Zinc oxide light-emitting component and preparation method thereof

A light-emitting element, zinc oxide technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of low luminous efficiency and weak luminous brightness, and achieve high ultraviolet luminous intensity, low cost, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The ZnO film was prepared by the sol-gel method, and then a metal silver layer with a thickness of 2nm was deposited on the surface of the film by magnetron sputtering equipment, and then the ZnO film with the silver layer was placed in a vacuum of 1×10 -3 Under a vacuum environment of Pa, annealing treatment is performed at a temperature of 300° C. for 30 minutes, and finally cooled to room temperature to obtain a zinc oxide light-emitting element with a silver layer of a micro-nano structure formed on the surface.

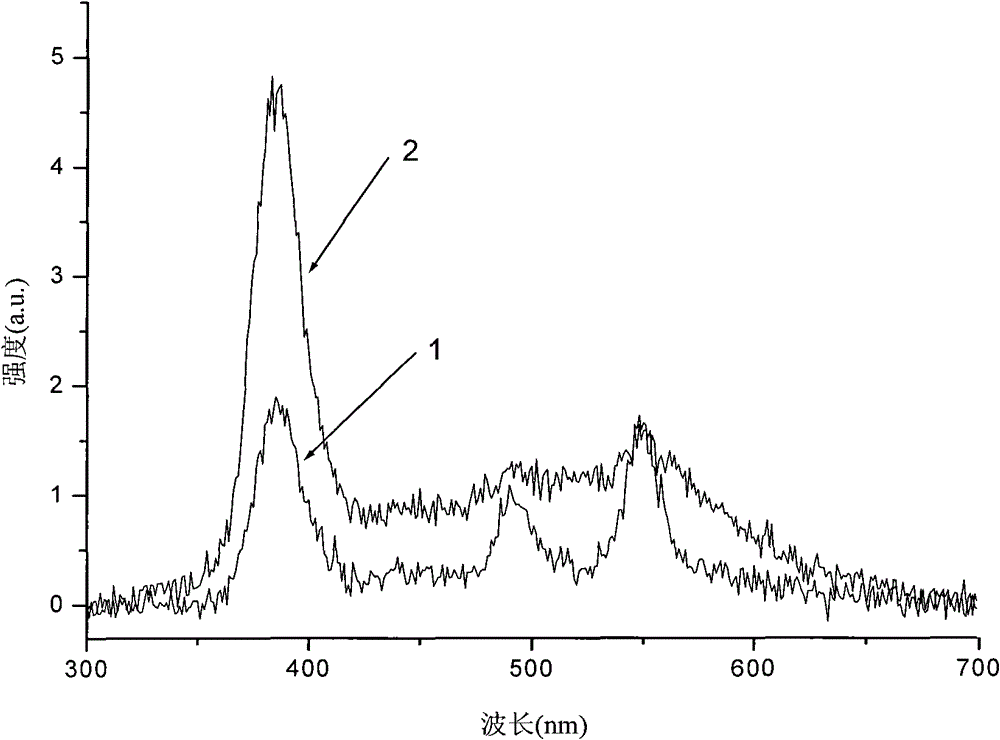

[0021] figure 1 It is a comparison chart of the luminescence spectra of the zinc oxide light-emitting element prepared in Example 1 of the present invention and the zinc oxide thin film without a metal layer under cathode ray excitation. Such as figure 1 As shown, 1 is the luminescence spectrum of the zinc oxide thin film without metal layer, and 2 is the luminescence spectrum of the zinc oxide light-emitting element of this embodiment. It can be seen tha...

Embodiment 2

[0023] The ZnO film was prepared by magnetron sputtering, and then a metal palladium layer with a thickness of 1 nm was deposited on the film surface by electron beam evaporation equipment, and then the ZnO film provided with the palladium layer was placed in a vacuum of 1 × 10 -4 Under a vacuum environment of Pa, annealing treatment is performed at a temperature of 200° C. for 180 minutes, and finally cooled to room temperature to obtain a zinc oxide light-emitting element with a palladium layer of a metal micro-nano structure formed on the surface.

Embodiment 3

[0025] The ZnO film was prepared by pulsed laser deposition method, and then a metal platinum layer with a thickness of 25nm was deposited on the surface of the film by magnetron sputtering equipment, and then the ZnO film with the platinum layer was placed in a vacuum of 1×10 -5 Under a vacuum environment of Pa, annealing treatment is performed at a temperature of 500° C. for 15 minutes, and finally cooled to room temperature to obtain a zinc oxide light-emitting element with a palladium layer of a metal micro-nano structure formed on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com