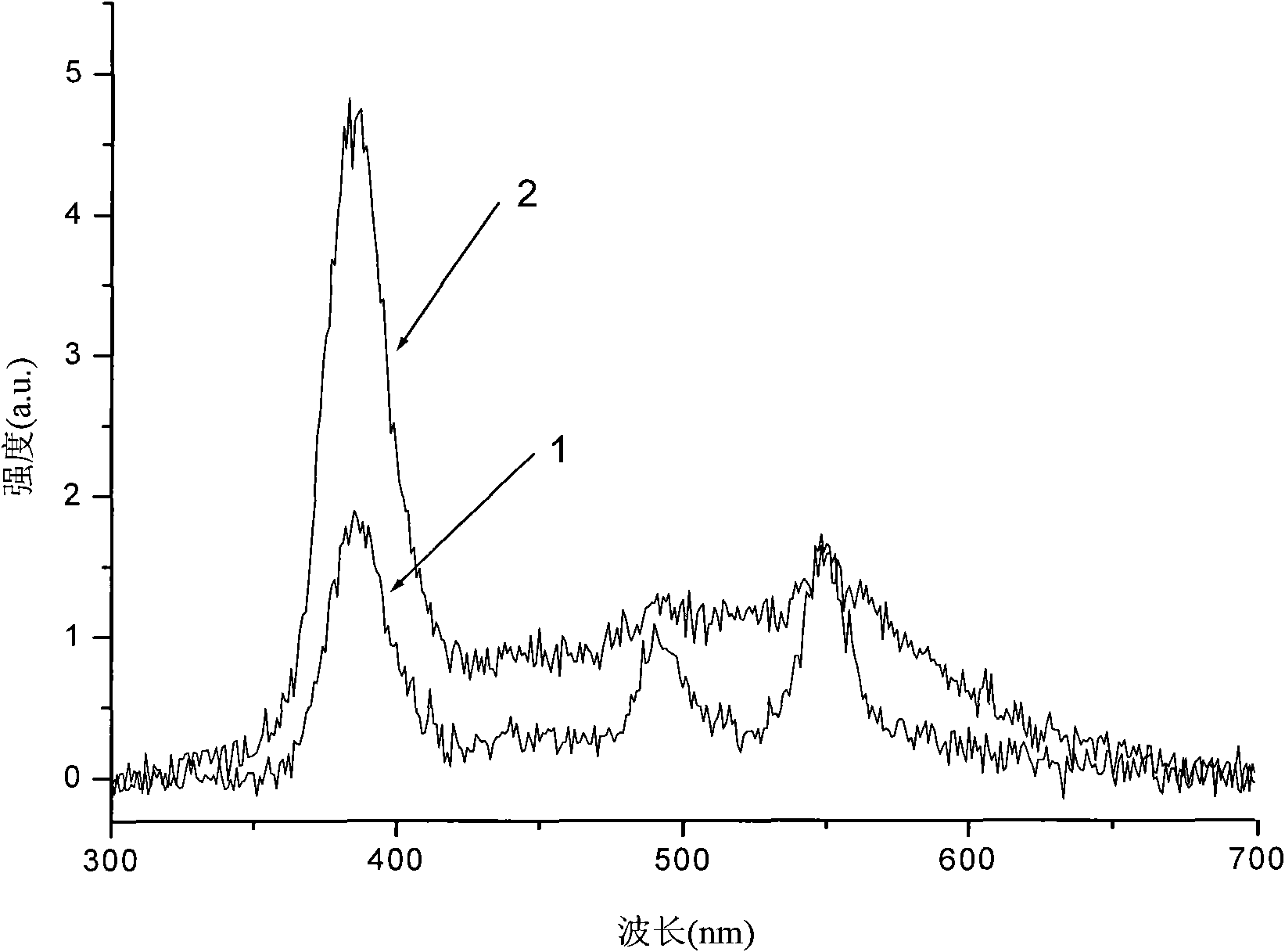

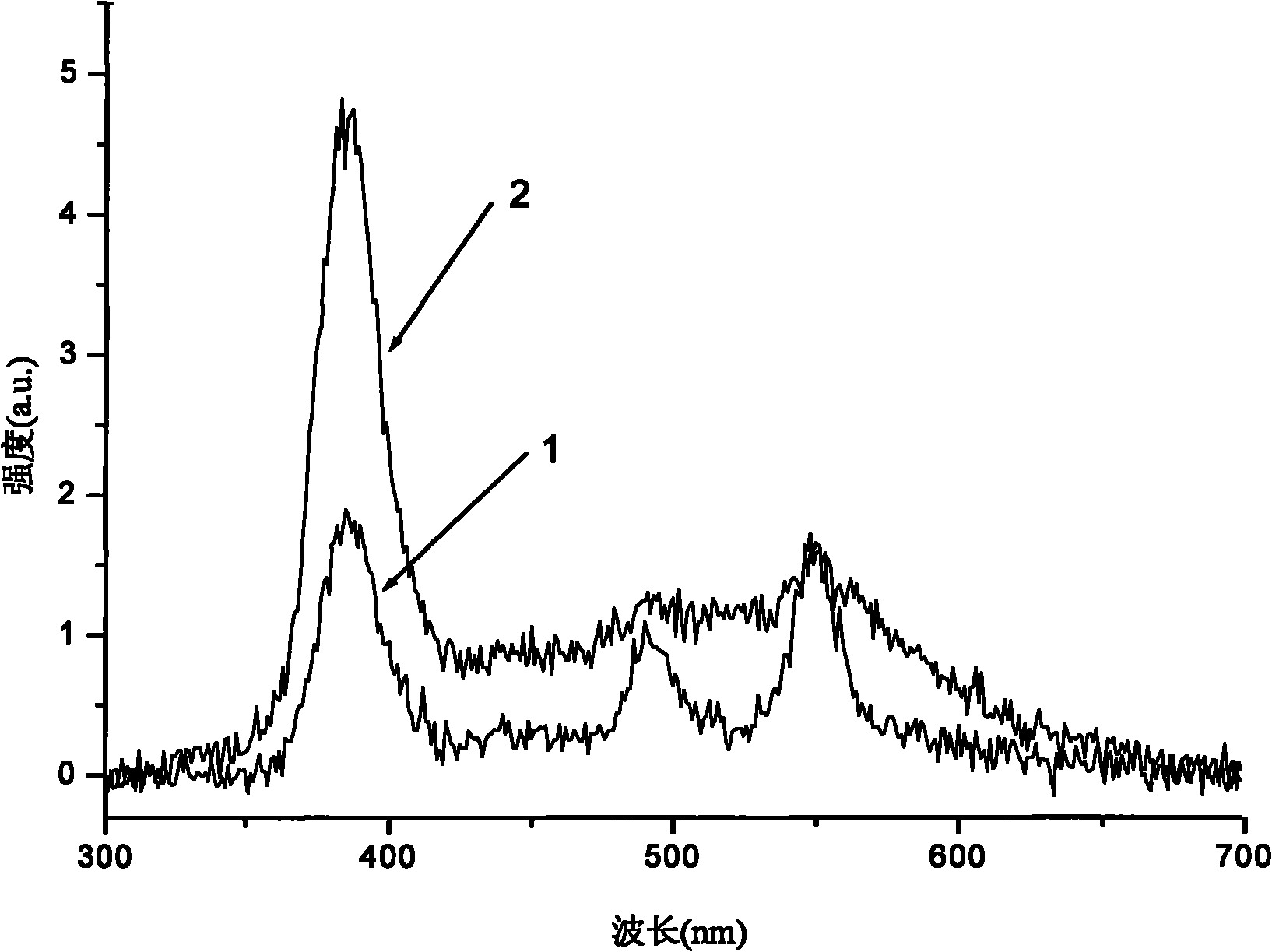

[0021] figure 1 It is a comparison chart of the luminescence spectra of the zinc oxide light-emitting element prepared in Example 1 of the present invention and the zinc oxide thin film without a metal layer under cathode ray excitation. like figure 1 As shown, 1 is the luminescence spectrum of the zinc oxide thin film without metal layer, and 2 is the luminescence spectrum of the zinc oxide light-emitting element of this embodiment. It can be seen that t...

Embodiment 2

[0023] The ZnO film was prepared by magnetron sputtering, and then a metal palladium layer with a thickness of 1 nm was deposited on the film surface by electron beam evaporation equipment, and then the ZnO film provided with the palladium layer was placed in a vacuum of 1 × 10 -4 Under a vacuum environment of Pa, annealing treatment is performed at a temperature of 200° C. for 180 minutes, and finally cooled to room temperature to obtain a zinc oxide light-emitting element with a palladium layer of a metal micro-nano structure formed on the surface.

Embodiment 3

[0025] The ZnO film was prepared by pulsed laser deposition method, and then a metal platinum layer with a thickness of 25nm was deposited on the surface of the film by magnetron sputtering equipment, and then the ZnO film with the platinum layer was placed in a vacuum of 1×10 -5 Under a vacuum environment of Pa, annealing treatment is performed at a temperature of 500° C. for 15 minutes, and finally cooled to room temperature to obtain a zinc oxide light-emitting element with a palladium layer of a metal micro-nano structure formed on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com